I-NY 185-800mm² I-tension clamp yocingo oluyingxube ye-aluminium ekwazi ukumelana nokushisa

Izinsimbi zokuqinisa izintambo zisetshenziselwa kakhulu ukulungisa amakhondaktha kanye namakhondaktha ombani ezintanjeni zikagesi ezihamba phezulu noma iziteshi ezincane, futhi ziwaxhume kuma-insulators acindezelayo ngokusebenzisa i-hardware yokuxhuma, noma ukuxhuma izinto ezibamba umbani emibhoshongweni.Ngokwesakhiwo esihlukile nendlela yokufaka, ihlukaniswe yaba izigaba ezine: uhlobo lwebhawodi, uhlobo lokucindezela kanye nohlobo lwe-wedge, kanye nohlobo olusontelwe ngaphambili.

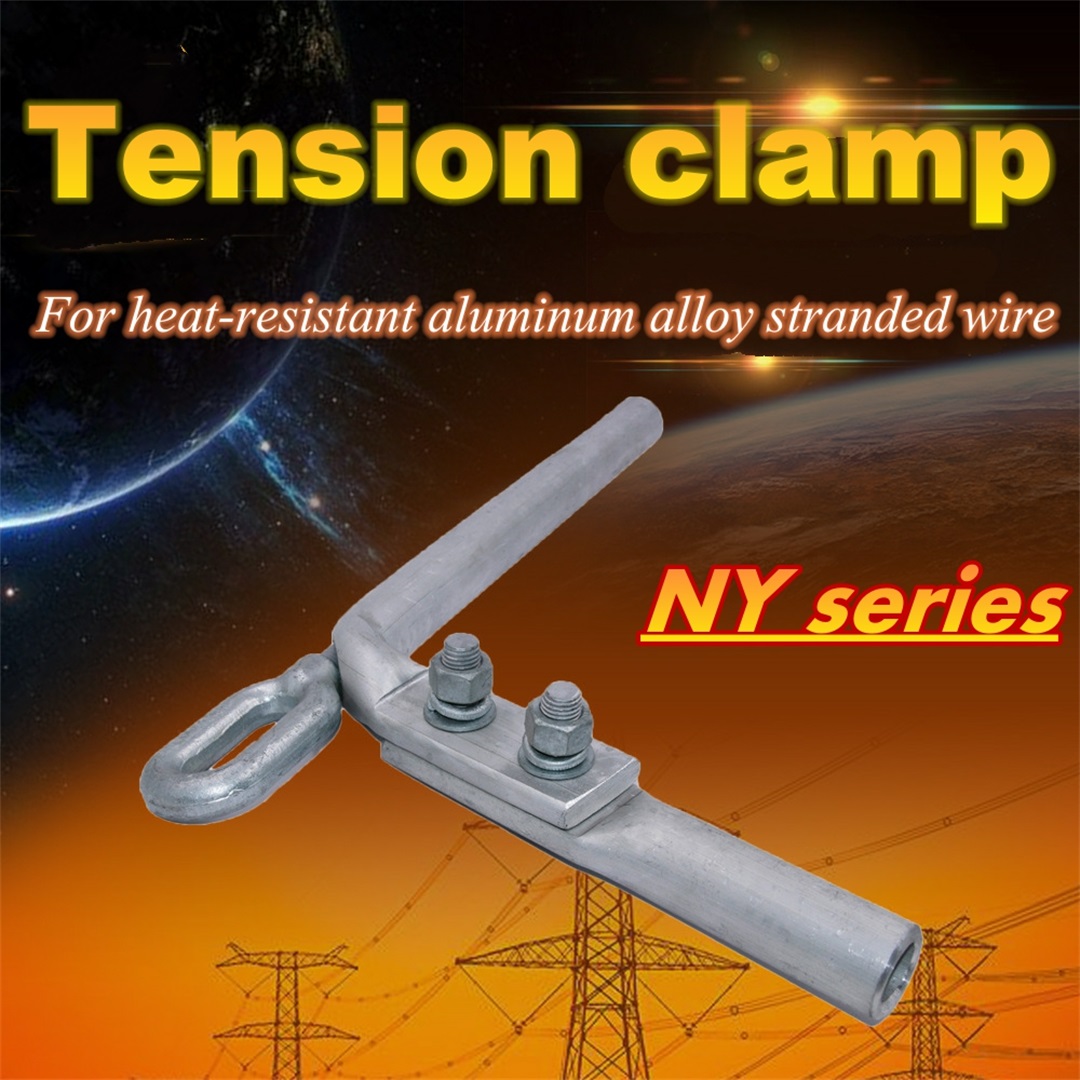

I-NY tension clamp (uhlobo lwe-hydraulic, steel anchor welding) isetshenziswa kakhulu ukulungisa intambo ukuze ithwale ukushuba kocingo, futhi ilengise ucingo ku-hardware ontanjeni ye-tension noma umbhoshongo.

