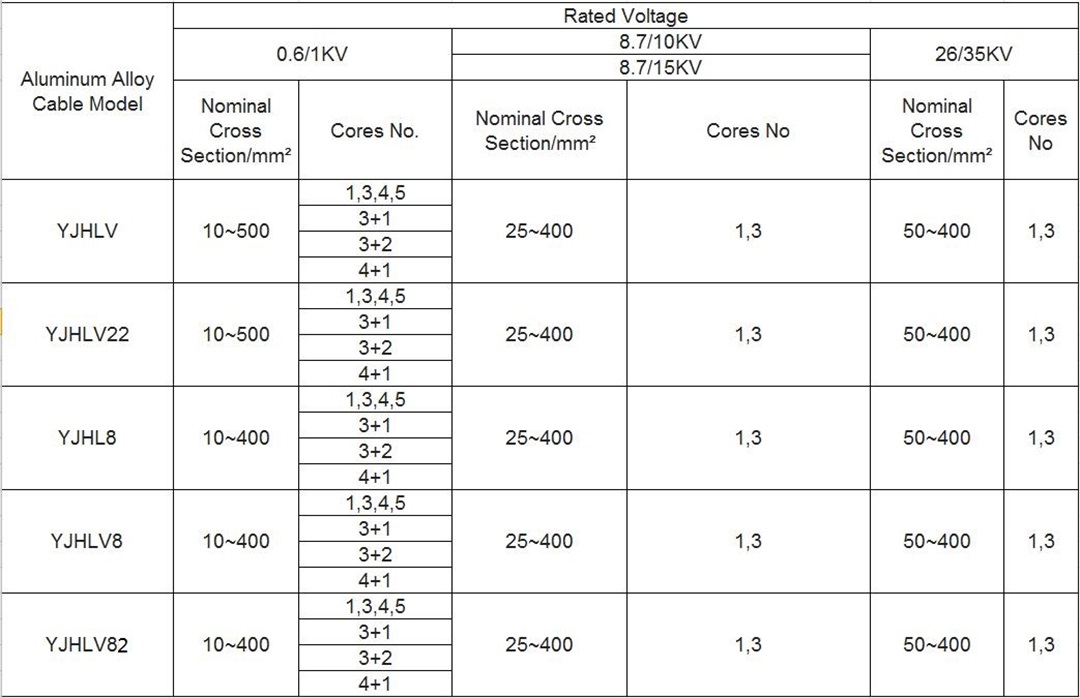

YJHLV(22/82) 0.6/1KV 10-400mm 1-5 core Aluminum Alloy Tape Chain Armoured Power Cable

Product Description

Voltage levels: 0.6/1 kv, 3.6/6 kv, 6/10 kv, 8.7/15 kv, 12/20 kv, 18/30 kv, 21/35 kv and including 26/35 kv

