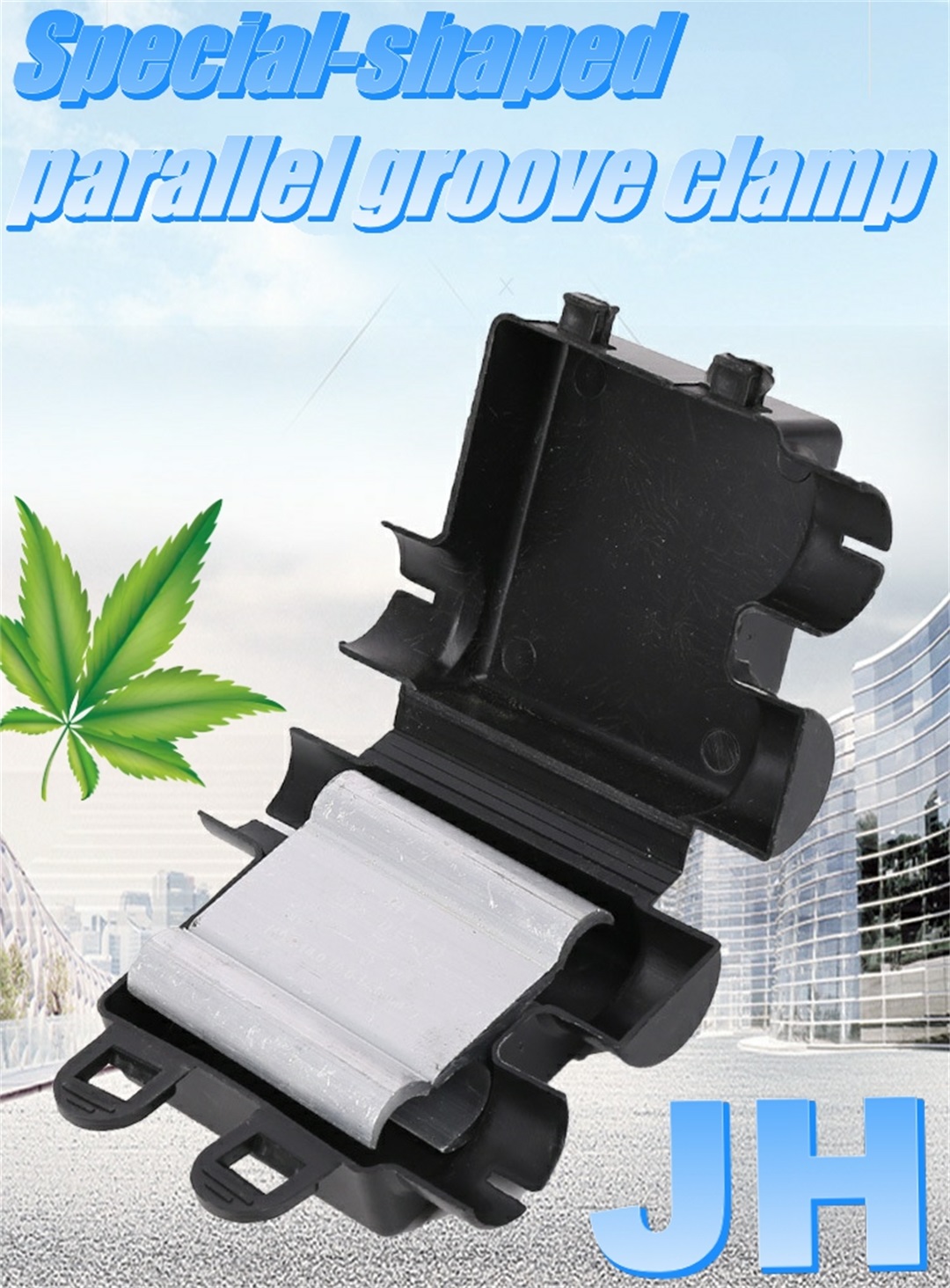

JH 16-240mm² 4.8-22.5mm H-udidi olunxuseneyo locingo lwesebe lohlobo lwentambo yokuqhobosha