Incazelo Yomkhiqizo

Izici zomkhiqizo kanye nezindaba zokufaka

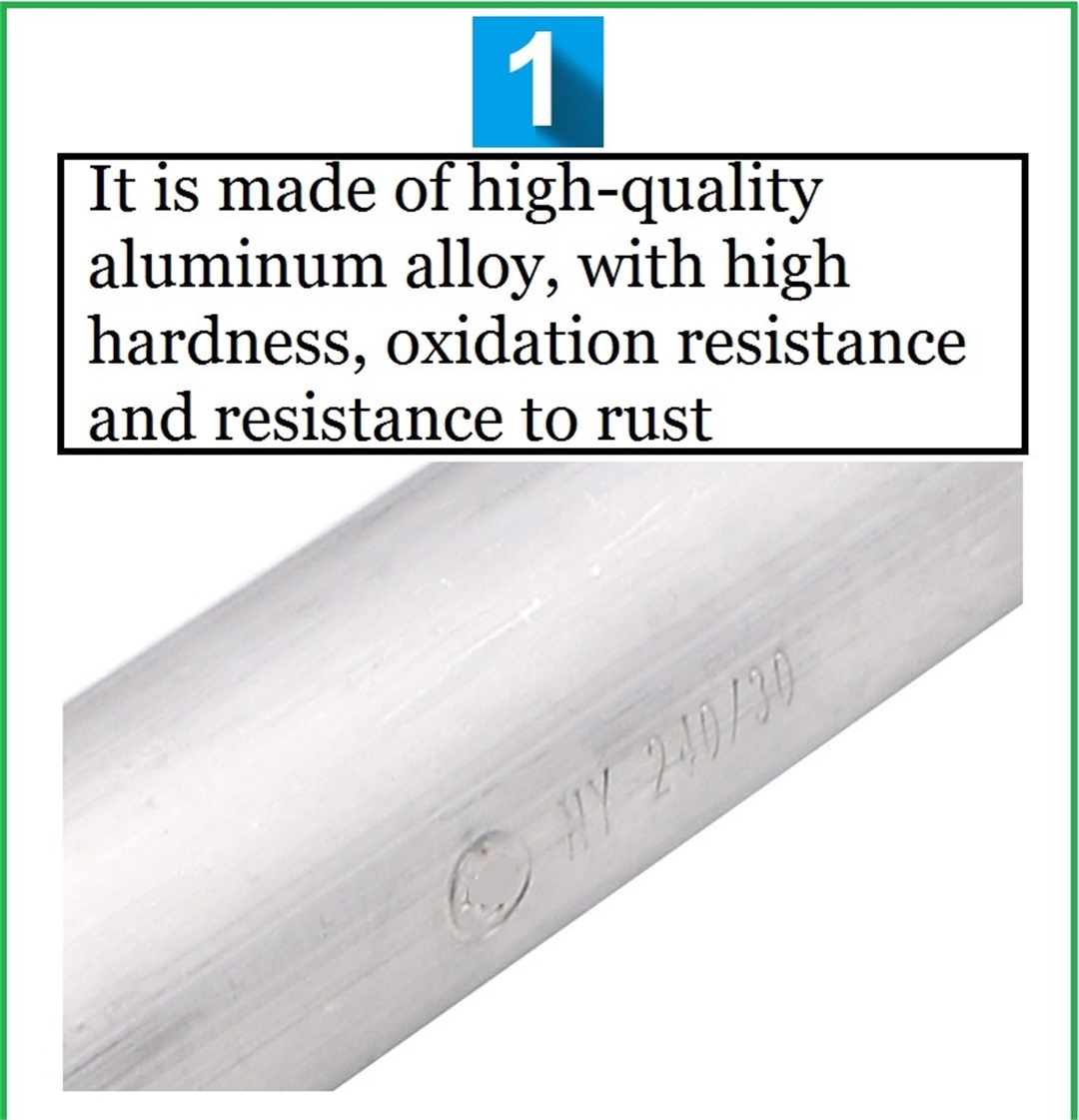

Izici:

a.Umzimba wesiqeshana wenziwe ngezinto ezisezingeni eliphezulu ze-aluminium.

b.Ukubukeka kuhle futhi impilo yesevisi yinde.

c.Kulula ukufaka nokusebenzisa.

d.Akukho ukulahlekelwa kwe-hysteresis, futhi kuwumkhiqizo oqinisekisiwe onekhabhoni ephansi, ukonga amandla.

Ukufakwa okubalulekile:

1. Hlanza ingxenye eyodwa yocingo olucijile isikhathi esingaba yi-1m bese ugcoba igrisi.

2. Faka ishubhu le-aluminium elihlanziwe (ububanzi obungaphandle D) ekugcineni kocingo bese ulidonsa ibanga elingu-1m ukusuka ekugcineni kocingo.3. Sebenzisa i-vernier caliper noma i-tape measure ukuze ulinganise usayizi l 2 weshubhu yangaphambili yehange lensimbi, ulinganise ubude benkango yensimbi okufanele ikhishwe ekugcineni kwe-O yocingo ON= l 2 + Δl mm. (Δl ingu-15mm), yenza umaki, futhi uyibophe ebangeni elingama-20mm ukusuka kophawu Thatha intambo esanda kuboshwa P. 4. Vula ingxenye ye-aluminium strand ekugcineni u-O, bese ubophela isiphetho sensimbi esiveziwe nge ucingo lokubopha.Bese usebenzisa i-cutter (noma i-aluminium stripper) ukuze usike imicu ye-aluminium yangaphandle naphakathi endaweni yophawu N. Lapho usika imicu ye-aluminium yangaphakathi, usike kuphela ku-3/4 wobubanzi bomucu ngamunye, bese uphula imicu eyodwa ye-aluminium. ngomunye.Lapho ukhumula ucingo lwe-aluminium, kwenqatshelwe ngokuphelele ukulimaza umgogodla wensimbi.)