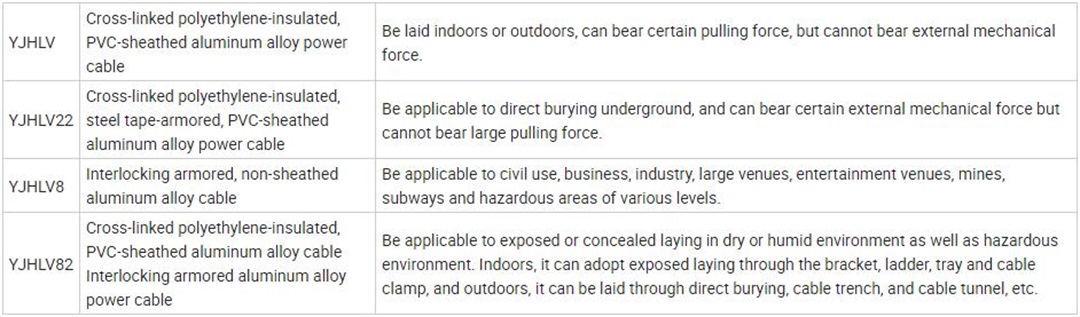

use

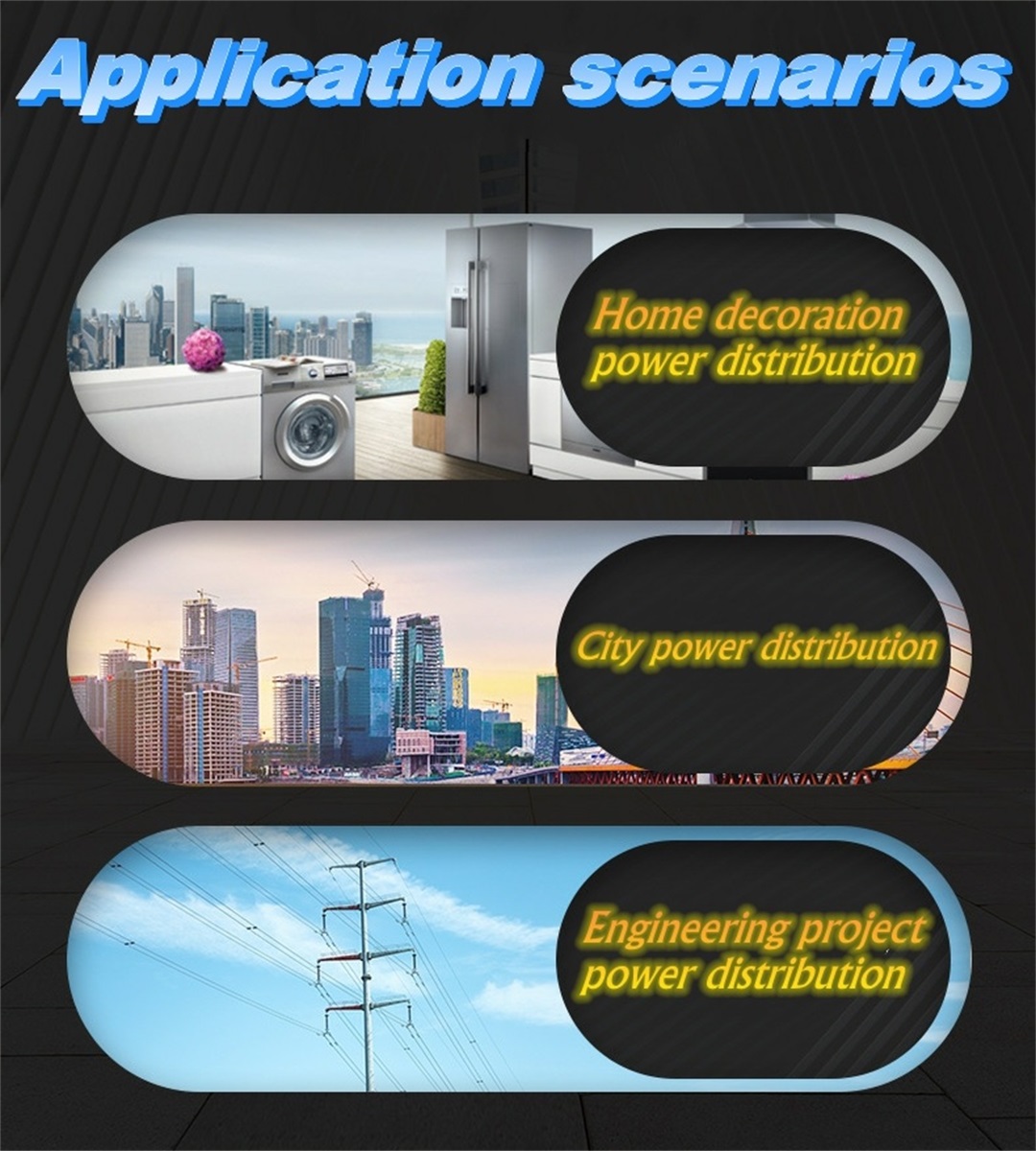

Uses: indoors, tunnels, cable trenches, shafts and other places that can withstand mechanical external forces and certain tension and pressure. It can be applied to power, petrochemical, construction and other systems.

Highly flexible interlocking armored cables can replace wiring pipes, reducing pipeline wiring or bridge costs. This cable is used for laying open or dark wires in a non-humid environment. It can be used in the power supply and distribution system of buildings, such as office buildings, hotels, shopping centers and factories.

