I-GTY 1.5-1000mm² 1.8-44mm yobhedu olunkonkxiweyo oludibanisa iilugi zeentambo zetyhubhu

Ingcaciso yeMveliso

Kuxhulumaniso lokuhanjiswa kwamandla kunye nezixhobo zokuhambisa amandla, kudla ngokuyimfuneko ukudibanisa iintambo ze-aluminium kwiintambo zobhedu.Ukuze ugweme i-galvanic corrosion xa iintambo zobhedu zixhunywe ngokuthe ngqo kwiintambo ze-aluminium, iipayipi zokudibanisa i-copper-aluminium zihlala zisetyenziselwa ukudibanisa.Okwangoku, ininzi yobhedu-aluminiyam yokudibanisa imibhobho kwiimarike idityaniswe kunye nokuphela kwe-aluminium kunye nobhedu.Olu hlobo lombhobho wokudibanisa ubhedu-aluminium lusebenzisa inani elikhulu lobhedu kwaye ixabiso lokuvelisa liphezulu;ngelo xesha, icandelo lenguqu yobhedu-aluminium lincinci, kwaye lifakwe kumgca.I-tensile force kwi-copper-aluminium transition surface iya kubangela umonakalo kwi-welding ye-aluminium ye-copper-aluminiyam, okubangela ukuchasana okugqithisileyo kunye nokunyuka kobushushu bemveliso ngexesha lokusetyenziswa, kunye nokuthanda ukuphuka, okuchaphazela ukusebenza okuqhelekileyo kwenkqubo yamandla.

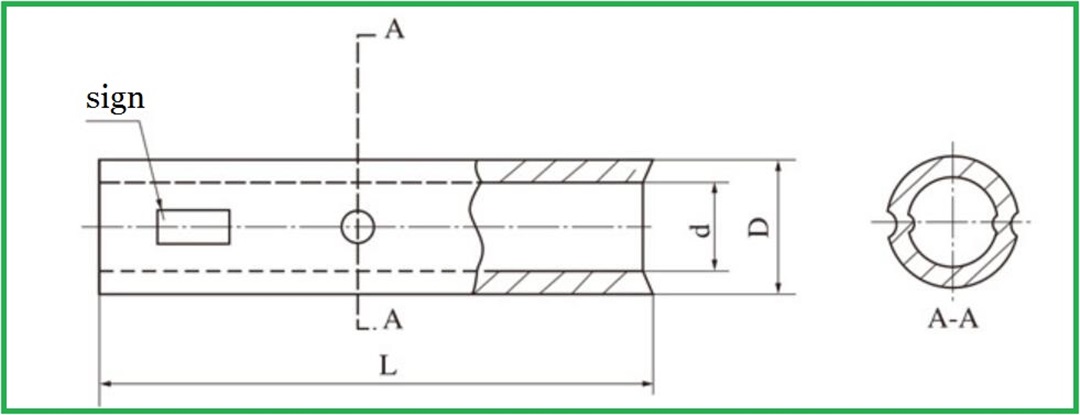

Umbhobho wokudibanisa ufanelekile ukudibanisa phakathi kweengcingo zesetyhula kunye ne-semi-circular fan-shaped kunye neentambo zamandla kwisixhobo sokuhambisa amandla.Uluhlu lwe-GT lwe-oyile yokuthintela uhlobo lombhobho wokudibanisa lwenziwe ngentonga yobhedu lwe-T2, kunye nochungechunge lwe-GT nge-hole yokudibanisa umbhobho we-T2 we-punching yobhedu.Yenziwe nge-GL yochungechunge lwe-oyile yokuthintela uhlobo lombhobho wokudibanisa, owenziwe nge-L2 intonga ye-aluminium.Uluhlu lwe-GTL lwemibhobho yobhedu-aluminiyam yokudibanisa iveliswa yinkqubo ye-welding ye-friction enomgangatho othembekileyo.

