I-NY 185-800mm² Isibambiso soxinzelelo socingo lwe-aluminiyam olukwazi ukumelana nobushushu.

Izithinteli zoxinzelelo zisetyenziswa ikakhulu ukulungisa iikondaktara kunye nezibhengezo zombane kwiintambo zamandla ezingaphezulu okanye kwizitishi, kwaye ziqhagamshelwe kwizithinteli zoxinzelelo ngonxibelelwano lwehardware, okanye ukudibanisa izibambisi zombane kwiinqaba.Ngokwesakhiwo esahlukileyo kunye nendlela yokufakela, yahlulwe yangamacandelo amane: uhlobo lwebholiti, uhlobo loxinzelelo kunye nohlobo lwe-wedge, kunye nohlobo olujijeweyo ngaphambili.

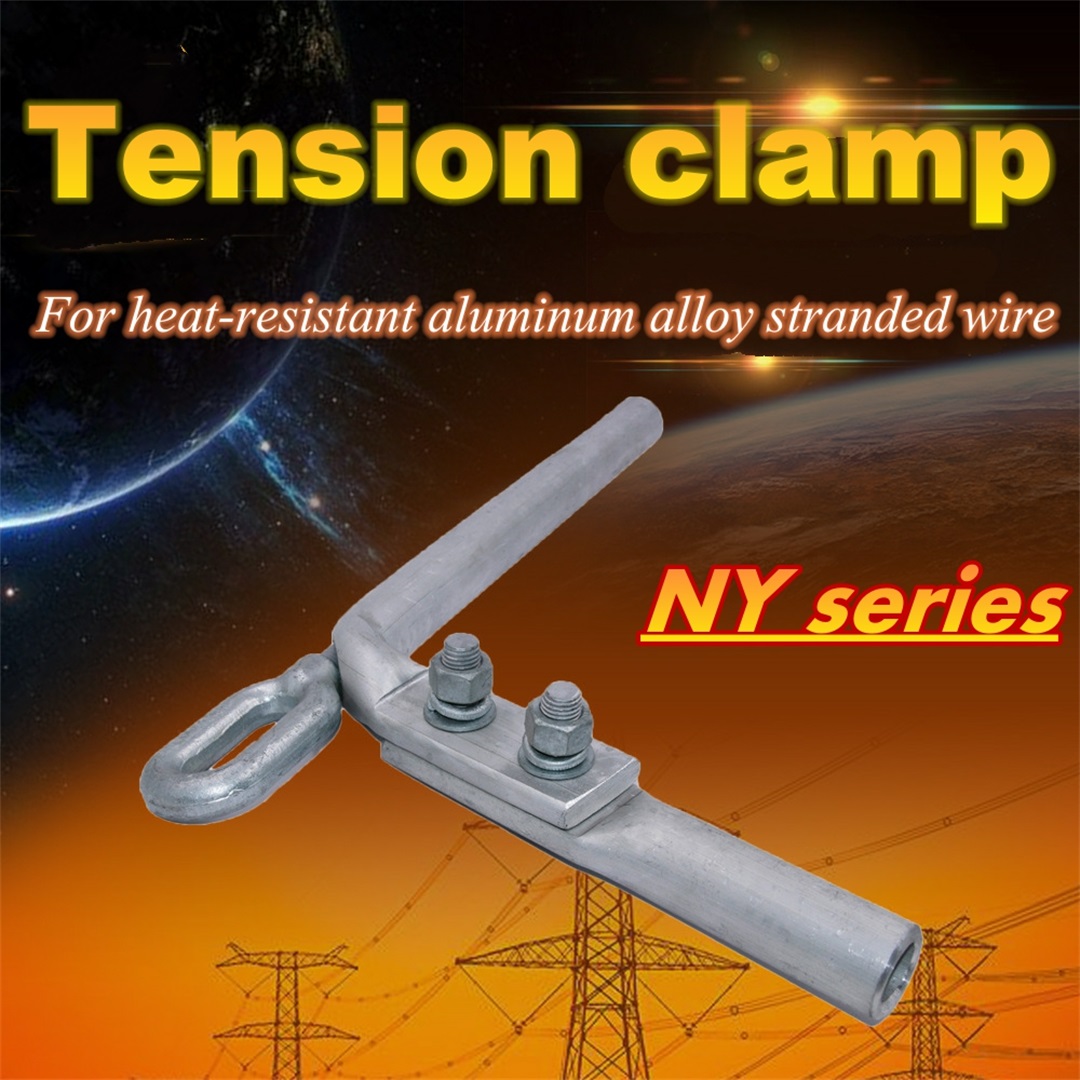

I-NY tension clamp (uhlobo lwe-hydraulic, i-anchor welding yensimbi) isetyenziselwa kakhulu ukulungisa ucingo ukuba luthwale ukunyanzeliswa kocingo, kunye nokuxhoma ucingo kwi-hardware kwintambo yoxinzelelo okanye inqaba.