Ingcaciso yeMveliso

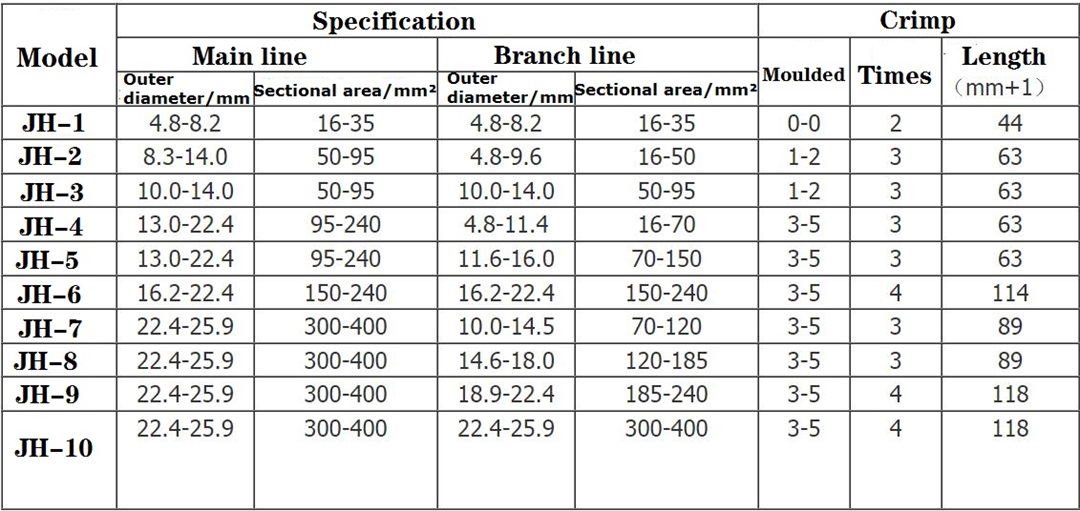

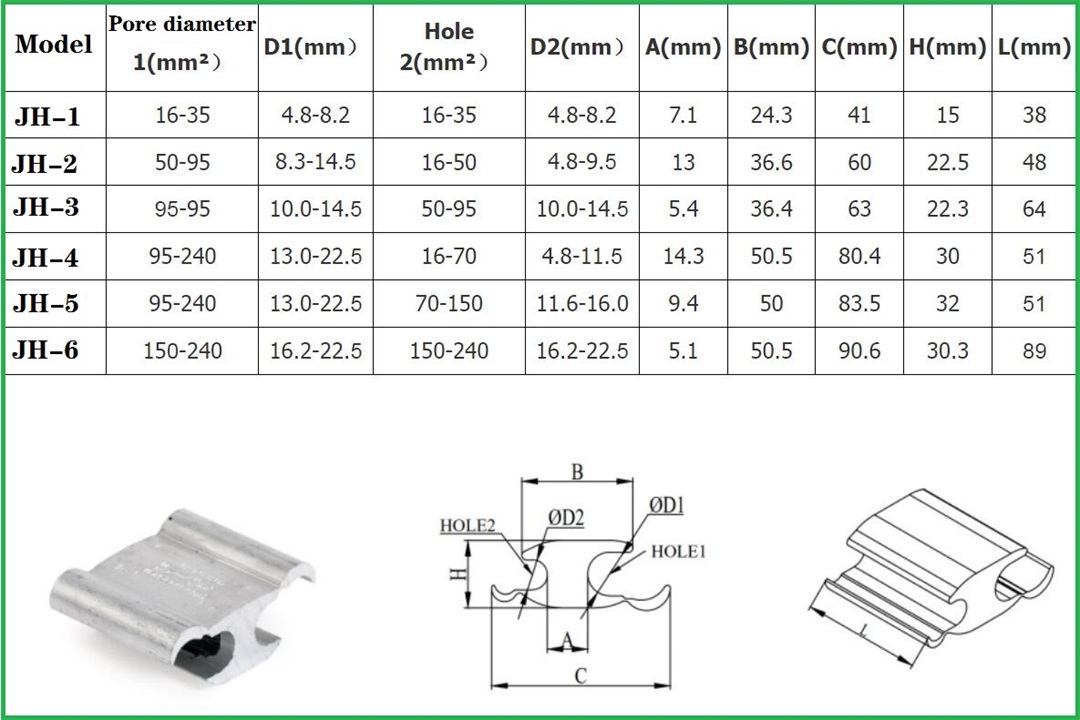

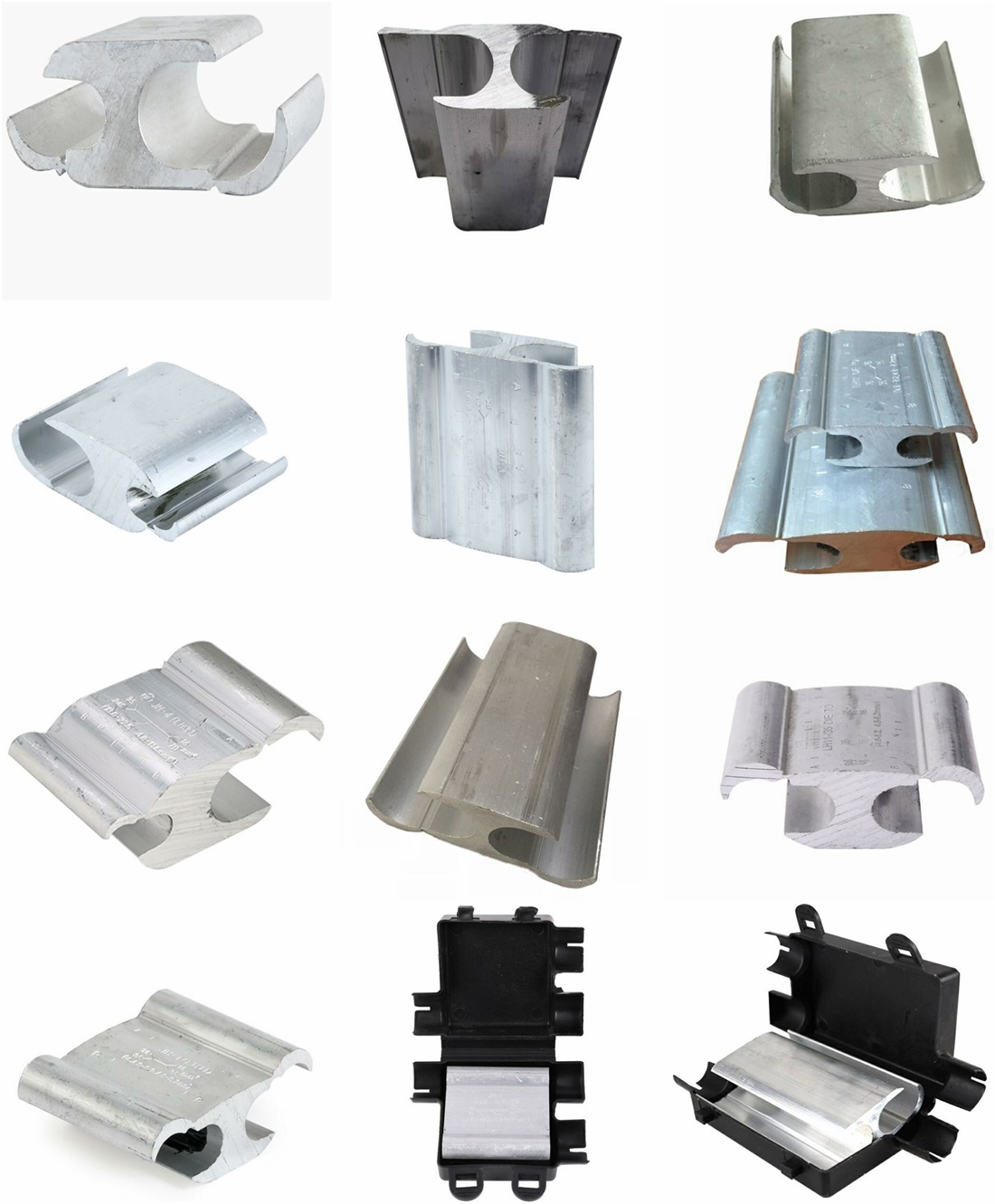

Ikliphu yocingo luhlobo lokufakelwa kwamandla aqhelekileyo, ahlulahlulwe abe ziindidi ezimbini: "i-detachable" kunye ne "crimping (compression)".Iindidi ezinokususwa zibandakanya iikliphu ze-parallel groove, iikliphu ze-wedge, njl.njl. Okwangoku, iibholiti ezahlukeneyo kunye nezibambi zocingo ezikwi-grooved zisasetyenziswa kakhulu, kwaye iingcingo zocingo ezimilise okwe wedge nazo zandiswa ngokukhawuleza.Isici sohlobo olukhutshwayo kukuba lunokuchithwa kwaye lunokusetyenziswa kwakhona.Ininzi yolu hlobo lwee-clamps zenziwe ngeplywood, kwaye uxhulumaniso lugqitywe ngokunyanzeliswa koxinzelelo lweebholiti.Xa udibanisa, indawo yoqhagamshelwano phakathi kwekliphu kunye nocingo incinci, kwaye amandla okuqinisa ibholt nganye ayinakulinganiswa.Ke ngoko, ngokubanzi, ukuchasana kwekliphu ye-bolt kuphezulu kunoko kwekliphu yoxinzelelo.Umzekelo: 240mm² ucingo olunqamlezileyo, ukuxhathisa kwengcingo yi-64.50 microohms, ukuxhathisa kwekliphu