5. Khipha ihange lensimbi

A. Khetha idayizi yepayipi yensimbi ethi "Cd#" ehambisana nodayamitha wangaphandle d wehange lensimbi.Imiyalo yokufaka ye-NY tension clamp kufanele iqinisekise ukuthi i-engeli ediagonal ye-hexagonal die ithi dmm;

B. Cindezela insimbi Ngemva kokuba umgogodla usuhlanziwe, zungezisa bese uwufaka ngaphansi kwehange lensimbi eduze nohlangothi olubambekayo lwenkango yensimbi, futhi

ukuphela kwehange lensimbi kuveza umgogodla wensimbi ngobude obungaba ngu-15mm;Ngalesi sikhathi, izintambo ezinhlangothini zombili kufanele zibe

igcinwe ivundlile nehange lensimbi, futhi ihambisana ne-axis yomshini wokucindezela we-hydraulic, ukuze kuncishiswe ukugoba okungenzeka kwepayipi ngemva kokucindezelwa.

D. Khipha ipayipi elingaphambili lehange lensimbi.Isiqondiso se-crimping sisuka emgodini wepayipi ukuya emlonyeni wepayipi.Lapho usebenzisa ingcindezi, isikhunta ezimbili eziseduze

kufanele idlule okungenani 5-10mm.Ngemva kokucindezelwa kuhexagon evamile, ibanga S phakathi kwezinhlangothi eziphambene zeheksagoni evamile kufanele liqinisekiswe.Inani elivumelekile lika-S lithi: S=(0.866*0.993d)+0.2.Ngemuva kokubumba, sebenzisa i-caliper ejwayelekile ukuze uhlole usayizi webanga eliphambene ngemuva kokucindezela.(Qaphela: Ingcindezi yangempela yepompo ye-hydraulic akufanele ibe ngaphansi kuka-80Mp, futhi lapho ingcindezi ifinyelela inani elishiwo, kufanele igcinwe ku-3-5s).Qhubeka nokusebenza kwe-hydraulic kuphela ngemuva kokuthi izinga selifinyelelwe.

