I-KSG 6-10KV 50-1600KVA 400-1200V uhlobo oluvamile lwemayini eyomile yohlobo lwe-transformer

Incazelo Yomkhiqizo

I-KSG series mine mine-type transformer ilungele iziteshi ezimaphakathi, amayadi angaphansi komhlaba, izindawo zokungena komoya ezivamile kanye nezindawo zomoya eziyinhloko ezimayini zamalahle.Izimayini zensimbi nezingezona zensimbi ezinegesi kodwa ezingenabungozi bokuqhuma zisetshenziselwa ukuhlinzeka ngogesi emishinini ehlukahlukene ezimayini nasezimayini ezingaphansi komhlaba, futhi ziphinde zisetshenziselwe ukuphehla imigudu yezitimela zomphakathi.

Iziguquli zochungechunge lwezimayini zohlobo olomile lwe-KSG zingama-transformer ohlobo olomile anegobolondo lebanga lokuvikela le-IP20 futhi angasetshenziswa ngokuhlanganiswa namaswishi kagesi aphezulu naphansi.I-transformer evamile yohlobo olomile yezimayini yakhiwe i-transformer yohlobo olomile oluhlukile, igobolondo nekhebula.Isetshenziswa njengamandla angaphansi komhlaba kanye nemishini yesiteshi esincane, okuyi-transformer yohlobo olomile lokumba izimayini.I-transformer yohlobo olomile yeziteshi eziphathwayo zenjongo evamile yokumba izimayini ayinayo Uma ifakwe amaswishi kagesi aphezulu naphansi, ingxenye yecala eliphakathi ifakwe umgogodla we-transformer, okungukuthi, ingxenye ejikajikayo kanye nengxenye yensimbi ewumgogodla.

