I-CKSC 3-180KVA 50-3000Kvar yamanqanaba amathathu aphezulu ombane owomileyo uthotho lwereactor yekhabhathi yecapacitor

Ingcaciso yeMveliso

Uhlobo lwe-CKSC lwe-iron eyomileyo yoluhlu lwe-reactor sisixhobo esibalulekileyo sokuxhasa isixhobo sembuyekezo yamandla asebenzayo wenkqubo yamandla.Emva kokuba i-capacitor yamandla iqhagamshelwe kuthotho kunye ne-iron-core reactor eyomileyo, inokucinezela ngokufanelekileyo i-harmonics yomyalelo ophezulu kwigridi yamandla, ukunciphisa i-inrush yangoku kunye nokugqithiswa kokusebenza, ukuphucula i-voltage waveform yenkqubo, ukuphucula amandla ombane wegridi yamandla, kunye nokunciphisa impembelelo ye-capacitors yamandla kunye namanye amandla Ukusebenza ngokukhuselekileyo kwesixhobo kudlala indima enkulu.

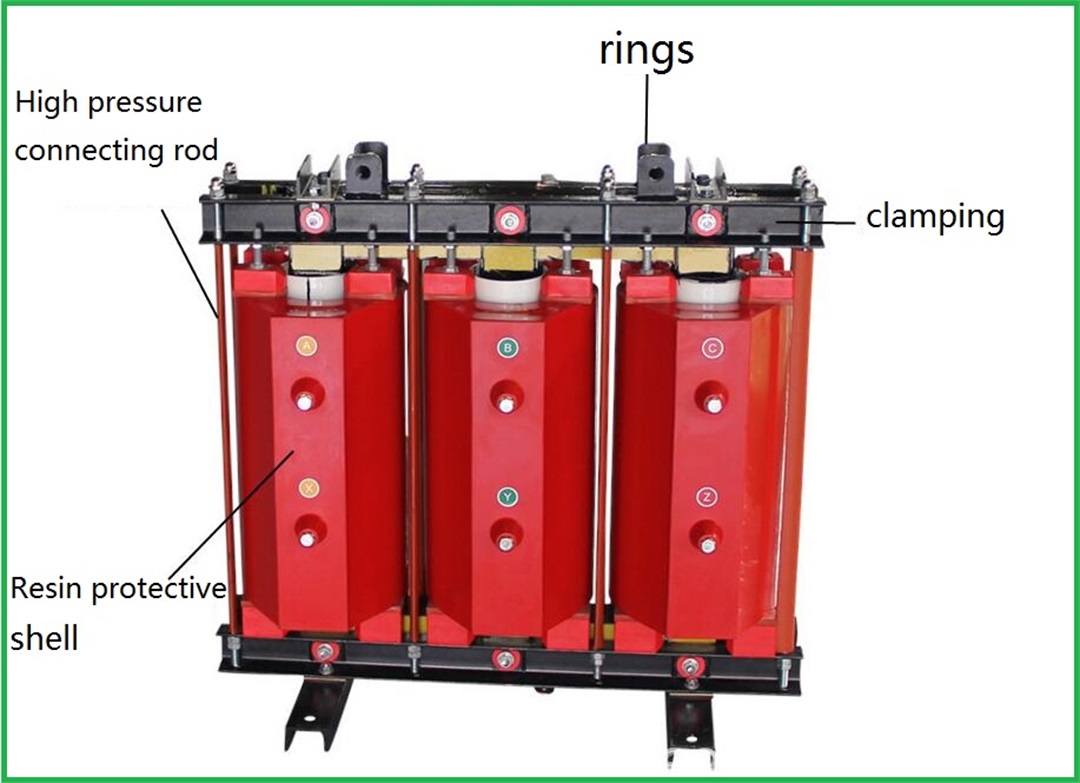

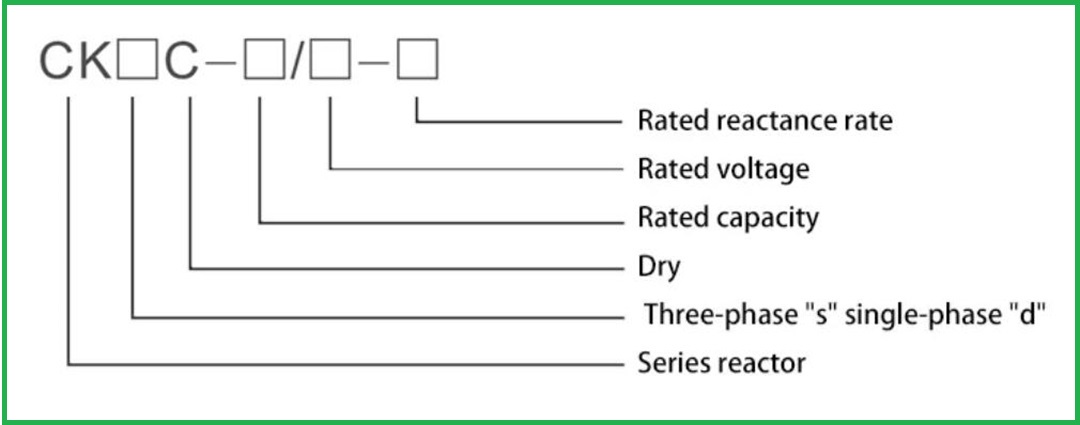

Inkcazo yoMfanekiso

Iimpawu zemveliso kunye nobungakanani bokusetyenziswa

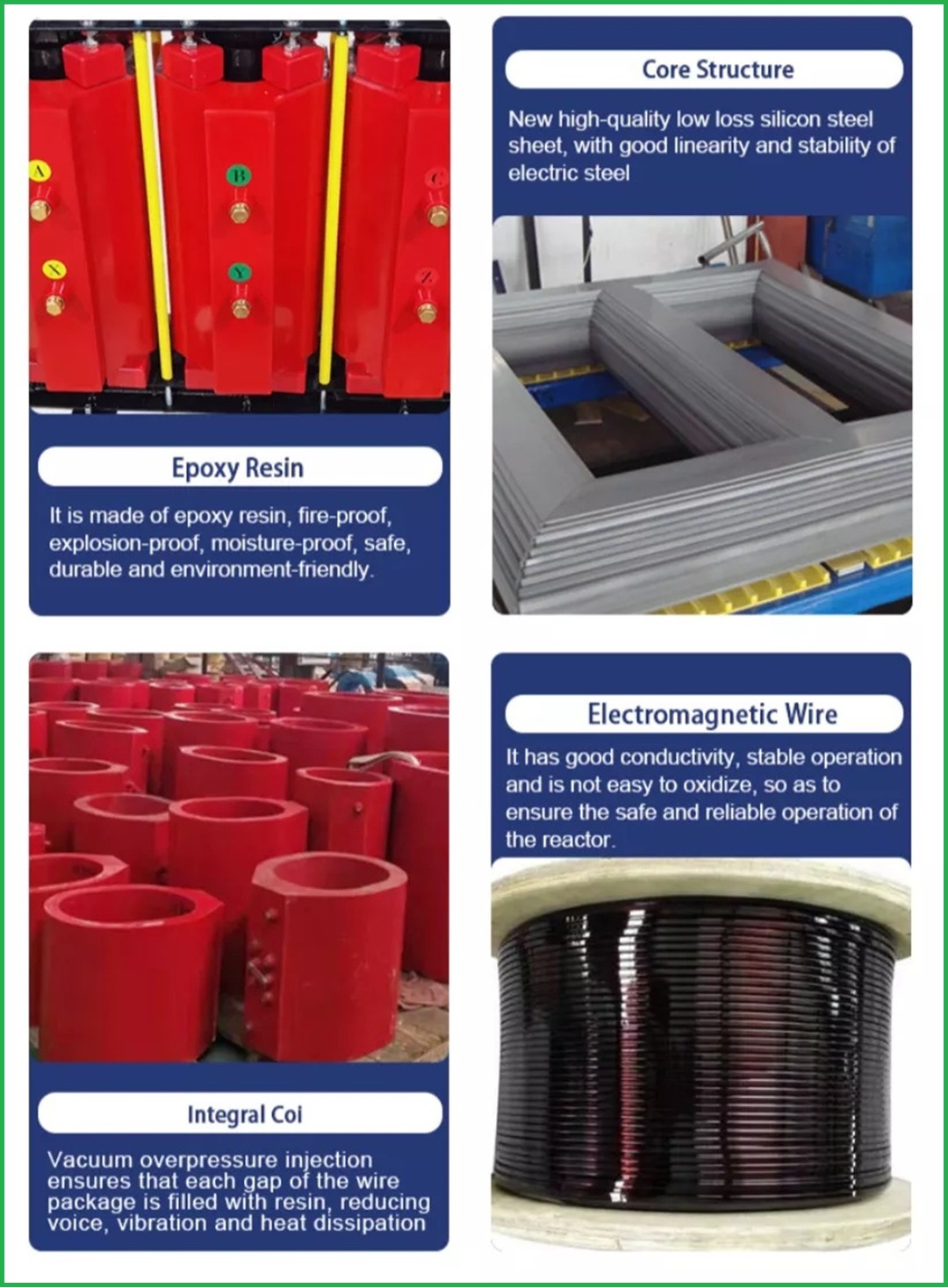

