I-GTY 1.5-1000mm² 1.8-44mm Amalugi ekhebula ethubhu ehlanganisiwe yethusi

Incazelo Yomkhiqizo

Ekuxhumekeni kokudluliselwa kwamandla kanye namadivayisi wokusabalalisa amandla, ngokuvamile kuyadingeka ukuxhuma izintambo ze-aluminium ezintambo zethusi.Ukuze ugweme ukugqwala kwe-galvanic lapho izintambo zethusi zixhunywe ngokuqondile ezintambo ze-aluminium, amapayipi okuxhuma ithusi-aluminium ngokuvamile asetshenziselwa ukuxhuma.Njengamanje, iningi lamapayipi axhuma i-copper-aluminium emakethe ashiselwe nge-aluminium ekupheleni kanye nokuphela kwethusi.Lolu hlobo lwepayipi lokuxhuma i-copper-aluminium lusebenzisa inani elikhulu lethusi futhi izindleko zokukhiqiza ziphezulu;ngesikhathi esifanayo, ingxenye yenguquko yethusi-aluminium incane, futhi ifakwe emgqeni.Amandla aqinile endaweni ye-copper-aluminium transition azodala umonakalo endaweni yokushisela i-copper-aluminium transition, okuholela ekuphikeleni ngokweqile kanye nokwenyuka kwezinga lokushisa lomkhiqizo ngesikhathi sokusetshenziswa, futhi kujwayele ukuphuka, kuthinte ukusebenza okuvamile kwesistimu yamandla.

Ipayipi elixhumayo lifanele ukuxhumana phakathi kwezintambo eziyindilinga neziyisiyingi ezimise okwefeni kanye nezintambo zamandla kudivayisi yokusabalalisa amandla.Ipayipi yokuxhuma yochungechunge lwe-GT oluvimba uwoyela yenziwe ngenduku yethusi ye-T2, futhi ipayipi yokuxhuma yochungechunge lwe-GT yohlobo lwe-hole yenziwe nge-T2 copper punching.Yenziwe ngochungechunge lwe-GL oluvimba uwoyela uhlobo lwepayipi lokuxhuma, elenziwe ngenduku ye-aluminium ye-L2.Amapayipi axhumayo e-GTL e-copper-aluminium akhiqizwa inqubo yokushisela ngekhwalithi ethembekile.

Izici zomkhiqizo

Ilungele ukuxhunywa kwenguquko yezintambo ezihlukahlukene eziyindilinga kanye nengxenye eyindilinga ye-aluminium alloy kumadivayisi okusabalalisa amandla kanye neziphetho zethusi zemishini kagesi.I-aluminium impahla yi-L3 kanti i-copper yi-T2.Umkhiqizo ukhiqizwa inqubo yokushisela i-friction, enezici zamandla aphezulu we-weld, ukusebenza kahle kukagesi, ukumelana nokugqwala kwe-galvanic, nempilo ende yesevisi.Ingafakwa ezindaweni ezihlukene kanye nama-engeli, okuthuthukisa ukusebenza kahle komsebenzi futhi kunciphise umfutho wabasebenzi.Ngesikhathi esifanayo, inganciphisa ngempumelelo ukungqubuzana okubangelwa i-engeli lapho itheminali nocingo kuxhunyiwe, futhi inciphise izinga lokuvela kwezingozi zemishini.