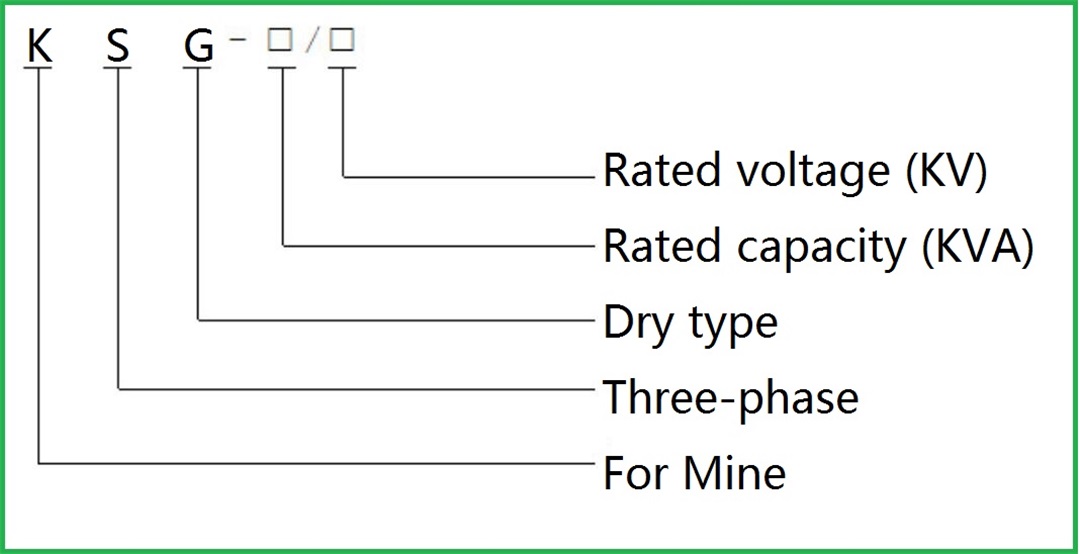

Incazelo Yemodeli

Izici zomkhiqizo kanye nobubanzi bokusetshenziswa

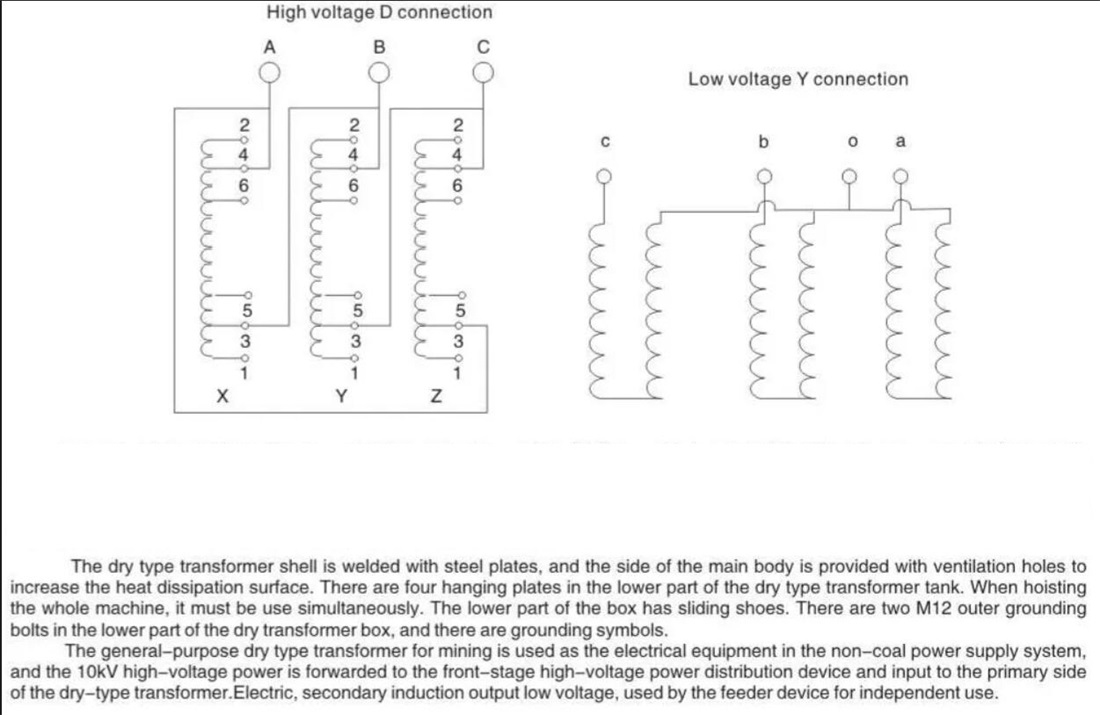

isakhiwo somkhiqizo:

I-transformer evamile yohlobo olomile yezimayini yakhiwe i-transformer yohlobo olomile oluhlukile, igobolondo nekhebula.Isetshenziswa njengamandla angaphansi komhlaba kanye nemishini yesiteshi esincane, okuyi-transformer yohlobo olomile lokumba izimayini.I-transformer yohlobo olomile yeziteshi eziphathwayo zenjongo evamile yokumba izimayini ayinayo Uma ifakwe amaswishi kagesi aphezulu naphansi, ingxenye yecala eliphakathi ifakwe umgogodla we-transformer, okungukuthi, ingxenye ejikajikayo kanye nengxenye yensimbi ewumgogodla.