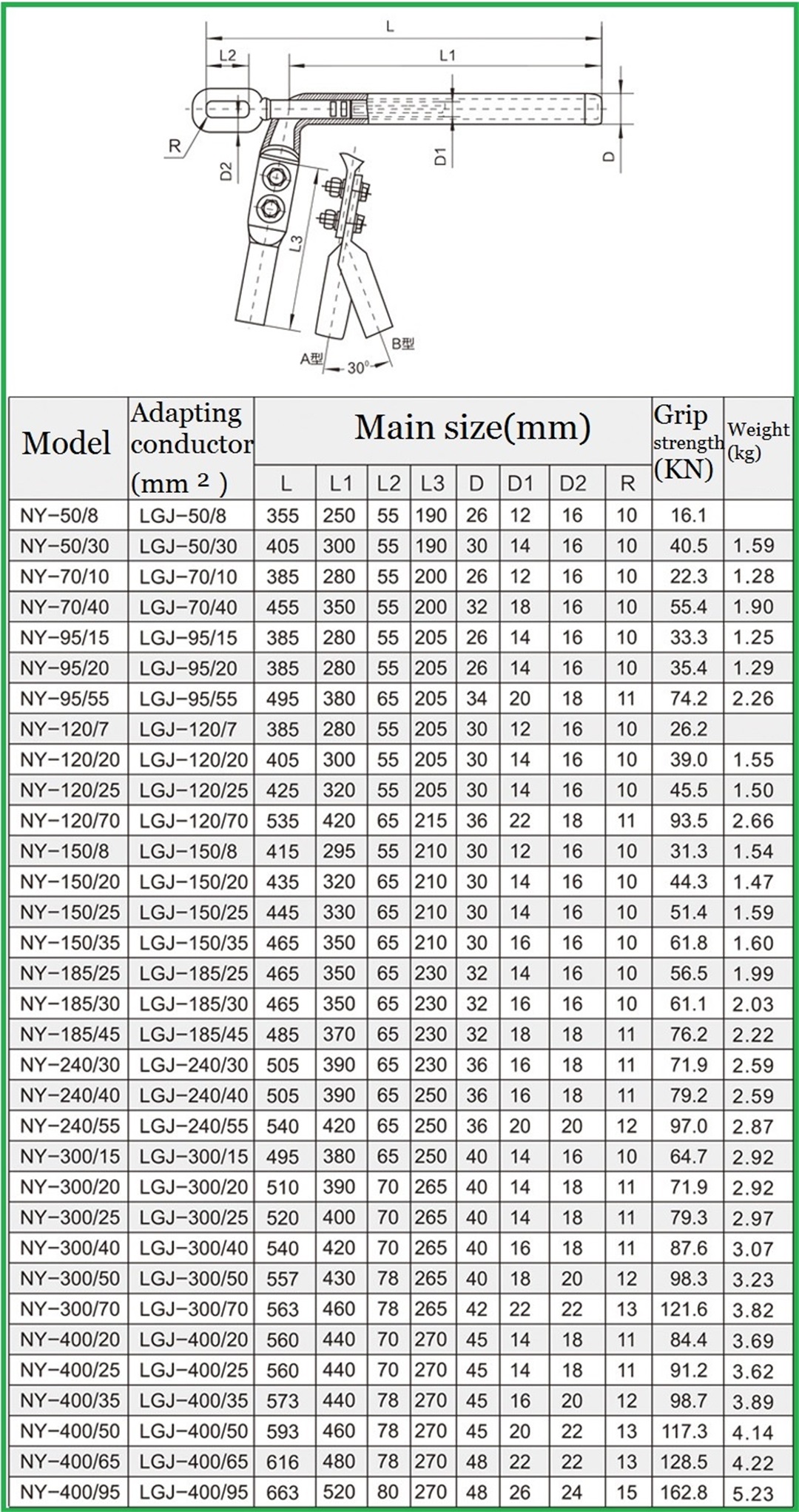

Imininingwane yomkhiqizo