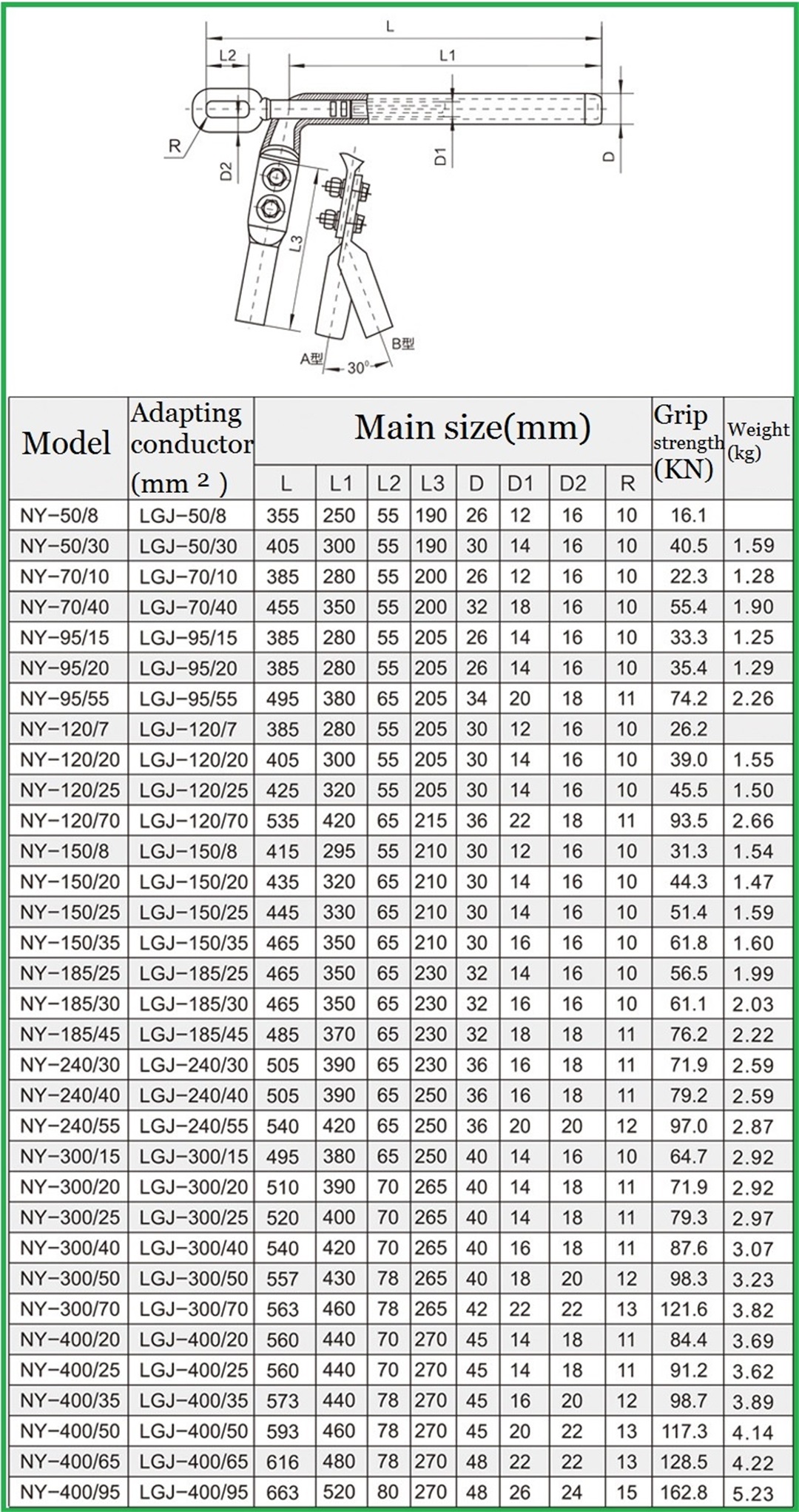

Ingcaciso yeMveliso

Iimpawu zeMveliso kunye nemiba yoFakelo

Iimbonakalo:

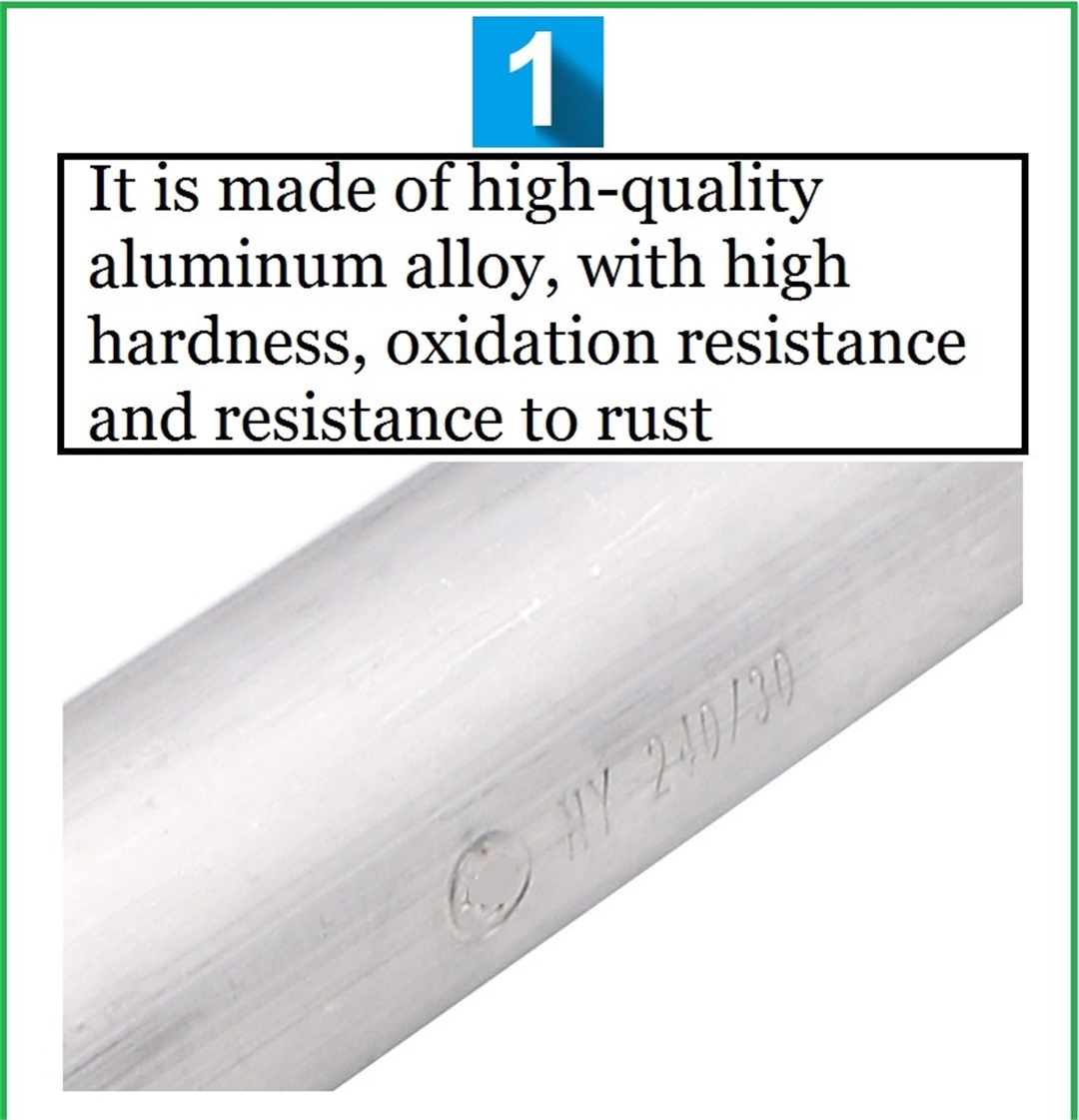

a.Umzimba wekliphu wenziwe ngezinto eziphezulu zentsimbi ye-aluminium.