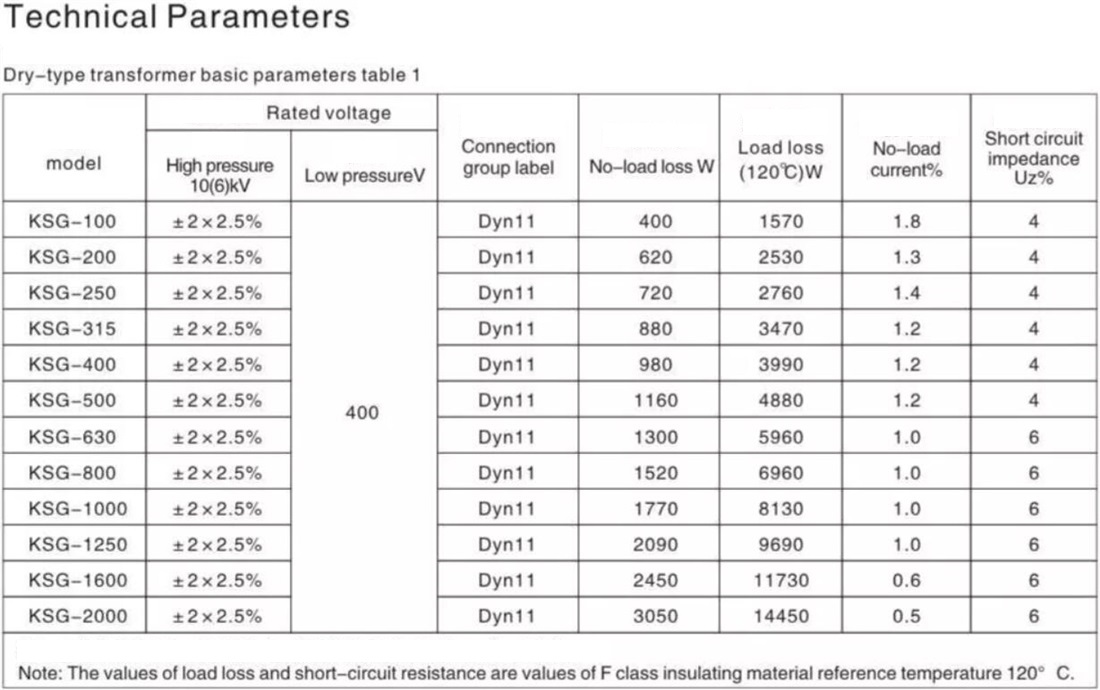

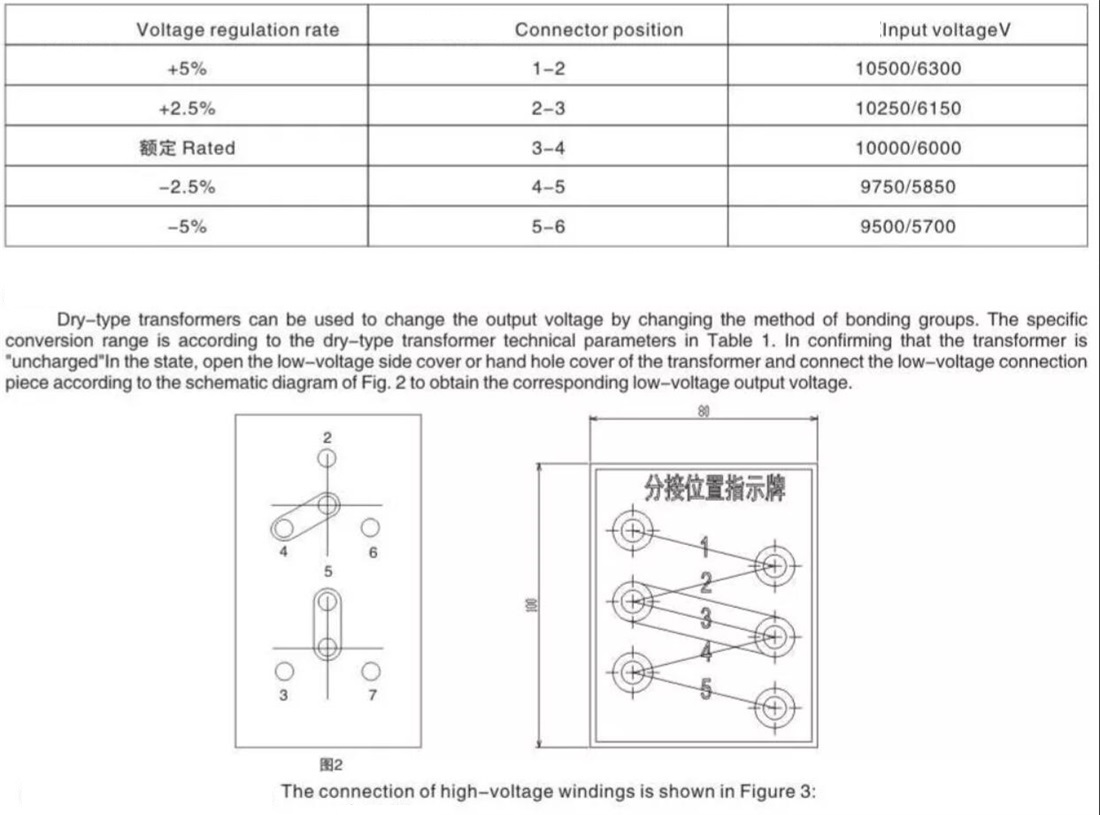

I-voltage yokufaka ye-transformer yohlobo olomile ingakwazi ukwamukela i-voltage yomugqa ukusuka ku-+5% kuya ku-5% we-voltage elinganiselwe.Uma kudingekile ukushintsha i-high-voltage kampompi kampompi wokufaka, vula ikhava yebhokisi le-high-voltage junction ebhokisini ngemva kokuqinisekisa ukuthi i-transformer ayinawo amandla, futhi ushintshe indawo yokuxhuma ucezu lokuxhuma ebhodini lompompi lamandla kagesi aphezulu ngokusho. kuya kuThebula 4. Lapho ushiya imboni, izingcezu zokuxhuma zihlala ku-4-5, okungukuthi, i-voltage yokufaka elinganiselwe yi-10000V.