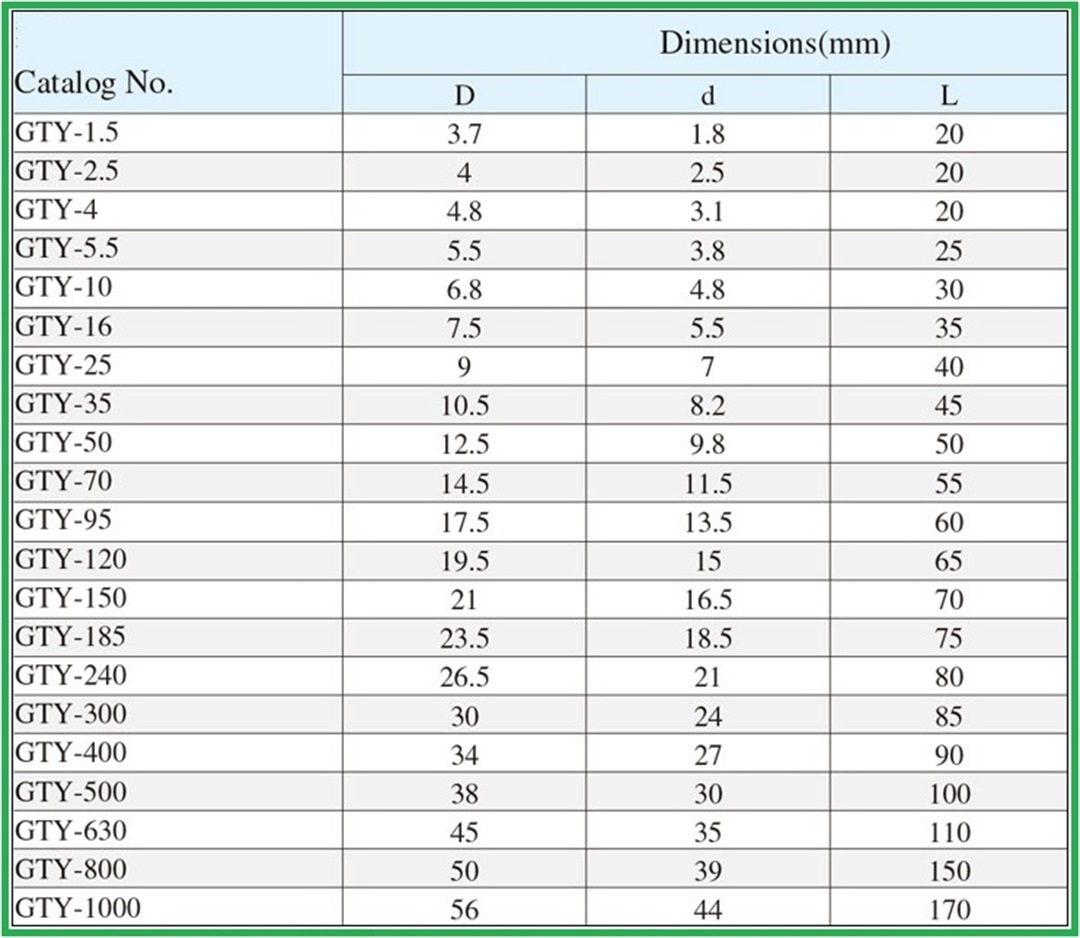

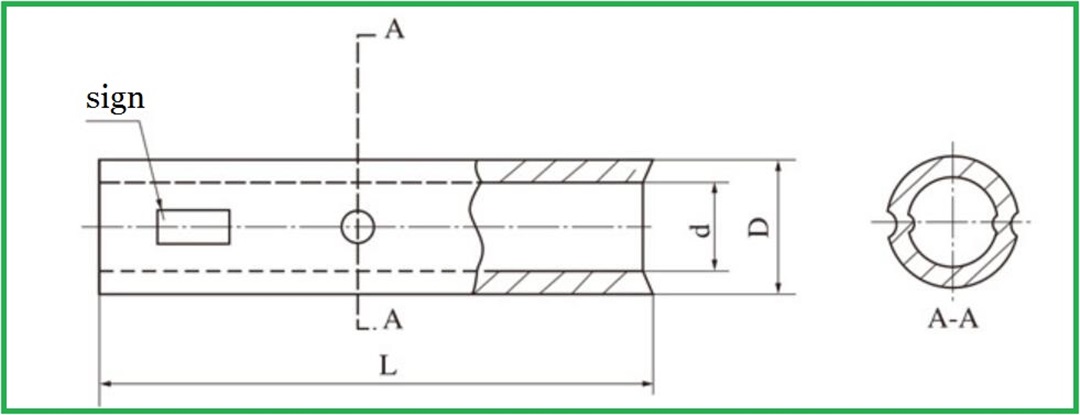

Imininingwane yomkhiqizo

Imikhiqizo shot real