b.Imbonakalo igudileyo kwaye ubomi benkonzo bude.

c.Kulula ukuyifaka kunye nokusetyenziswa.

d.Akukho lahleko ye-hysteresis, kwaye iyikhabhoni ephantsi, imveliso eqinisekisiweyo yokonga amandla.

Imiba yofakelo:

1. Coca enye incam yocingo oluyi-crimped malunga ne-1m kwaye usebenzise igrisi eqhubayo.

2. Beka ityhubhu ye-aluminiyam ecociweyo (idayamitha engaphandle engu-D) kwisiphelo socingo uze uyitsale ube yi-1m kude nesiphelo socingo.3. Sebenzisa i-vernier caliper okanye umlinganiselo we-tape ukulinganisa ubukhulu be-l 2 ye-tube yangaphambili ye-anchor yensimbi, ukulinganisa ubude bentsimbi yentsimbi ukuba ihlulwe ukusuka ekupheleni kwe-O yocingo ON = l 2 + Δl mm (Δl yi-15mm), yenza uphawu, kwaye uyibophe kumgama we-20mm ukusuka kuphawu Thatha ucingo olusandul 'ukuboshwa P. 4. Vula icandelo le-aluminium strand ekupheleni kwe-O, kwaye ugxininise umgca wentsimbi eveziweyo ngentsimbi. ucingo lokubopha.Emva koko sebenzisa i-cutter (okanye i-aluminiyam i-wire stripper) ukusika imisonto ye-aluminium yangaphandle kunye nephakathi kwindawo yophawu N. ngomnye.Xa kuhluthwa ucingo lwe-aluminium, kunqatshelwe ngokungqongqo ukutyumza intsimbi yentsimbi.)

5. I-Crimp i-anchor yentsimbi

A. Khetha umbhobho wentsimbi die "Cd#" ehambelana nedayamitha yangaphandle d yeankile yentsimbi.Imiyalelo yokuhlohla ye-NY tension clamp kwisikhululo kufuneka iqinisekise ukuba i-engile yediagonal ye-hexagonal die yi-dmm;

B. Cinezela intsimbi Emva kokuba undoqo ucociwe, jikelezisa kwaye uwufake ezantsi kweankile yentsimbi ecaleni kwendlela yokuxinga yombindi wentsimbi, kwaye

isiphelo se-anchor yensimbi sibonisa intsimbi yentsimbi kunye nobude malunga ne-15mm;Ngeli xesha, iingcingo kumacala omabini kufuneka zibe

igcinwe ngokuthe tye kunye ne-anchor yensimbi, kwaye ihambelana ne-axis ye-hydraulic press, ukwenzela ukunciphisa ukugoba okunokwenzeka kombhobho emva kokuxinzelelwa.

D. I-Crimp umbhobho wangaphambili we-anchor yensimbi.Ulwalathiso lwe-crimping luvela kwi-groove yombhobho ukuya emlonyeni wombhobho.Xa usebenzisa uxinzelelo, iimbumba ezimbini ezikufutshane

kufuneka zityebe ubuncinane 5-10mm.Emva koxinzelelo kwihexagon eqhelekileyo, umgama S phakathi kwamacala achaseneyo wehexagon eqhelekileyo kufuneka uqinisekiswe.Ixabiso elivumelekileyo le-S ngu: S=(0.866*0.993d)+0.2.Emva kokubumba, sebenzisa i-caliper eqhelekileyo ukujonga ubungakanani bomgama wecala elichaseneyo emva kokucinezela.(Qaphela: Uxinzelelo lwangempela lwepompo ye-hydraulic akufanele lube ngaphantsi kwe-80Mp, kwaye xa uxinzelelo lufikelela kwixabiso elichaziweyo, kufuneka ligcinwe kwi-3-5s).Qhubeka nomsebenzi we-hydraulic kuphela emva kokuba umgangatho ufezekisiwe.