1. Undoqo wentsimbi ye-CKSC eyomileyo yohlobo lwentsimbi ye-reactor ithatha umgangatho ophezulu we-silicon yentsimbi ephuma kumazwe angaphandle, ikholamu engundoqo yahlulwe yangamacandelo amancinci amancinci ngokusebenzisa izikhewu ezininzi zomoya, kwaye umsantsa womoya wodwa yibhodi yelaphu ye-epoxy ukuqinisekisa ukusebenza kwexesha elide kwesithuba somoya kwi-reactor.phantsi ngaphandle kokutshintsha.

2. Isiphelo sobuso be-iron core senziwe nge-high-quality silicon sheet sheet face glue, ukwenzela ukuba i-silicon sheet sheet idibaniswe ngokuqinileyo, eyanciphisa kakhulu ingxolo ngexesha lokusebenza, kwaye inomswakama omhle kunye nokusebenza kothuli.

3. Ikhoyili yohlobo lwe-epoxy casting, kunye ne-epoxy glass mesh cloth ibekwe ngaphakathi nangaphandle kwekhoyili ukuze iqiniswe.Inkqubo yokuphosa ye-epoxy ye-F-class isetyenziselwa ukuphosa kwimeko ye-vacuum.I-coil ayinayo kuphela ukusebenza kakuhle kwe-insulation, kodwa