Iimpawu zemveliso

Ilungele ukudityaniswa kwenguqu yeentambo ezahlukeneyo ze-aluminium ezijikelezayo kunye ne-semi-circular kwizixhobo zokuhambisa amandla kunye neziphelo zobhedu zezixhobo zombane.Izinto ze-aluminium yi-L3 kunye nezinto zobhedu yi-T2.Imveliso yenziwa yinkqubo ye-friction welding, eneempawu zamandla aphezulu e-weld, ukusebenza kakuhle kombane, ukuchasana ne-galvanic corrosion, kunye nobomi benkonzo ende.Inokufakwa kwiindawo ezahlukeneyo kunye nee-angles, eziphucula ukusebenza kakuhle kunye nokunciphisa amandla omsebenzi.Kwangaxeshanye, inokunciphisa ngokufanelekileyo ukungqubana okubangelwa yi-engile xa i-terminal kunye nocingo zidityanisiwe, kunye nokunciphisa izinga lokwenzeka kweengozi zezixhobo.

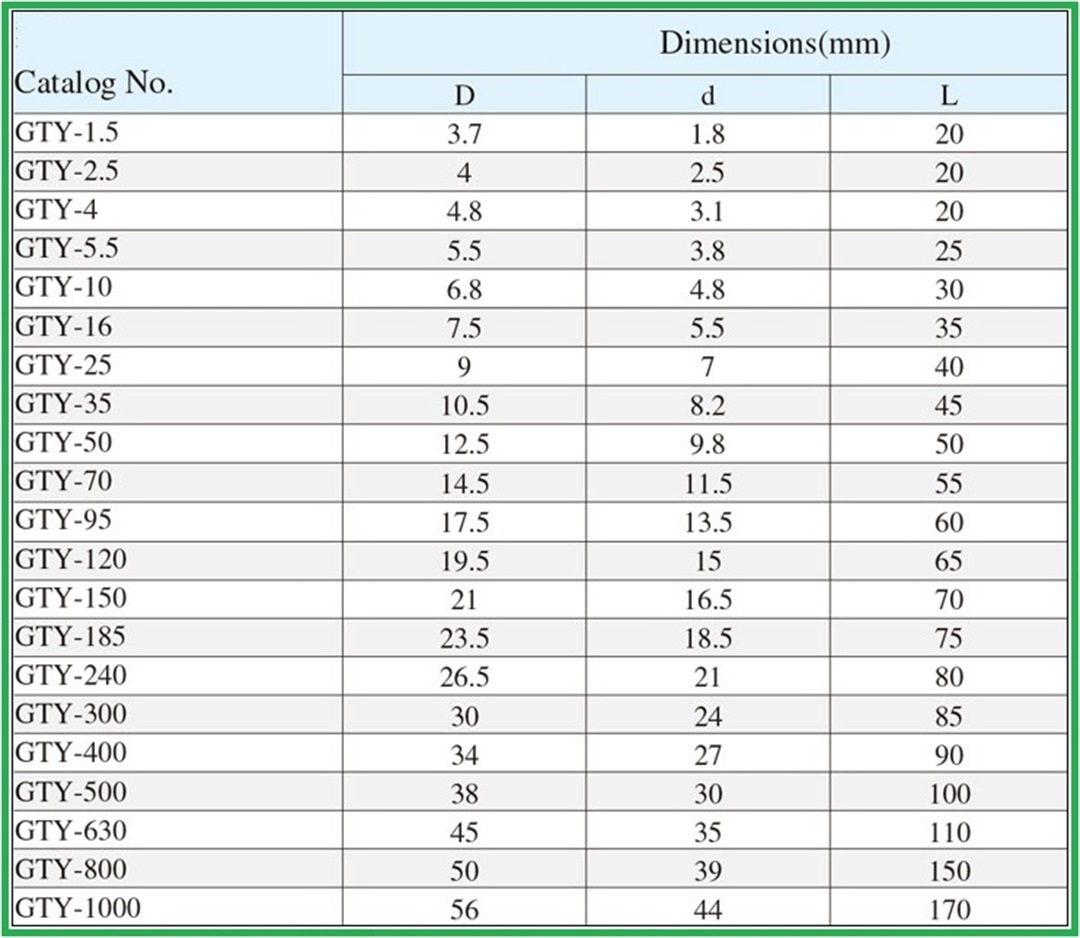

Iinkcukacha zemveliso

Iimveliso shot real

Ikona yocweyo lwemveliso

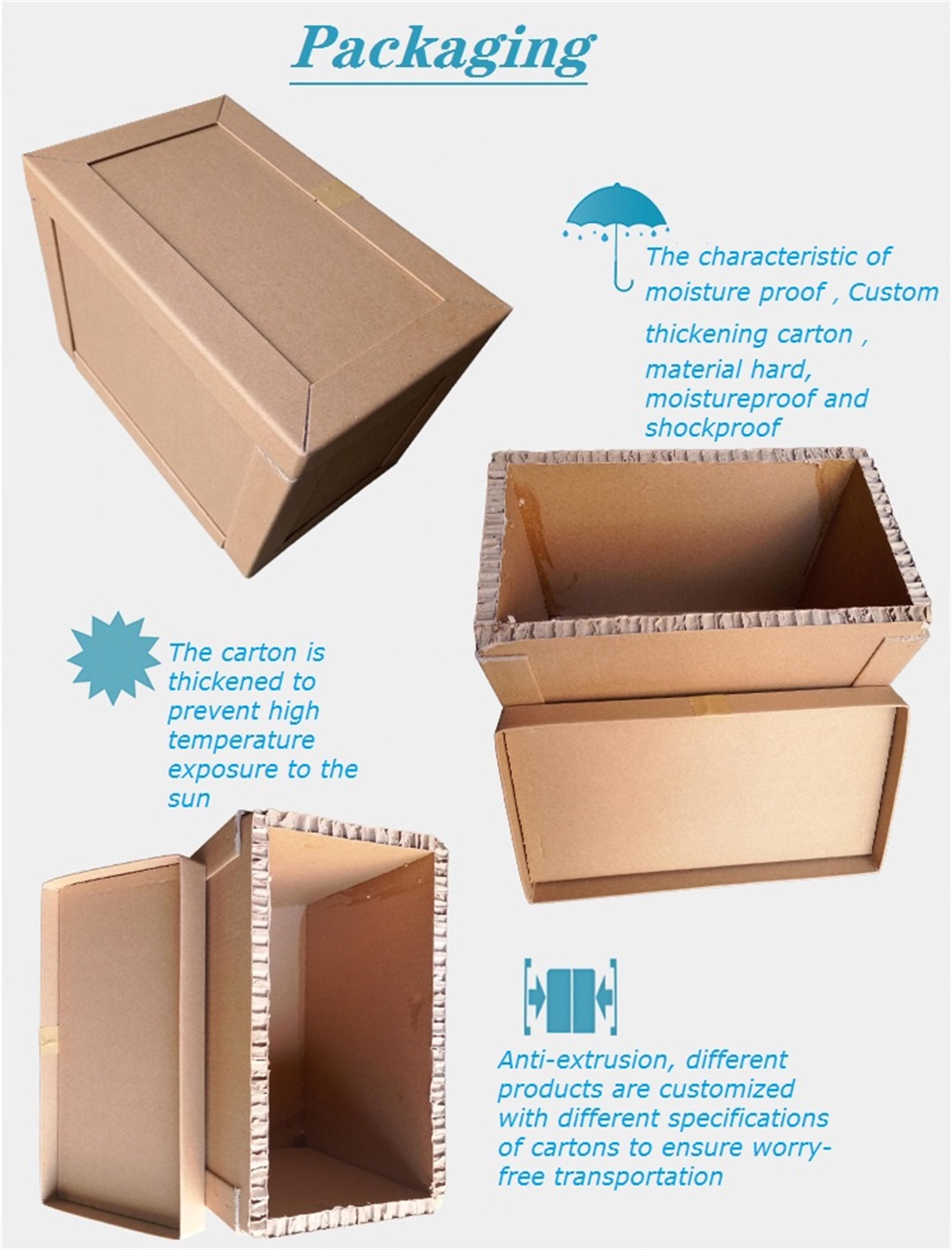

Ukupakishwa kwemveliso

Ityala lesicelo semveliso