Selling point

More excellent economic performance

Aluminum alloy cable is an energy-saving product. Under the premise of achieving the same electrical performance as copper cable, the direct purchase cost of aluminum alloy cable is 20%-30% lower than that of copper cable; because the weight of aluminum alloy cable is only that of copper cable Half, and has good mechanical properties, so the use of alloy cables can reduce transportation and installation costs.

Better mechanical properties

The rebound performance of aluminum alloy cable is 40% lower than that of copper cable, and its flexibility is 25% higher; it has good bending performance, and the laying radius is much smaller than the requirement of copper cable, making it easier to lay and connect the terminals; the special formula and heat treatment process are greatly reduced The creep of the conductor under heat and pressure makes the electrical connection of the alloy cable as stable as the copper cable.

More reliable safety performance

The aluminum alloy cable has been strictly certified by UL in the United States and has been used in the United States, Canada, Mexico and other countries for 40 years without any problems.

Better conductivity

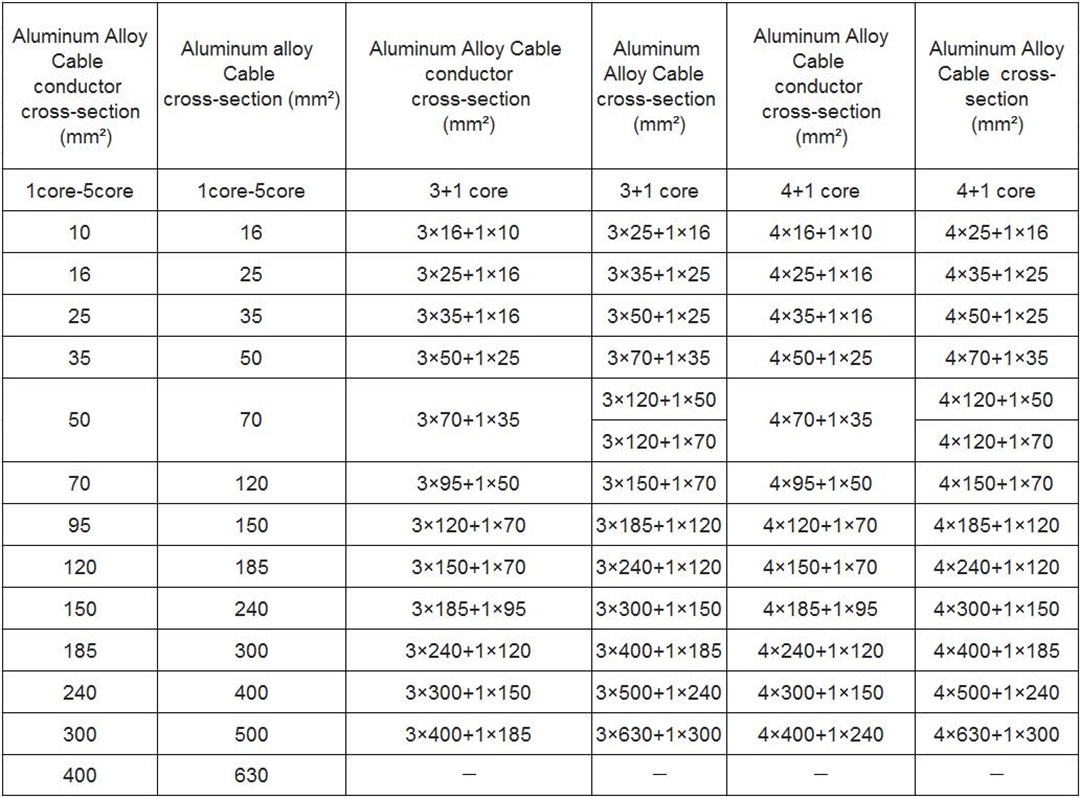

Aluminum alloy cable is a new type of alloy cable that is processed by a special process with unique rare earth elements, copper, iron and other elements on the basis of pure aluminum, and its conductivity is 61% of copper. The hot-extruded wire concentric stranding process is used to increase the cross-section of the alloy conductor by 1.28-1.5 times, so that the electrical properties such as the current carrying capacity and voltage drop of the cable are equivalent to that of the copper cable, and the purpose of "substituting new alloy materials for copper" is achieved.