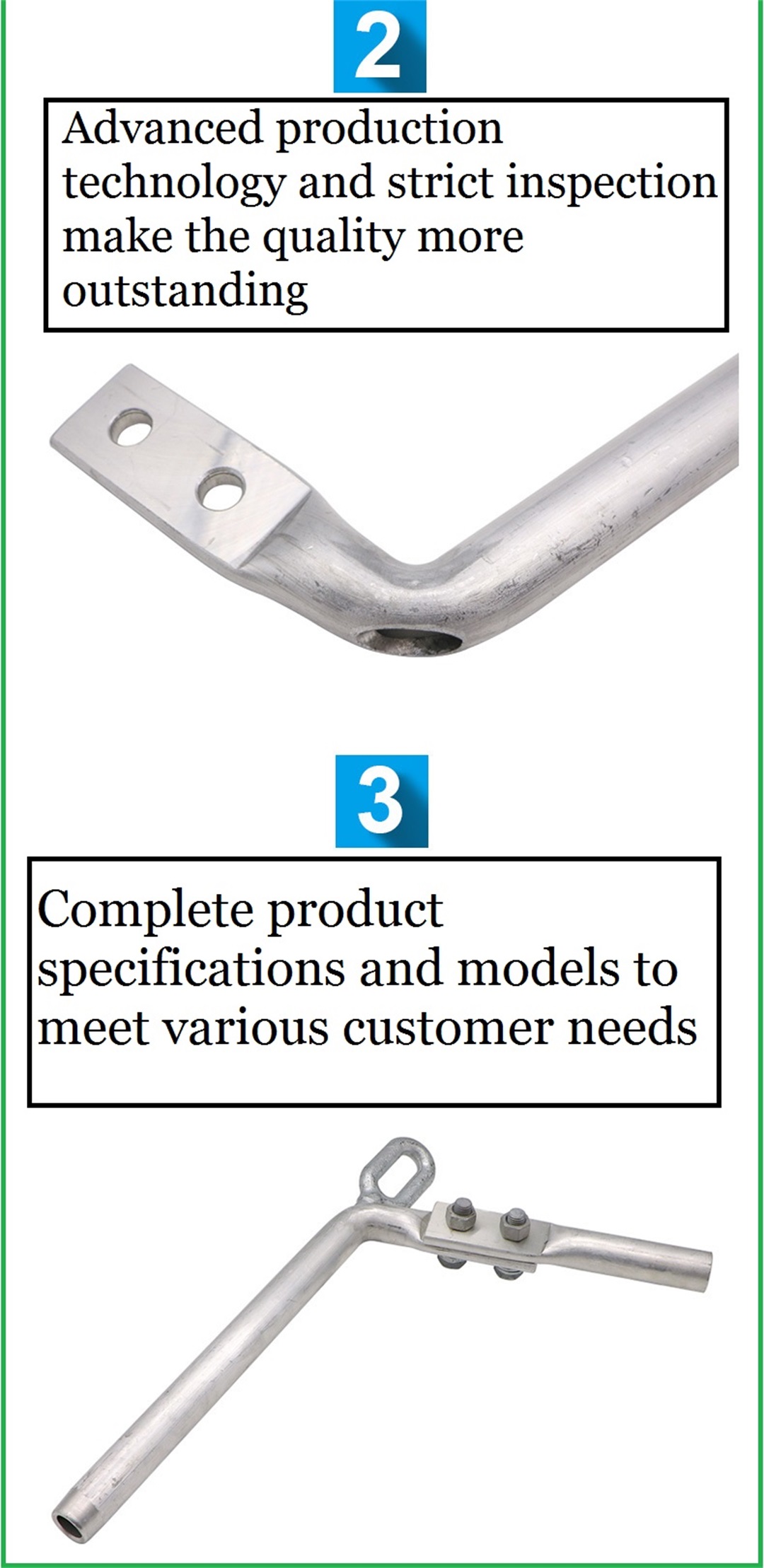

Imikhiqizo shot real

Ikhona leshabhu yokukhiqiza