inamandla amakhulu omatshini kwaye inokumelana nokutshatyalaliswa kwangoku okuphezulu kunye nokutshisa okutshisa kunye nokubandayo ngaphandle kokuqhekeka.

4. I-epoxy casting coil ayifuni amanzi, inokukhutshwa okuncinci, kwaye inokusebenza ngokukhuselekileyo kwiimeko ezinzima zokusingqongileyo.

5. Iziphelo eziphezulu kunye nezisezantsi zekhoyili zenziwe ngamacwecwe e-epoxy kunye ne-silicone i-rubber shock-proof pads, enciphisa ngempumelelo i-vibration yekhoyili ngexesha lokusebenza.

6. Xa kuthelekiswa ne-reactors yendabuko ye-oyile kunye ne-air-core reactors, i-reactors eyomileyo incinci ngobukhulu, kwaye ineempawu zobunzima bokukhanya, unyawo oluncinci, isakhiwo esilula kunye nofakelo olufanelekileyo.

7. Inqanaba lokumelana nobushushu lifikelela kwiklasi F (155℃);ngexesha lokusebenza okuqhelekileyo, ukunyuka kweqondo lobushushu kwintsimbi yentsimbi kunye nekhoyili ye-iron core reactor eyomileyo ayidluli i-90K.