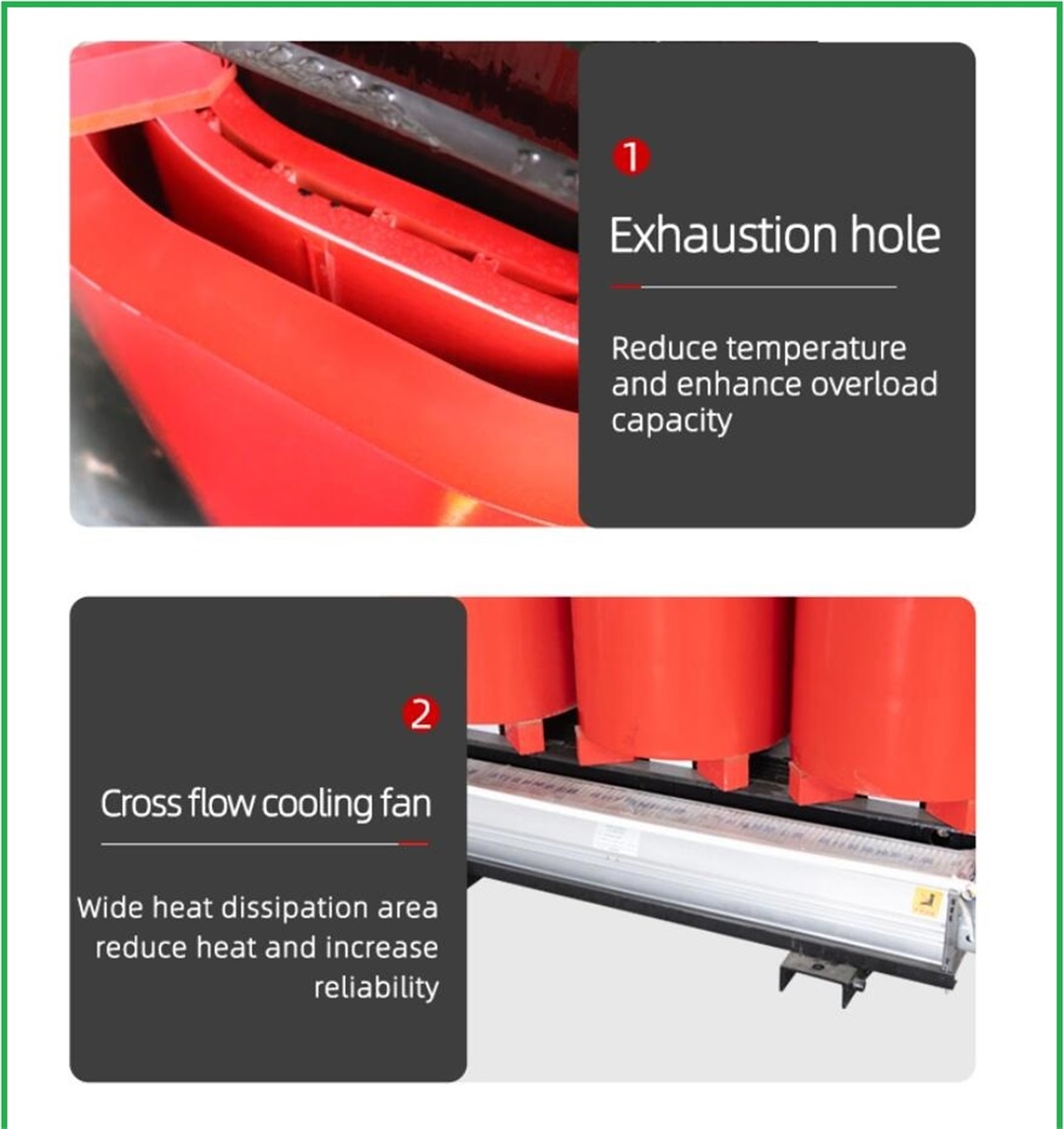

Ikesi ye-transformer yohlobo olomile ishiselwe ngamapuleti ensimbi, futhi izimbobo zokungenisa umoya zengezwa ohlangothini lomzimba omkhulu ukuze kwandiswe indawo yokukhipha ukushisa.Kunamapuleti amane alengayo engxenyeni engezansi yebhokisi le-transformer yohlobo olomile, okufanele asetshenziswe ngesikhathi esifanayo lapho uphakamisa umshini wonke.Ingxenye engezansi yebhokisi inikezwe isicathulo esishelelayo.Ingxenye engezansi yebhokisi le-transformer yohlobo olomile ihlinzekwa ngamabhawodi amabili angaphandle angama-M12 anezimpawu zokubeka phansi.

I-transformer yohlobo olujwayelekile yohlobo olomile esetshenziswa ezimayini isetshenziswa njengempahla kagesi ohlelweni lokuphakela amandla ezimayini ezingezona zamalahle.I-feeder ehlukile isetshenziselwa okokusebenza.

Izinzuzo zomkhiqizo kanye nezimpawu:

1. Ama-transformer ohlobo lwezimayini ezomile ze-KSG anezinzuzo zokuphepha, okuthembekile, ukonga amandla, ukuvikela umlilo kanye nokuvikela ukuqhuma, awekho amagesi ayingozi, akukho ukungcoliswa kwemvelo, kanye nokugcinwa okulula.