yebhawudi yi-50.40 microohms, kwaye uhlobo loxinzelelo lwekliphu yi-24.20 microohms kuphela.Uvavanyo lubonise ukuba incinci i-bolt yoxinzelelo, inkulu ukuchasana.Ke ngoko, iibholiti ezimbini, iibholiti ezintathu kunye nobuncinci iibholiti ezimbini kunye ne-groove clamps zisetyenziswa kuthotho kwi-parallel groove clamps.Oku kungenxa yokuba uxinzelelo lwe-bolt luyanda, indawo yoqhagamshelwano iyanda, kwaye ukuchasana koqhagamshelwano kuyancipha..Enye i-compress type clamp, ebandakanya uhlobo lwe-C, uhlobo lwe-H, njl., olubonakaliswa ngokusetyenziswa kwe-hydraulic pliers ukucinezela i-clamp kunye nentambo ibe yinye, ngenxa yoko, izinga loqhagamshelwano phakathi kwe-clamp. kwaye intambo iyanda ngokungenasiphelo , Ukusebenza kombane kuzinzile kakhulu.Ngokuqhelekileyo, ukuchasana koqhagamshelwano kuphela malunga ne-40% yokumelana nocingo.Ukungalungi kukuba ayinako ukuqhawuka emva kofakelo, kwaye ikliphu ayinakuphinda isetyenziswe.Ii-clamps zohlobo lwe-H zezona zilungele ukusetyenziswa, ngakumbi xa usenza imigca yesebe i-T-connection kunye nemigca yokungena kunye nokungena.