Iinkcukacha zemveliso

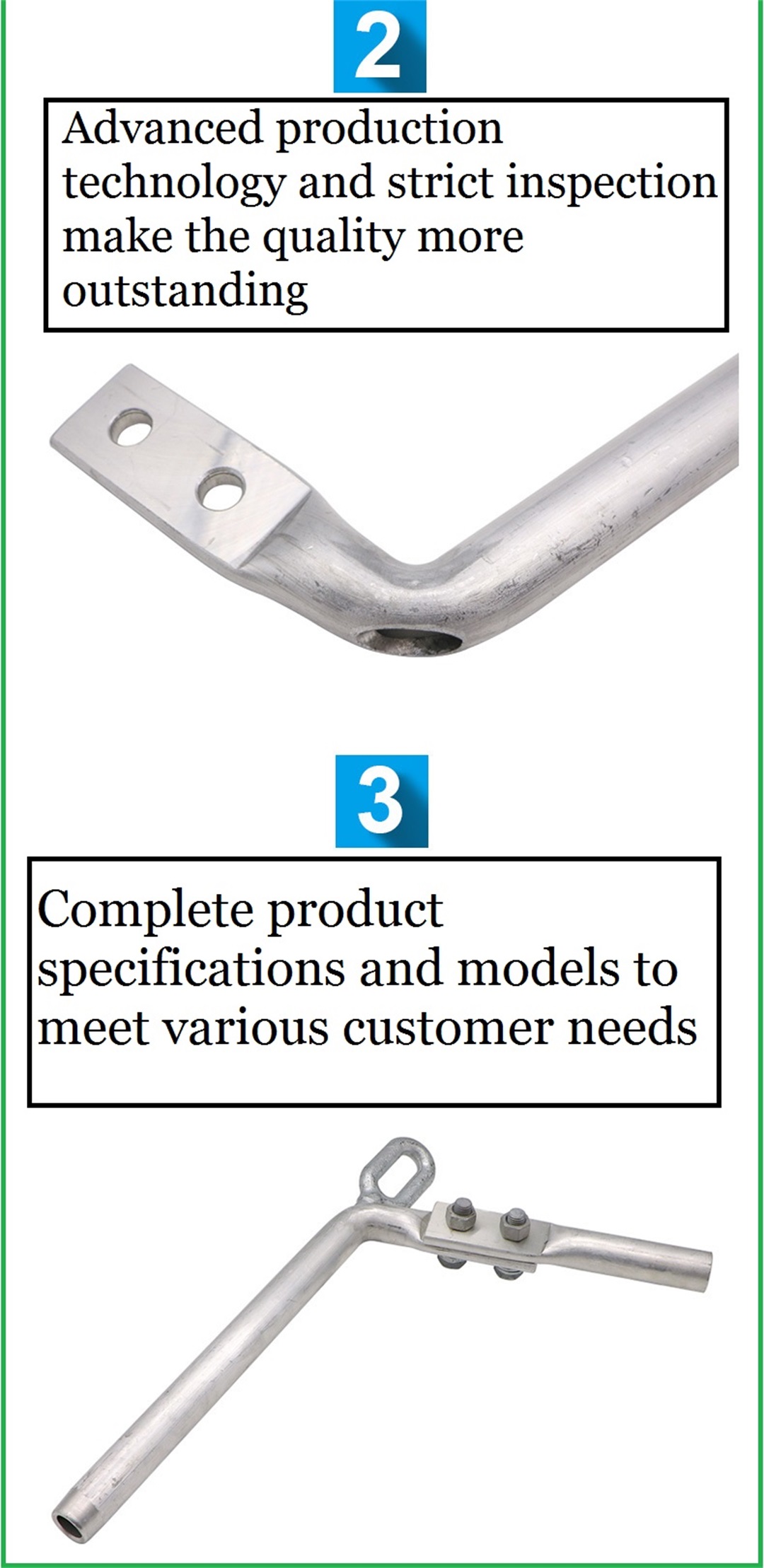

Iimveliso shot real

Ikona yocweyo lwemveliso