2. Izinkomba zokusebenza komkhiqizo ziphakeme, zigcina izici ezinhle kakhulu zikagesi nemishini phakathi nayo yonke impilo yesevisi.Ifaneleka kakhulu ezindaweni ezinezidingo eziphakeme zokuvikela umlilo, ukuguquguquka okukhulu komthwalo kanye namazinga aphezulu okumelana nokushisa.

3. Umgogodla wensimbi we-KSG mine transformer wenziwe ngeshidi lensimbi yensimbi ye-silicon esezingeni eliphezulu nesezingeni eliphakeme, enamalunga amancane, ukulahlekelwa okuphansi nomsindo ophansi.Ikhoyili ithatha ubuchwepheshe bokuvunguza obuphambili kakhulu, futhi izinto zokuvikela ukumelana nokushisa zisetshenziswa phakathi kwezingqimba nokujika.Amamaki e-insulation angamamaki F kanye no-H amelana nokushisa, angasetshenziswa isikhathi eside ngaphansi kwemvelo engu-180°.

4. Ikhoyili iyivacuum ecwiliswe ngopende ongenisiwe, futhi upende wokucwilisa ungena ngokuphelele ungqimba olujulile lwekhoyili.160 ℃ ~ 170 ℃ ukomisa nokwelapha, amandla aphezulu emishini.Umzimba womiswe ngendlela yokucindezela okuguquguqukayo, futhi ingaphezulu lomzimba limbozwe ungqimba lukapende olumelene nomswakama, olunezici ezinhle zokuhlukanisa.

izimo zokusebenza ezijwayelekile:

Iziguquli zohlobo olomile kufanele zisebenze ngokujwayelekile ngaphansi kwezimo ezilandelayo:

a) Ukuphakama: akukho ngaphezu kwe-1000m;

b) Izinga lokushisa le-ambient: -20℃~+40℃

c) Umswakama ohlobene womoya aweqi ama-95% (ku +25°C);

d) endaweni yegesi noma umhwamuko ongonakalisi okokuvikela;

e) Izosetshenziswa ezindaweni eziqhumayo ngaphandle kothuli lwe-methane.

Ukufakwa nokusetshenziswa komkhiqizo

Ukufakwa nokusetshenziswa:

Yenza ukuhlola okuphelele komkhiqizo kanye nezivivinyo zikagesi ezidingekayo ngaphambi kokufakwa

1. Faka i-transformer yohlobo lwemayini eyomile

(1) Indawo yokufaka

1.1 I-transformer kufanele ifakwe eduze nendawo yokulayisha.

1.2 Izinga lokuvikela legumbi le-transformer kufanele lihlangabezane nezimfuneko zeleveli yokuvikela ye-IP20.Amagesi abolayo kanye nezinhlayiya zothuli kufanele kuvinjelwe ekuhlaseleni i-transformer.

(2) Isisekelo sokufakwa

2.1 Isisekelo se-transformer kumele sikwazi ukumelana nesisindo esigcwele se-transformer.

2.2 Isisekelo se-transformer sizohlangabezana nezidingo zamakhodi kazwelonke wokwakha.

(3) Ukuvikela ukushaqeka kukagesi nebanga lokuphepha

3.1 Idizayini yokufaka i-transformer kufanele ihlangabezane nezidingo zokuphepha komuntu siqu, futhi kufanele kuqinisekiswe ukuthi i-transformer ayikwazi ukuthintwa abantu ngesikhathi sokusebenza.Ibanga elincane eliphephile phakathi kwemizimba ekhokhiswayo naphakathi kwemizimba ephilayo nendawo kufanele lihlangabezane nezidingo zemithetho kazwelonke yokuphakelwa kukagesi.Ukwengeza, ibanga elincane eliphephile phakathi kwezintambo nezintambo zamandla kagesi aphezulu, izintambo zokulawula izinga lokushisa, izintambo zamafeni namakhoyili anamandla kagesi aphezulu kufanele kuqinisekiswe..

3.2 Ukuze kube lula ukufakwa, ukulungiswa kanye nokuhlolwa emsebenzini, umzila kufanele ushiywe phakathi kwe-transformer nodonga.

3.3 Kumelwe kube negebe elingaphezu kwe-1m (ibanga lomkhawulo wangaphandle) phakathi kwama-transformer aseduze.

3.4 Indawo yokufaka i-transformer kufanele ibe lula kubasebenzi abasemsebenzini ukuthi babheke futhi balinganise ithuluzi endaweni ephephile.

(4) Ukungenisa umoya

4.1 Kufanele kube nezinsiza ezanele zokungenisa umoya ekamelweni le-transformer ukuze kuqinisekiswe ukuthi ukushisa okukhiqizwa yi-transformer kukhishwa ngesikhathi.