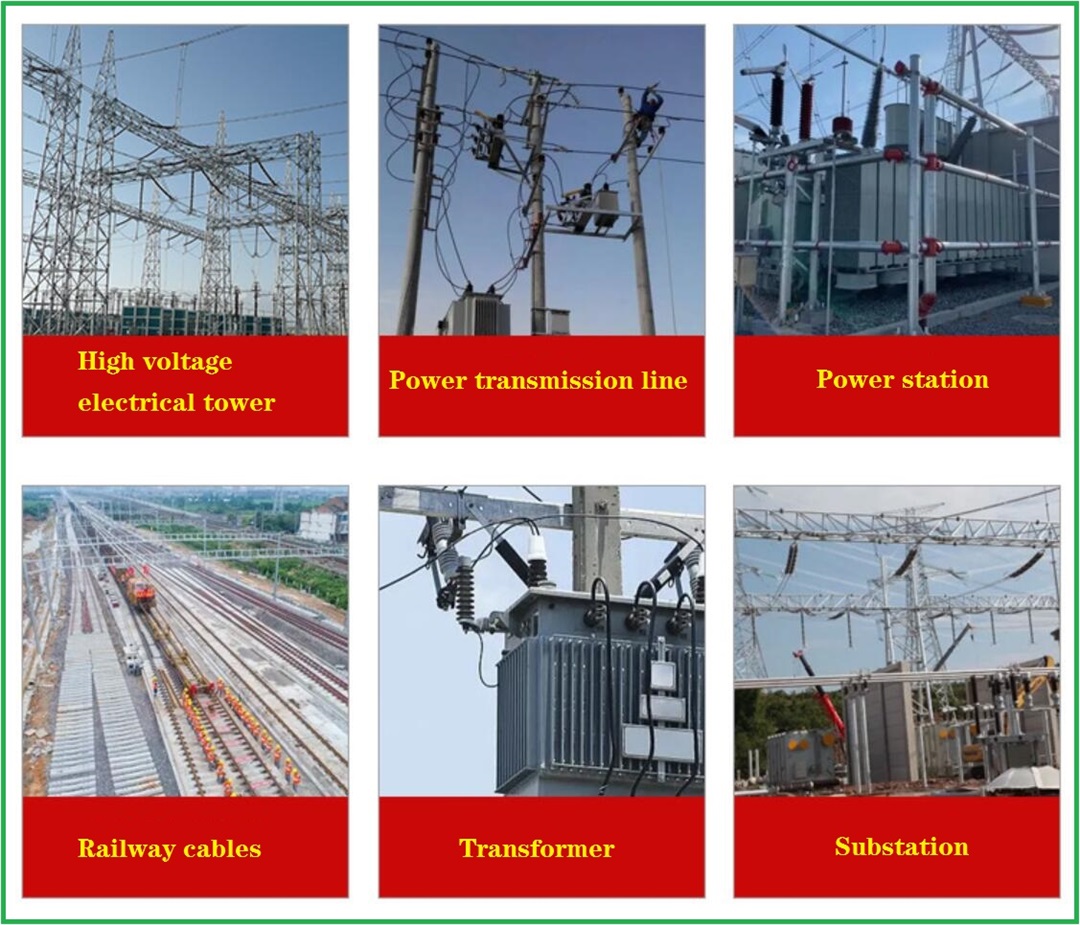

Iikliphu zohlobo lwe-H zilungele ukuqhagamshelwa kweentambo ze-jumper, iingcingo zesebe, iingcingo ezilothe, iingcingo zendlu, kunye neengcingo zokungena ezindlini zombane ophezulu we-voltage kunye ne-low-voltage power line tower.Umkhono we-aluminiyam we-H-uhlobo lwe-aluminiyam yenziwe nge-aluminiyam ecocekileyo, kwaye i-wire hook igcwele i-oyile yokukhusela i-anti-oxidative.Ilungele uxhulumaniso lwe-crimping phakathi komqhubi we-aluminium kunye nomqhubi we-aluminium, kunye nomqhubi we-aluminium kunye nomqhubi wobhedu.okulungileyo, ukuhanjiswa kwangoku okufanayo, ukunyuka kobushushu obuphantsi, ukonga amandla njalo njalo.

Iimpawu zeMveliso kunye noluhlu losetyenziso

Iimpawu zekliphu zodidi lwe-H:

1. Ixabiso lokumelana lincinci, ligcina amandla.

2. Ukunyuka kweqondo lokushisa kuncinci kwaye ukungaphumeleli kuyancipha.

3. Gqibezela iinkcukacha kunye nosetyenziso olubanzi.

4. Umgangatho woxinzelelo kunye nomgangatho uhlangene.

5. Uluhlu lwezinto zokwakha, ezikhuselekileyo kwaye zilungele.

Izinto eziluncedo kwiziqeshana zohlobo lwe-H:

I-Cable clamp yohlobo lwe-H yinto entsha kwaye ephuculweyo ye-cable clamp kumazwe angaphandle.Ineminyaka emininzi yamava aqolileyo ekusebenziseni.Okokuqala, unxibelelwano lukhuselekile kwaye luthembekile.Ekubeni udibaniso oluninzi lwenziwe phakathi kweengcingo ze-aluminium, le nto kanye inzuzo ye-H-clamp.Ikliphu yohlobo lwe-H isekelwe kwi-aluminium, efana nempahla yocingo lwe-aluminium.Uxinzelelo lweetoni ezili-12 lulungile, kwaye ludityaniswe emva kwe-crimping, ngoko ke naxa iqondo lokushisa litshintsha, akuyi kubakho ukudodobala.