Ikhona leshabhu yokukhiqiza

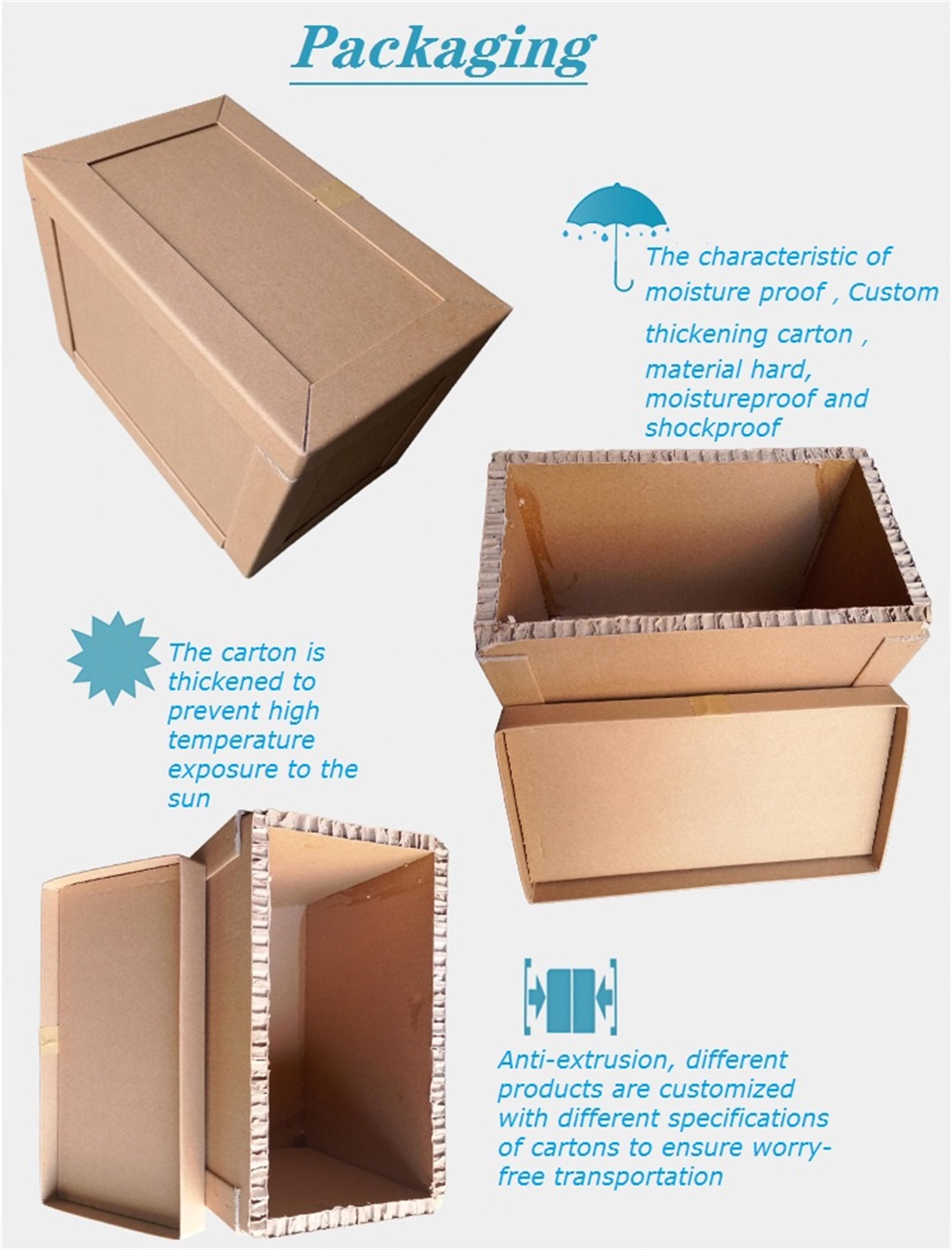

Ukupakishwa komkhiqizo

Ikesi lesicelo somkhiqizo