4.2 Isidingo somoya opholile, ukugeleza komoya cishe ku-3m3/min ngokulahleka kwe-kilowatt ngayinye, futhi umthamo wokungenisa umoya unqunywa ngokuvumelana nenani eliphelele lokulahlekelwa kwe-transformer.

4.3 I-transformer kufanele ifakwe i-600mm kude nodonga ukuze kuqinisekiswe ukuhamba komoya eduze kwe-transformer kanye nezidingo zokuphepha komuntu siqu.

4.4 Uthango noma amashutha endaweni yokungena komoya kanye nendawo yokuphuma ngeke yehlise ukuphambana kwesigaba esisebenzayo sokuhamba.

Kumele kube nezinyathelo zokuvimbela ukungena kwezinto zangaphandle.

(5) Ngaphansi kwezimo ezijwayelekile, i-transformer ayidingi ukufakwa ngama-bolts onyawo, kodwa uma kunesidingo sokulwa nokudlidliza, kuyadingeka ukufaka ama-bolts onyawo ngaphambi kokungcwatshwa ngokusho kobukhulu bangaphandle.

(6) Ukuxhunywa kwezintambo zikagesi

6.1 Ngaphambi kokuxhuma wonke amatheminali, kufanele ujwayele umbiko wokuhlola kanye nomdwebo wokuxhuma ku-nameplate, futhi ukuxhumana kufanele kube okulungile.

6.2 Ulayini wokuxhuma owenziwe ngamakhebula noma amabhasi kufanele uhambisane nezidingo zemithethonqubo yokusebenza kwe-transformer kanye nemithetho yokufaka ugesi, futhi ukhethe izintambo namabhasi aneziphambano ezifanele.

6.3 Intambo yokuxhuma akufanele idale ukushuba okukhulu kwemishini kanye netorque kutheminali.Lapho i-current ingaphezu kwama-amps angu-1000, kufanele kube nokuxhumana okuthambile phakathi kwe-busbar namatheminali e-transformer ukuze kunxeshezelwe ukucindezeleka okukhiqizwa ama-conductor ngesikhathi sokwanda nokunciphisa ukushisa.

6.4 Ibanga eliphansi lokuhlukanisa phakathi kwezinto eziphilayo naphakathi kwezinto eziphilayo nomhlaba kufanele liqinisekiswe, ikakhulukazi ibanga eliphakathi kwezintambo namakhoyili anamandla kagesi.

6.5 Ukuxhunywa kwebhawodi kufanele kuqinisekise ingcindezi eyanele yokuxhumana, futhi iwasha uvemvane noma iwasha yasentwasahlobo ingasetshenziswa.

6.6 Ngaphambi kokufakwa kwezintambo, wonke amabhawodi axhumayo namabhulokhi agcinayo kufanele ahlanzwe.Konke ukuxhumana kufanele kube okuqinile futhi okuthembekile.

6.7 Ngetheminali ephumayo eholayo yolayini wegatsha lekhoyili enamandla amakhulu, amandla kufanele afane lapho kuxhunywa, futhi awevunyelwe ngokuphelele amandla okushayisana namandla okugoba ukuthi asebenze kutheminali.

(7) Umhlaba

I-7.1 Kukhona i-grounding bolt ngaphansi kwe-transformer, okumele ixhunywe ohlelweni lokuvikela phansi.

7.2 Inani lokumelana nesisekelo sohlelo lokuvikela umhlabathi kanye nengxenye yesiphambano socingo oluphansi kufanele luhambisane nemithetho yokufaka ugesi.

(8) Ukufakwa nokusetshenziswa kwesistimu yokulawula izinga lokushisa

8.1 Ngenxa yokuthi umkhiqizo ufakwe i-thermometer yesignali, ingakwazi ukubona imisebenzi yephutha, umsindo wezinga lokushisa elingaphezulu kanye ne-alamu yokukhanya, ukukhubeka okuzenzakalelayo okudlula izinga lokushisa kanye nokuvula nokuvala ifeni ngokuzenzakalelayo.

8.2 Ithemometha yesiginali kanye nokumelana neplatinamu kufakwe ngaphambi kokuba umkhiqizo uphume efektri, futhi izintambo zesiphephetha-moya kanye nethemometha yesignali sekuqediwe, okungukuthi, inani lokushisa le-alamu ye-thermometer yezinga lokushisa elingaphezu kokushisa nohambo lwezinga lokushisa elingaphezu kwamandla, futhi ifeni iyaziqala futhi ime.Lapho ufaka, umsebenzisi udinga kuphela ukuvula ukunikezwa kwamandla ngokuya ngemanuwali yemiyalelo yokufaka noma ilogo yethemometha yesignali, futhi axhume isiphetho sesignali ye-alamu.