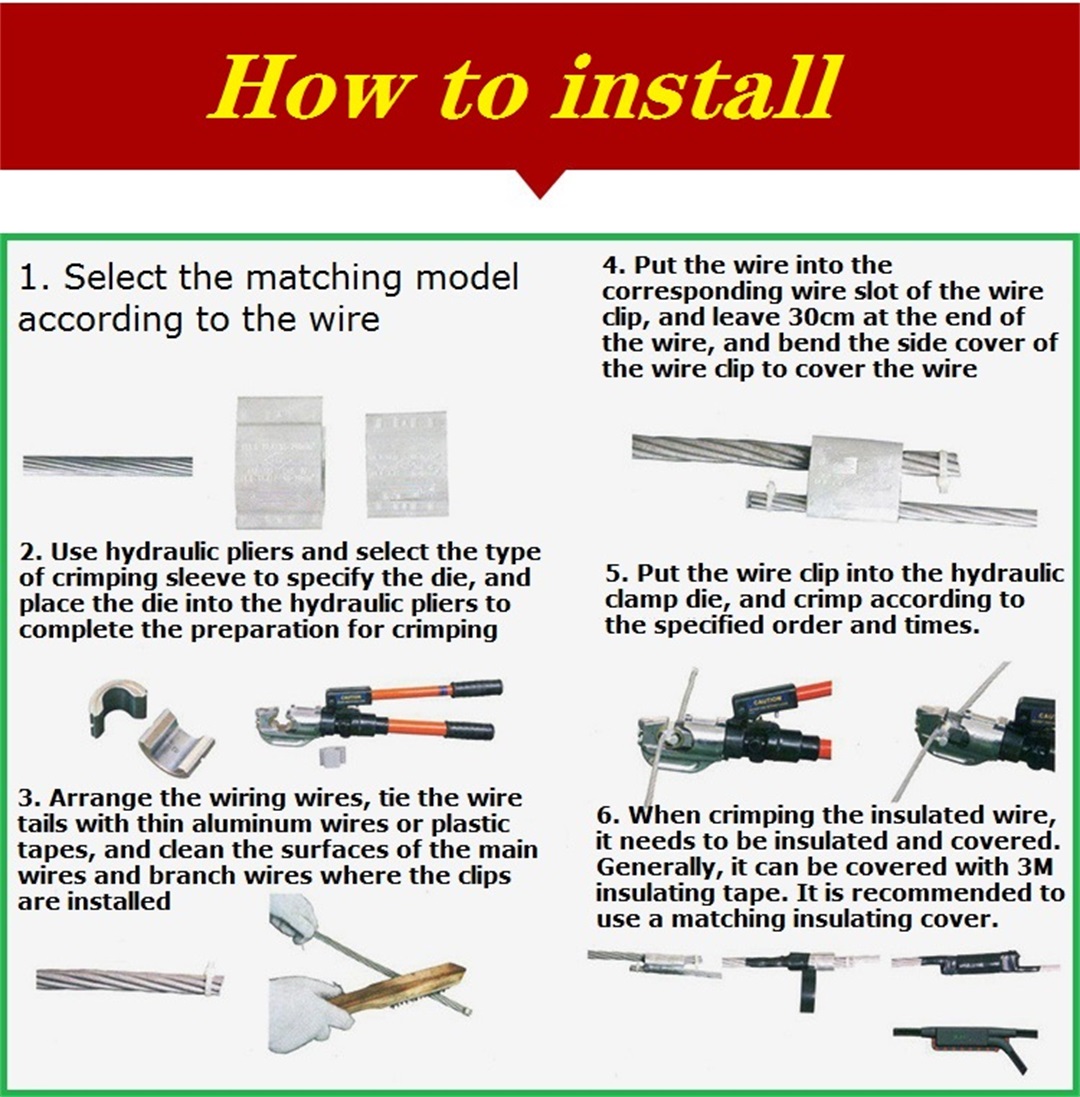

Ukusetyenziswa kwe-H-clamp:

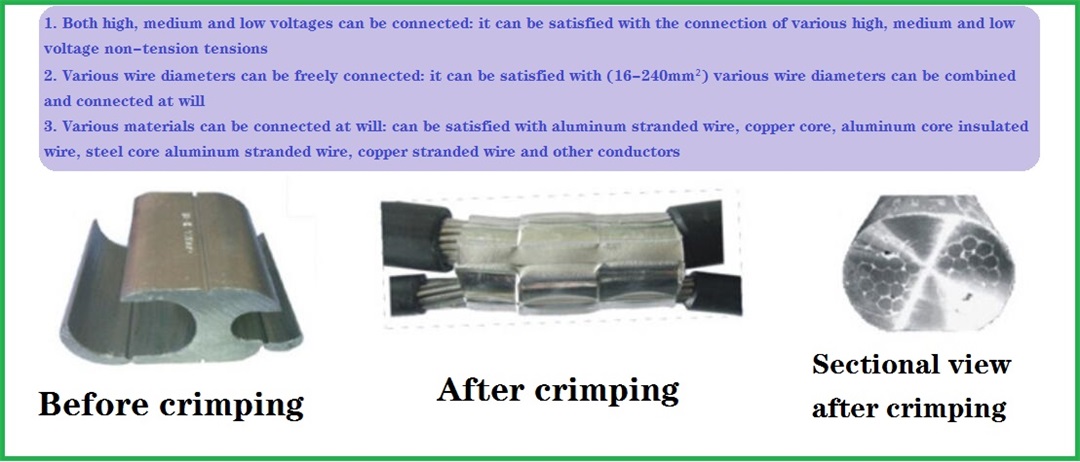

1. Sebenzisa iipliers zehydraulic for crimping, kwaye ufake i-die kunye nesayizi ye-clamp ehambelanayo.

2. Sebenzisa ibhrashi yocingo ukuze usule kancinci isahlulo se-crimped yocingo lwe-aluminium okanye i-steel-cored aluminium intambo ukususa umaleko we-oxide wangaphandle.

3. Faka i-conductor yesibini okanye i-conductor ye-cross-section efanayo xa inqanyuliwe, kwi-B-groove, kwaye ucinezele iifins zecala le-B-groove ngesithupha sakho.

4. Faka eyona nto iphambili kumgca ongu-A uze ucinezele amaphiko ecala lika-A ngobhontsi wakho.

5. Beka iipliyitha ezisebenza ngehydraulic ezifakwe nedayizi kuphawu lokukhuhla ||A||yesibambiso socingo, kwaye enze i-crimping ngokwenani leegridi.

6. Iipliers ze-hydraulic kufuneka zikhuphe ngokupheleleyo ukukhulula uxinzelelo ngexesha lokukhwabanisa ngalunye, kwaye i-crimping igqityiwe.

7. Emva kokuba yonke i-crimping ngokwenani leegridi zigqityiwe, susa i-hydraulic clamp.

8. Ukuba i-insulated wire, sula i-chrome-zinc acid paste eveziweyo, kwaye uyibophe nge-high-voltage insulating self-dissolving tape ukugqiba ukugquma.Emva koko i-tape ye-UV-proof ihlanganiswe ngokufanelekileyo, kwaye yonke inkqubo igqityiwe.Okanye gquma ikliphu yocingo nge-insulating cover, qinisa i-clasp, kwaye usonge i-outlet nge-high-voltage insulating self-dissolving tape ukugqiba ukugquma.

Umgangatho wokuhlolwa kwemveliso

1. Uvavanyo lwe-tensile

Umgangatho: IEEE IEEE Icandelo 5.2.1 STD837-1989 NEMA IEEE Icandelo 2.7, STD3-22-1972

Iconductor cross section Ubuncinci boxinzelelo (KG)

13-54 136

67-107 227

127-253 454

Umgangatho we-GB / T 2317-2008 kuphela i-10% enkulu kuneyona nto iphezulu yokuqhawula ucingo, kwaye imigangatho ye-TEEE kunye ne-NEMA iphindwe ngamaxesha amaninzi kunomgangatho we-GB.

2. Uvavanyo lokuchasa

Umgangatho: icandelo le-NEMA2.6, i-STD3-22-1972, i-GB/T 2317-2008 Ukuchasana kwekliphu ye-crimped akuyi kuba mkhulu kuneengcingo ezimbini, kwaye i-110% yokuchasana iya kuthathwa njengefanelekileyo.

3. Uvavanyo lokunyuka kobushushu:

Umgangatho: ICandelo le-NEMA2.5.2, STD5-28-1981, GB2317-2000 Ixabiso lokunyuka kweqondo lobushushu lekliphu ye-self-crimped wire clip ayiyi kuba nkulu kunelona xabiso liphezulu lokunyuka kweqondo leengcingo ezimbini.(Xa crimping wire diameters ezahlukeneyo, iqondo lobushushu kwindawo crimping aliyi kuba ngaphantsi kweqondo lobushushu intambo encinane cross-icandelo) GB/T 2317-2008 kuphela ichaza ixabiso lobushushu cross-icandelo lohlobo olufanayo ucingo, kwaye akukho mlinganiso wexabiso lobushushu bocingo olukhethekileyo.

Iinzuzo zemveliso kunye nemiyalelo yokufakela

Amanqaku oFakelo:

1. Jonga uhlobo lwe-wiring, idiameter ye-wire kunye ne-cross-section, kwaye ukhethe i-H-type crimping clamp efanelekileyo.

2. Khumbula ukukhetha izixhobo ezifanelekileyo zokukrazula kunye ne-crimping molds, kunye neengxenye ze-wire crimping kufuneka zihlanjululwe nge-brush yocingo ngaphambi kokuqhawula.

3. Hlela iingcingo ukuze ugweme ukugoba, ukugoba, umonakalo, njl. Emva kokulungiswa komsila wocingo, sebenzisa i-clinker tape ukuyiqinisa.