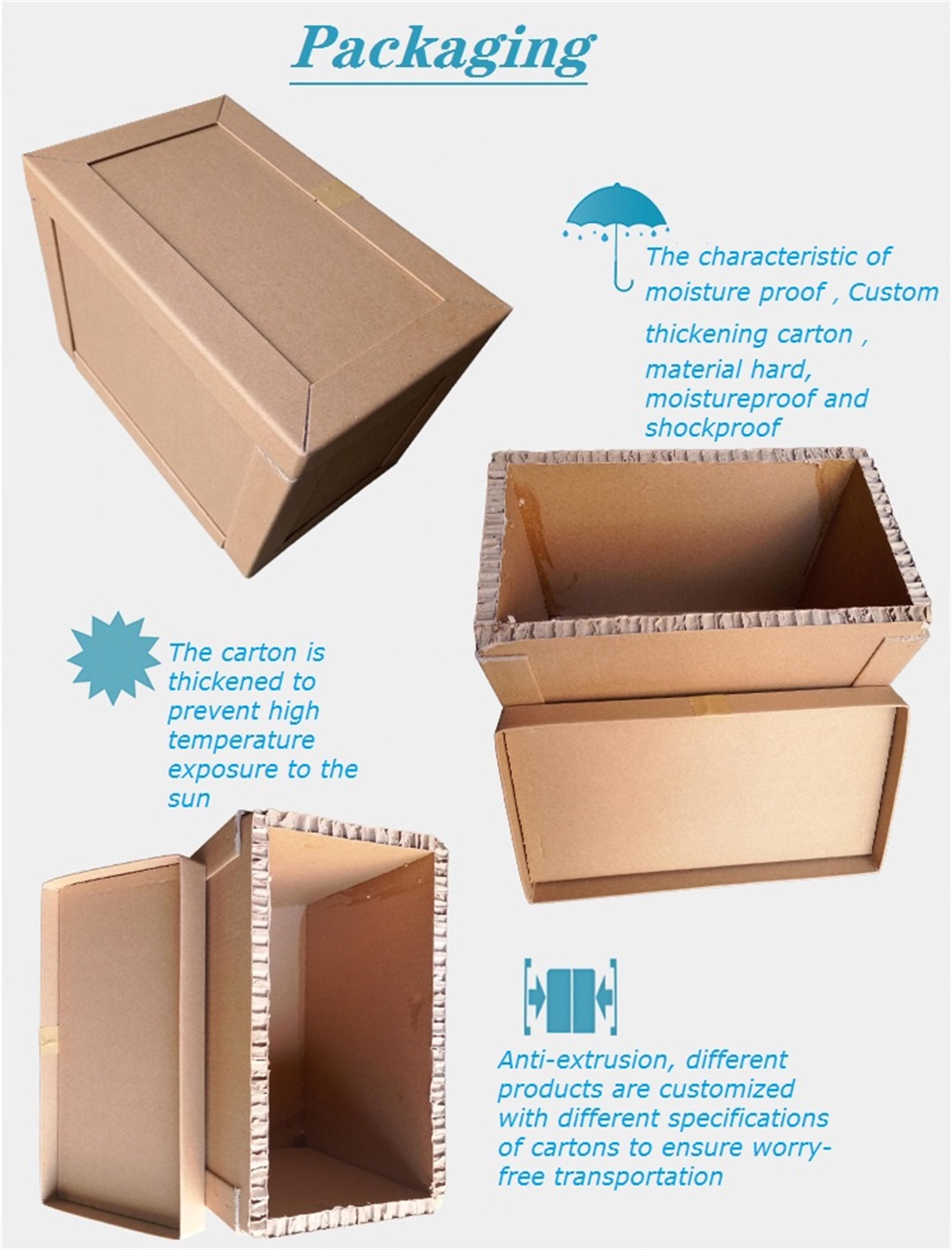

Ukupakishwa kwemveliso

Ityala lesicelo semveliso