2. Ukulungisa iphutha

(1)Ngaphambi kokufaka i-transformer yohlobo olomile emgodini ophansi, qala ngokulungisa indawo yetheminali kampompi yokufaka i-voltage ephezulu ye-transformer ibe sesimweni esifanele ngokwezinga lokuphakelwa kukagesi we-downhole futhi ubhekisele emiyalweni.

(2) Lapho i-transformer yohlobo olomile ifakwa ku-voltage egcwele futhi akukho-mthwalo, i-inrush current (i-impulse current) ingase yenziwe.I-inrush current ihlobene nokuphazamiseka kukagesi kolayini kanye nevelu esheshayo ye-voltage lapho uvala, ngokuvamile asikho ngaphezu kwezikhathi ezi-5 ezilinganiselwe zamanje zamandla kagesi aphezulu, futhi i-inrush current ibola ngokushesha., ngezinye izikhathi imizuzwana embalwa.

Ukusetshenziswa kanye nokusebenza:

1. Hlola

1.1 Ukubukeka, hlola ikhoyili ye-transformer, izintambo zikagesi eziphakeme neziphansi kanye nokuxhunywayo ukuze kubonakale umonakalo noma ukuxega.

1.2 Hlola ukuthi idatha eku-nameplate iyahlangabezana yini nezimfuneko zoku-oda.

1.3 Hlola ukuthi isikhwama se-transformer kanye ne-iron core kusekelwe unomphela.

1.4 Hlola ukuthi idivayisi yokulawula izinga lokushisa kanye nedivayisi yokupholisa umoya kuqedile yini.

1.5 Bheka ukuthi umbiko wokuhlolwa kwefekthri uphelele yini.

1.6 Hlola ukuthi zikhona yini izinto zangaphandle kumongo wensimbi kanye nekhoyili, nokuthi kukhona yini uthuli noma izinto zangaphandle emgudwini womoya.

1.7 Ngaphambi kokusebenza, sebenzisa umoya ocindezelwe ukuze uhlanze ikhoyili ye-transformer, i-iron core kanye nephaseji lomoya.

1.8 Hlola ibanga phakathi kolayini wokulawula izinga lokushisa nengxenye ngayinye, futhi ngemva kokuqinisekisa ukuthi ilungile ingafakwa esivivinyweni.

2. Isivivinyo

2.1 Ukuhlolwa kokumelana nokufakwa kwe-core:

Khipha okwesikhashana i-transformer core kusukela ku-clamp ephezulu (buyela esimweni sangempela ngemva kokulinganisa), futhi ulinganise nge-500V megohmmeter (umswakama ohlobene ≤85%).

Insimbi core-clamp nomhlabathi ≥5MΩ.

2.2 Isivivinyo sokumelana nokufakwa kwamakhoyili (izinga lokushisa elingu-10℃-40℃, umswakama ohlobene ≤85%), likala nge-megohmmeter engu-2500V, ukumelana nokufakwa okumazombe phansi phansi:

I-voltage ephezulu yokujika ukuya phansi ≥1000MΩ

I-voltage ephansi yokujika ukuya phansi ≥1000MΩ

I-voltage ephezulu ejikajikayo iye kuma-voltage aphansi amawindi ≥1000MΩ

Endaweni enomswakama uma kuqhathaniswa, ukumelana ne-insulation kuzokwehla.Ngokuvamile, uma ukumelana nokufakwa kwe-insulation kungekho ngaphansi kuka-2 MΩ (ukufunda ku-25°C ngeminithi elingu-1) nge-1kV ngayinye ye-voltage elinganiselwe, ingahlangabezana nezidingo zokusebenza.Kodwa-ke, lapho i-transformer imanzi kakhulu, kungakhathaliseki ukuthi iphikisana nokufakwa kwayo, kufanele yomiswe ngaphambi kokuhlolwa kwe-voltage noma iqale ukusebenza.

2.3 Izinga lokungalingani kokuhlolwa kokumelana ne-DC: isigaba singu-4%;ulayini ungu-2%.

2.4 Ukuhlolwa kwesilinganiso se-Transformer: ngaphansi noma kulingana no-±0.5%.

2.5 Imvamisa yokwakhiwa kwangaphandle imelana nokuhlolwa kwe-voltage, i-standard voltage ingama-85% wezinga lokuhlola lasefekthri.

2.6 Yenza ukuhlolwa kwefrikhwensi yamandla okumelana ne-voltage ku-transformer efakwe i-thermostat.Wonke ama-probe aku-thermostat kufanele akhishwe ngaphambi kokuhlolwa.