Excellent anti-corrosion performance.

The aluminum alloy conductor immediately forms a dense oxide layer when it comes in contact with the air. This oxide layer is particularly resistant to various forms of corrosion, so it has the characteristics of withstanding the harshest environment, and is more suitable for use in petrochemical, steel and other severely corroded environments

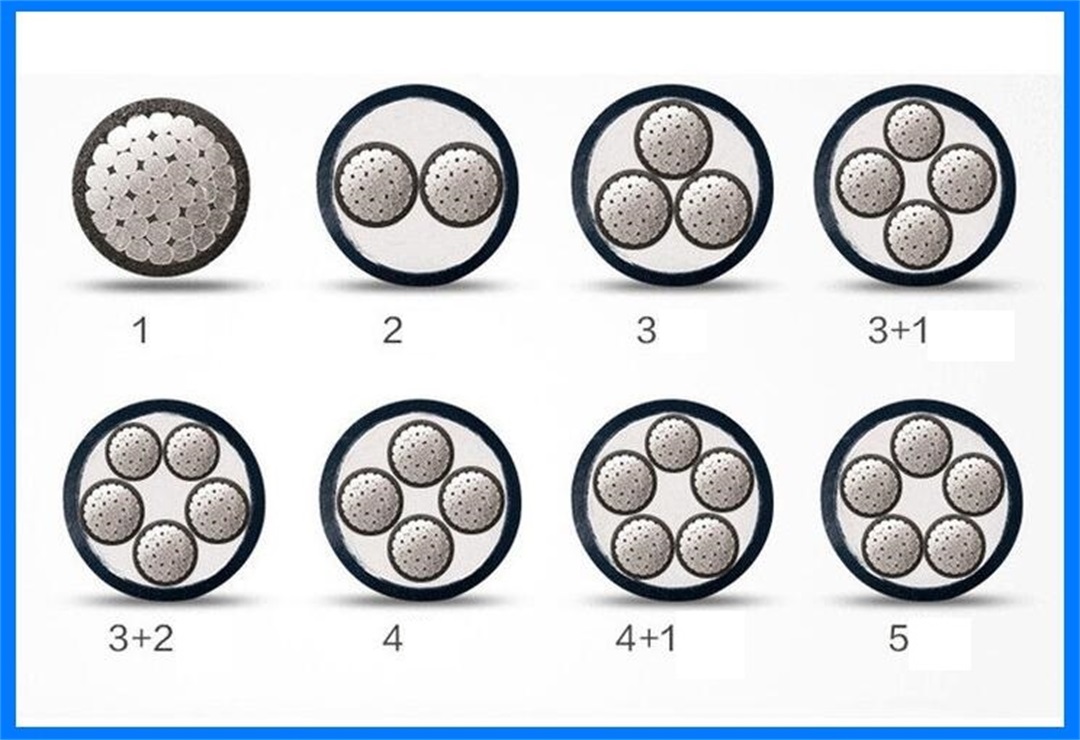

Number of wire cores

Product Instructions for Use

Operating temperature: the maximum long-term operating temperature of the cable conductor is 90°C

Short-circuit temperature: the maximum temperature of the cable conductor does not exceed 250 ℃ during short-circuit (the longest duration does not exceed 5s)

Laying temperature: the ambient temperature when laying the cable should not be lower than 0 ℃

Bending radius: the bending radius of single-core cable is not less than 15 times the outer diameter of the cable, and the bending radius of multi-core cable is not less than 10 times the outer diameter of the cable

Scope of application: It can be laid indoors, in tunnels, cable trenches and pipes, and can also be buried in loose soil. The cable can withstand certain laying traction, but cannot withstand mechanical external force.

Product structure features

◆Price: Under the premise of achieving the same electrical performance, the price of aluminum alloy cables is about 30%~50% lower than that of copper core cables

◆Conductor: Creep resistance, high flexibility, strong extension, low rebound, stable connection

◆Insulation: high temperature resistance, anti-burning, anti-aging, strong and durable, low carbon and environmental protection.

◆Armored layer: superior economic performance, special self-locking form, strong and tough.

Product details

Products real shot

A corner of the production workshop

Product packaging

Product application scenarios