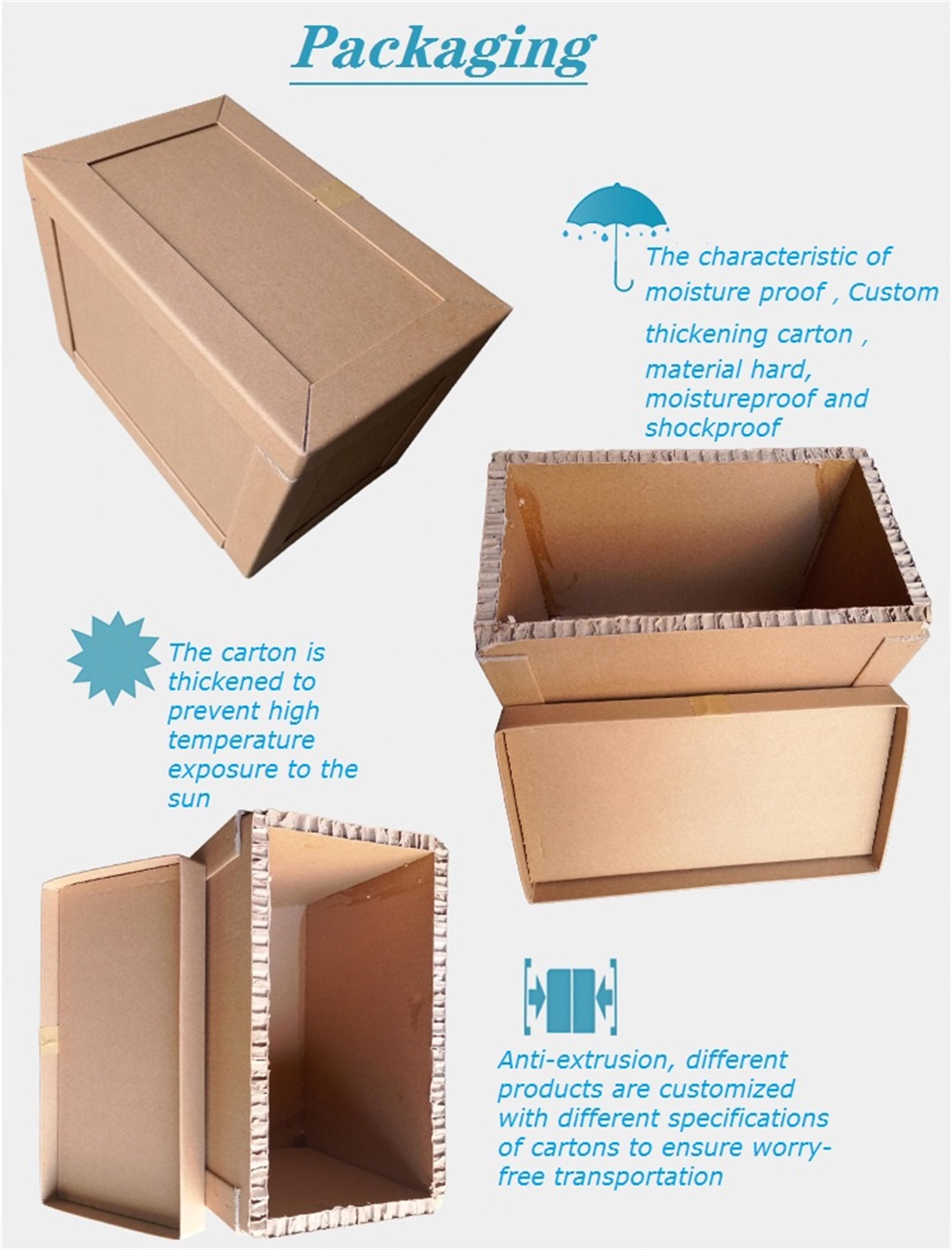

Ukupakishwa komkhiqizo

Ikesi lesicelo somkhiqizo