3. Faka ekusebenzeni

3.1 Isikhathi sokuqala ngqa i-thermostat esetshenziswa ngayo: Ithuluzi lokulawula izinga lokushisa lilungiselwe izinga lokushisa elihambisanayo lezinga lokufakwa kwe-transformer lapho liphuma efekthri.Ngaphansi kwezimo ezivamile, akudingekile ukulungisa.Sicela ubheke imiyalelo yokufaka nokusebenza kwesibonisi sokulawula izinga lokushisa kanye nebhokisi lokulawula izinga lokushisa (uma likhona).Ngemva kokuthi isilawuli sezinga lokushisa nesibonisi somswakama silungiswe kahle, qala ngokufaka i-transformer, bese usebenzisa isibonisi sokulawula izinga lokushisa nokuswakama.

3.2 Ngaphambi kokuqalisa ukusebenza, i-transformer kufanele ivalwe izikhathi ezintathu ngaphansi kokungalayishwa ngaphansi kwe-voltage elinganiselwe.

3.3 Ngemuva kokuthi i-no-load ifaneleka izikhathi ezintathu, ingafakwa ekusebenzeni ngomthwalo, futhi umthwalo kufanele ukhuliswe kancane kancane.

3.4 Ngesikhathi sokuvala okungalayishiwe, ngenxa ye-excitation inrush current enkulu, izilungiselelo zokuvikela ezidlulele kanye nezokunqamuka okusheshayo kufanele zihambisane kahle.

3.5 Ukusebenza okugcwele ngokweqile kwe-transformer kufanele kwenziwe ngokuhambisana ne-GB/T17211-1998 (IEC905) "Iziqondiso Zokulayishwa Kwama-Dry-Type Power Transformers", kanye ne-voltmeter, i-ammeter, imitha yamandla kanye nedivayisi yokulinganisa izinga lokushisa kufanele iqashwe ngokucophelela. ukunquma ukuthi kukhona yini okungavamile ku-transformer., ukuze kuthathwe izinyathelo zokuthulula ngesikhathi ukuze kuvinjwe i-transformer ukuthi ingagcwali kakhulu.

3.6 Uma umsindo ongavamile noma i-alamu yokushisa ngokweqile kwenzeka ku-transformer ngesikhathi sokusebenza, kufanele kuqashelwe futhi kuthathwe izinyathelo ezihambisanayo.

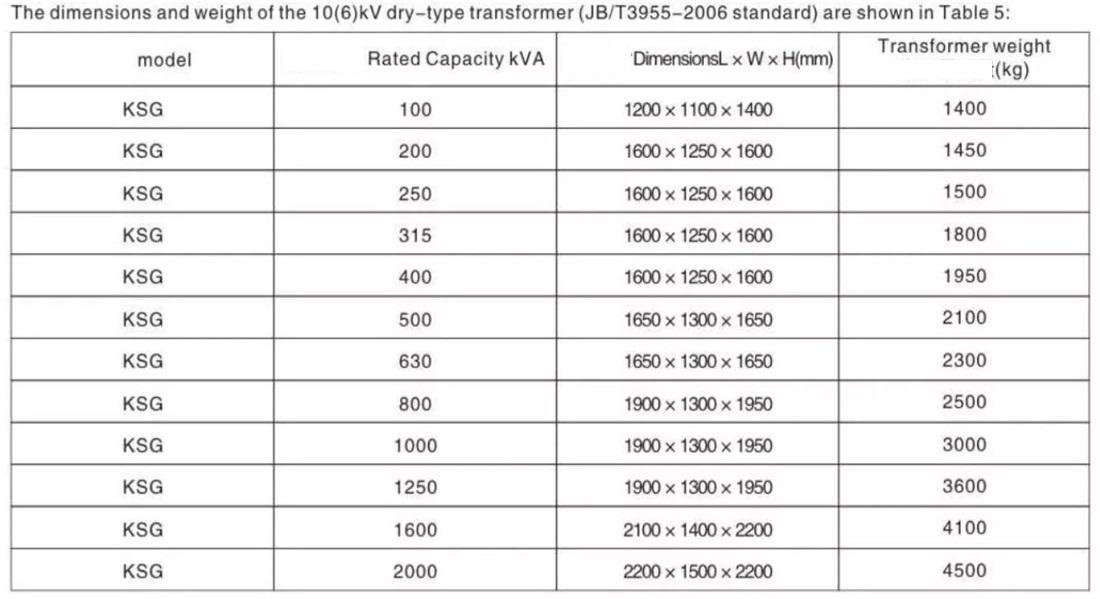

Imininingwane yomkhiqizo

Imikhiqizo shot real

Ikhona leshabhu yokukhiqiza

Ukupakishwa komkhiqizo

Ikesi lesicelo somkhiqizo