4. Beka uhlobo lwe-crimping clamp ** i-crimping die kwisixhobo se-crimping.

5. Faka ucingo kwi-hook efanelekileyo ye-H-type crimping clip, shiya i-20-30mm yocingo olungaphandle lwekliphu, kwaye ugobe ama-side covers kumacala omabini ekliphu ye-H-type crimping ukuvala ucingo.Kufuneka kuthathelwe ingqalelo ukuba ucingo lobhedu lungaphantsi kocingo lwe-aluminiyam emva kokukrazula.

6. Sebenzisa isixhobo se-crimping, ulungelelanise isalathiso, kwaye ucinezele imiyalelo yenkqubo ye-crimping kwibhokisi yangaphandle ngokulandelelana ukusuka kumbindi ukuya kumacala amabini, kunye ne-crimp ngokulandelelana kwe-crimping engcono kunye nenani lamaxesha okukhwabanisa.Ukuba kufuneka ihlanjululwe kathathu okanye ngaphezulu, kufuneka igqitywe ukusuka phakathi ukuya kwiziphelo ezimbini ngokulandelanayo, kwaye i-crimping yenziwa ukusuka kwesobunxele ukuya kwesokudla ukuya ekupheleni ngokulandelelana.

7. Zijonge ngeliso lengqondo iziphumo zecrimping.

8. Emva kokuba ucingo lwe-insulation crimped, kusafuneka lugqunywe nge-tape ye-insulating.

Ukuthelekiswa kwe-H-type crimp clamps kunye neeclamp zendabuko:

1. Ubungakanani besicelo:

Abaqhubi abanokugwetyelwa: Cu-Al, Al-Al, Cu-Cu.

Inokukhutshelwa iingcingo ezinobubanzi obufanayo kunye nobubanzi obuhlukeneyo.

Idayamitha yocingo ayilungelelaniswanga, ingasetyenziswa kwakhona.

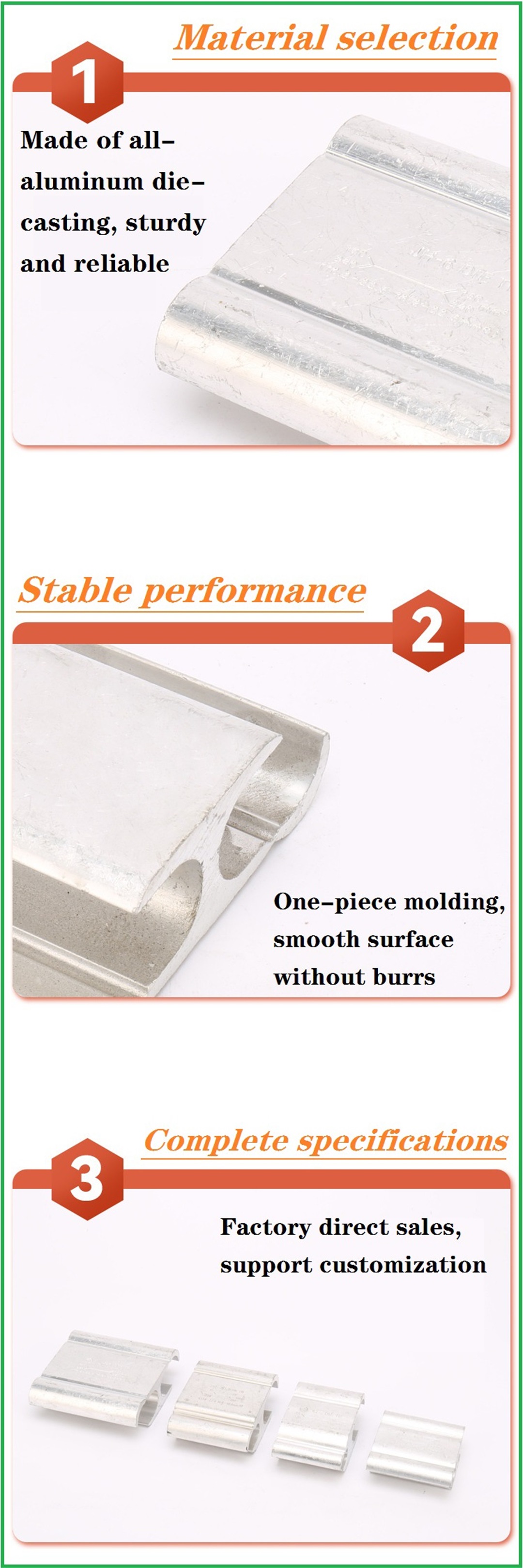

2. Uyilo lwezinto eziphathekayo kunye nolwakhiwo

Ukubumba konke-kwinye kunye nokugubungela okubanzi kwemigca eyahlukeneyo.

Ukuhanjiswa kakuhle kombane, ukuhanjiswa kwangoku okufanayo kunye nokunyuka kobushushu obuphantsi.

Akukho zingxaki zomhlwa.

3. Ulwakhiwo:

Ubunzima bokukhanya (umlinganiselo wobunzima be-H-type clamps ukuya kwi-parallel groove clamps = 1: 8.836).

Ukuchazwa okuncinci, kulula ukuthwala, ukunciphisa ubunzima bomsebenzi wabasebenzi bokwakha.