8. Udidi olumileyo lwe-iron core reactor lunokuhamba ixesha elide kwi-1.35 yamaxesha angoku.

9. Ingxolo yentsimbi eyomileyo yohlobo lwentsimbi ayikho mkhulu kunomgangatho woshishino.

10. Umgangatho wokumelana ne-voltage ye-dry-type iron-core reactors ihambelana nemimiselo ye-JB5346-1998 "Series Reactors".

Iimeko zokusebenza ezisebenzayo

(1) Ukuphakama ≤ 1500 yeemitha

(2) Ubushushu be-Ambient -25℃~+40℃

(3) Ukufuma okuhambelanayo≤90%

(4) Akukho gesi edlayo okanye enokutsha kumoya ojikelezileyo, akukho lungcoliso lucacileyo olufana nomphunga wamanzi.

(5) Akukho kushukuma okunobundlobongela rhoqo kunye nokungena komoya olungileyo.

(6) Le reactor sisixhobo sangaphakathi.

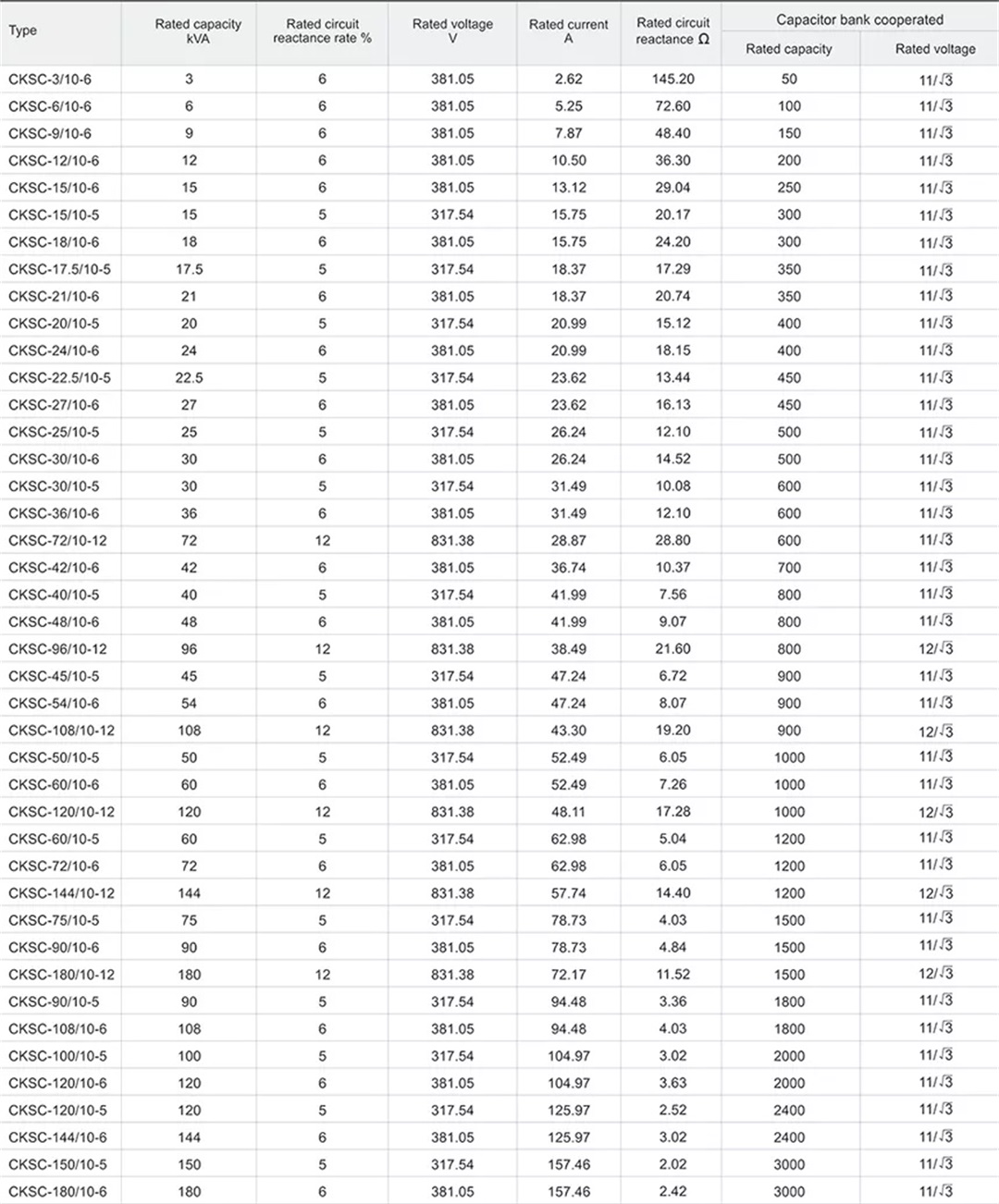

Ukuodola ulwazi

1. I-voltage elinganisiweyo yenkqubo;

2. Umthamo we-Capacitor;

3. I-Capacitor terminal voltage;

4. Izinga lokusabela;

5. Iindlela zokungena kunye nokuphuma kwimigca (icala eliphindwe kabini, icala elinye);