Ixesha elincinane lokwakha kunye nomsebenzi ophilayo ofanelekileyo.

Umgangatho wokwakha (i-hydraulic clamp).

Akukho mfuneko yokusebenzisa ioli yokukhusela i-anti-oxidative.

4. Iinzuzo:

Iikliphu ze-aluminium zohlobo lwe-H zifuna kuphela iinkcukacha ezi-6, ezinokuhlangabezana nokusetyenziswa kwe-crimping yazo zonke i-aluminium kunye neengcingo zobhedu ukusuka kwi-16 ukuya kwi-240mm2.

Thintela iingozi zokumka kombane ezibangelwa kukuqhawuka kweentambo zombane, nokunciphisa ilahleko “yobonelelo lwamandla amancinane” ombane.

Ukucaciswa kwesicelo kwenziwa lula, kwaye ukulungiswa kwezinto ze-hardware kukulungele.

Nciphisa ilahleko yamandla kumgca.

Ukunciphisa iindleko zokusebenza kunye nokugcinwa.

Ubomi obude kunye nokuqina okulungileyo.

Iinkcukacha zemveliso

Iimveliso shot real

Ikona yocweyo lwemveliso

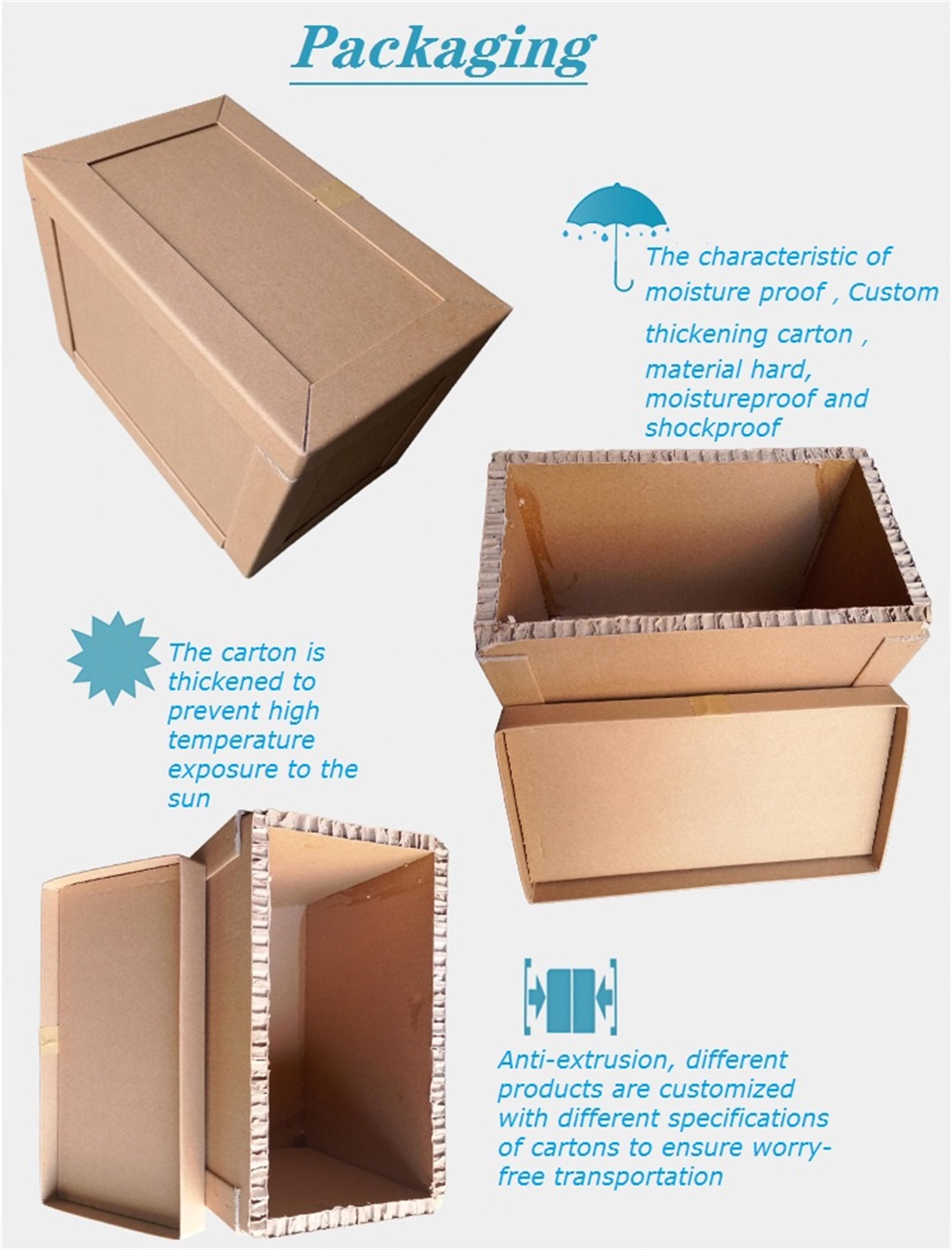

Ukupakishwa kwemveliso

Ityala lesicelo semveliso