6. Ukuba kukho ezinye iimfuno ezizodwa, kufuneka ichazwe ngokucacileyo.

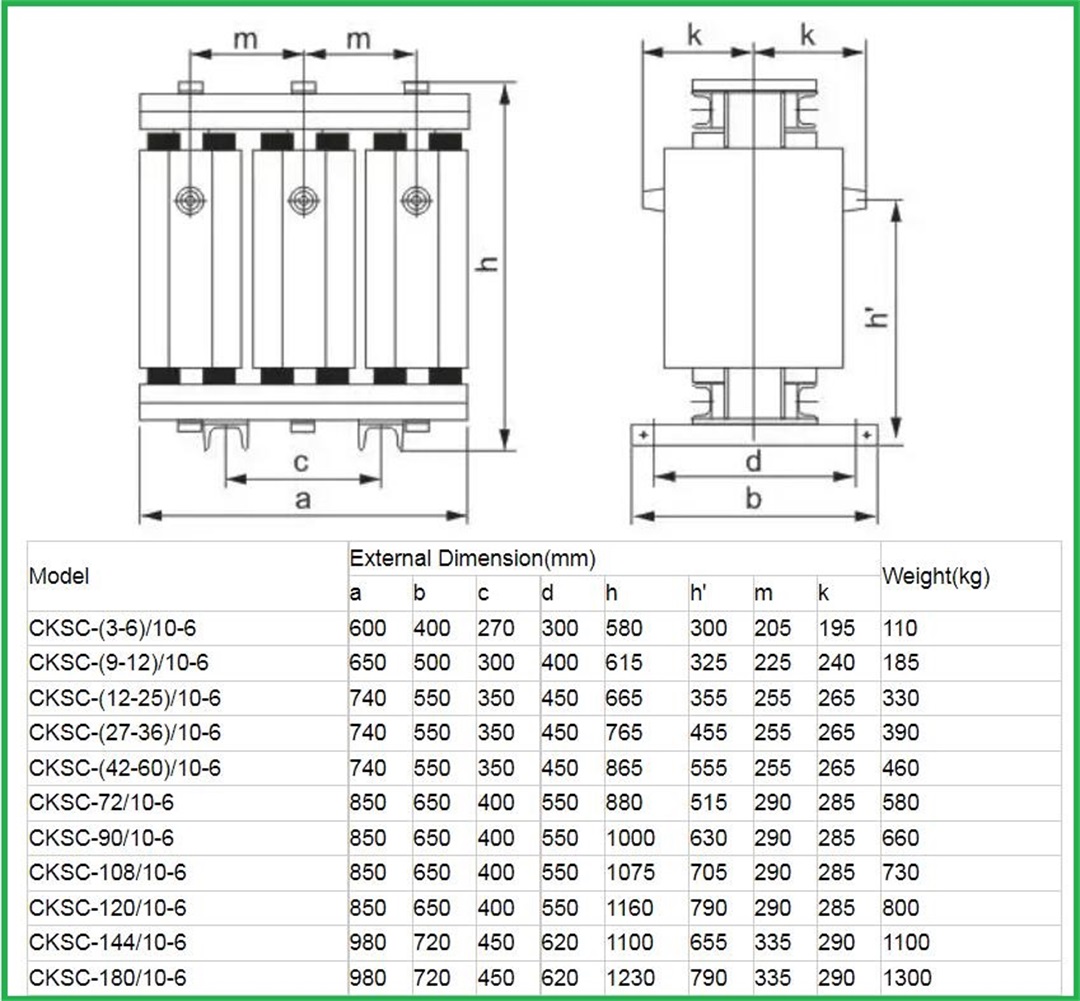

Iinkcukacha zemveliso

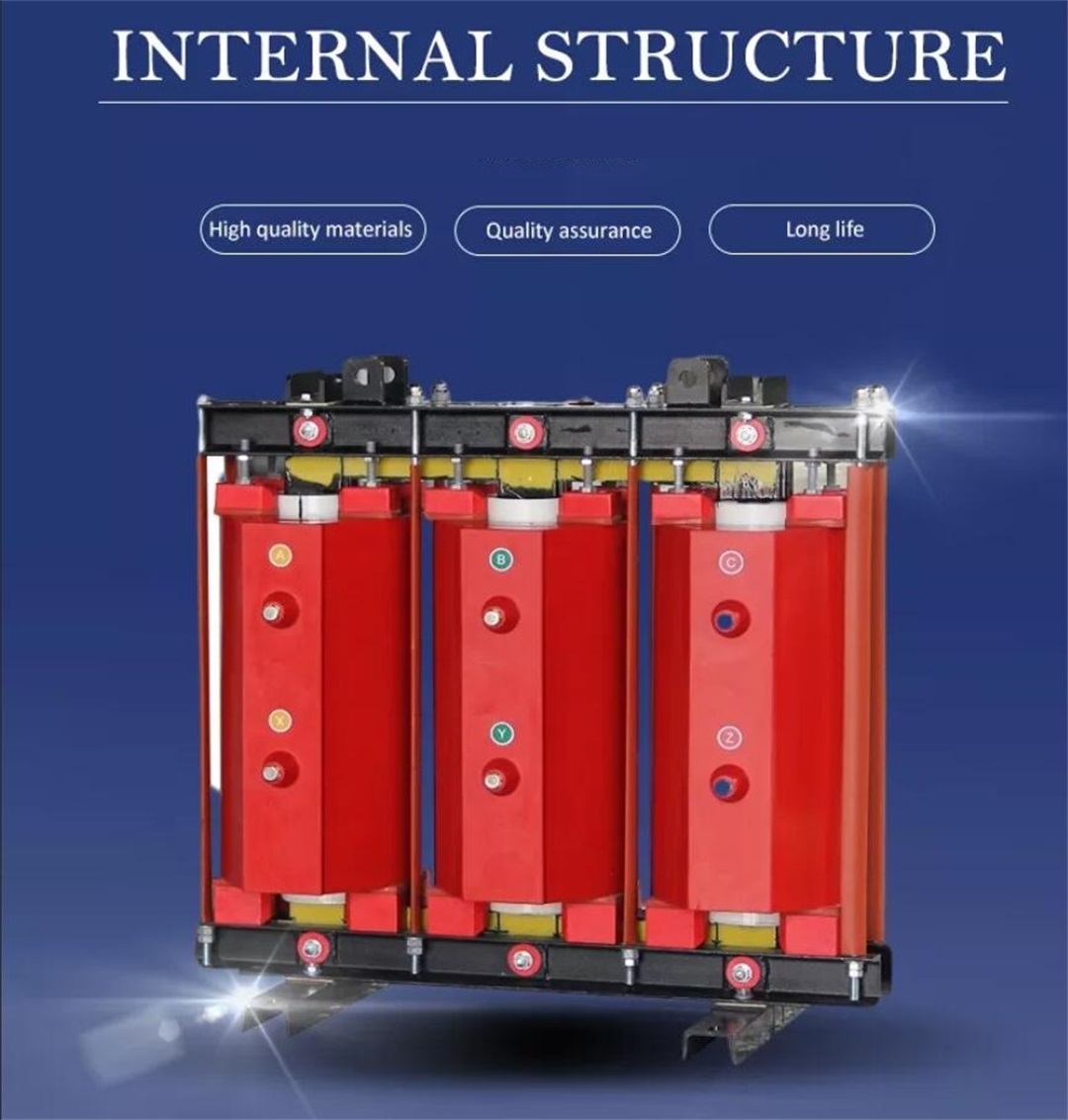

Iimveliso shot real

Ikona yocweyo lwemveliso

Ukupakishwa kwemveliso

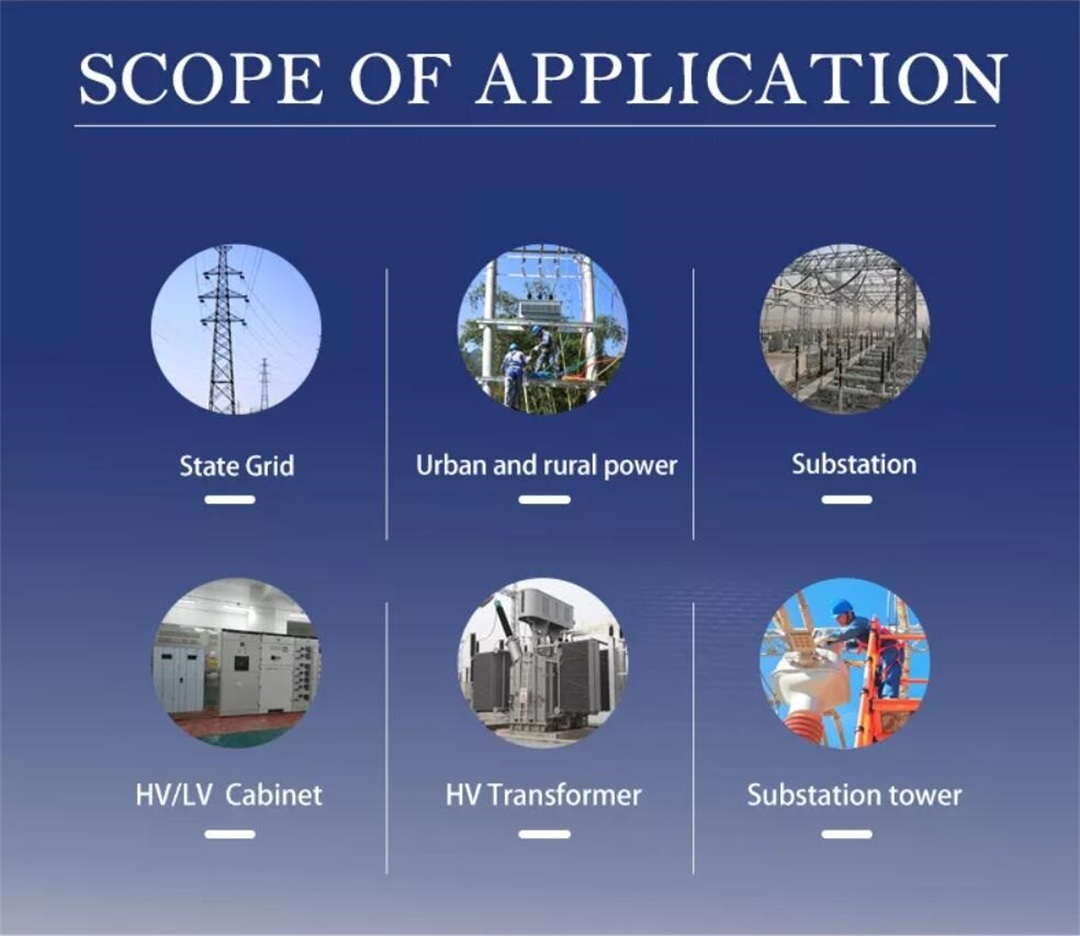

Ityala lesicelo semveliso