CKSC 3-180KVA 50-3000Kvar atatu gawo mkulu voteji youma mndandanda riyakitala capacitor nduna

Mafotokozedwe Akatundu

CKSC mtundu wachitsulo chowuma pachimake riyakitala ndi chida chofunikira chothandizira pazida zolipirira mphamvu zamagetsi.Pambuyo capacitor mphamvu chikugwirizana mu mndandanda ndi youma-mtundu chitsulo-pachimake riyakitala, akhoza bwino kupondereza mkulu-kuti harmonics mu gululi mphamvu, kuchepetsa kutseka inrush panopa ndi ntchito overvoltage, kusintha voteji waveform wa dongosolo, kusintha. mphamvu yamagetsi a gridi yamagetsi, ndi kuchepetsa mphamvu ya capacitors mphamvu ndi mphamvu zina Kugwira ntchito kotetezeka kwa zipangizo kumagwira ntchito yaikulu.

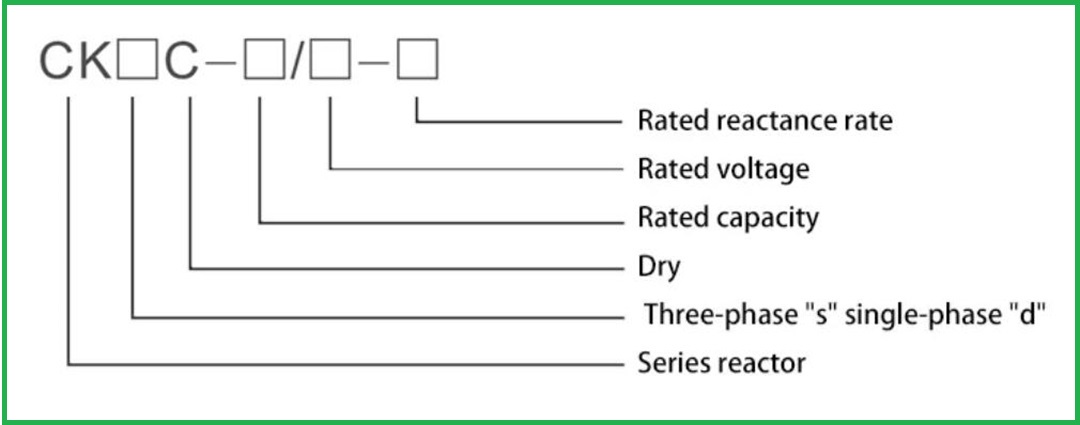

Kufotokozera Kwachitsanzo

Zogulitsa ndi kuchuluka kwa ntchito

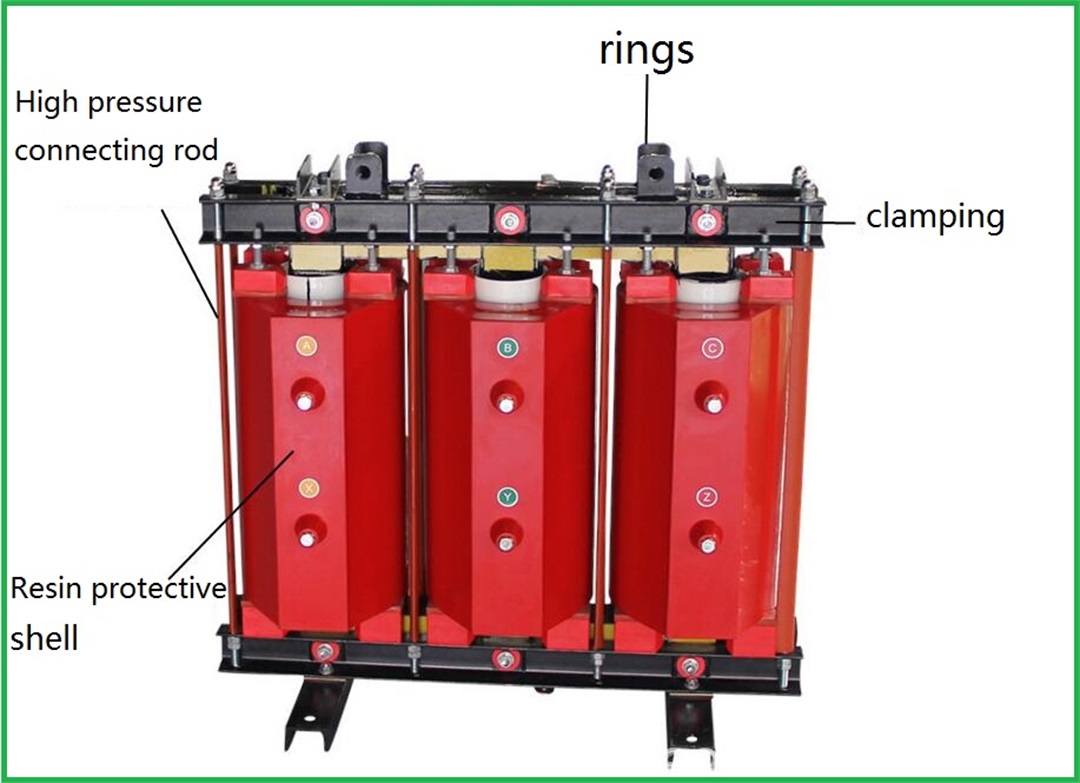

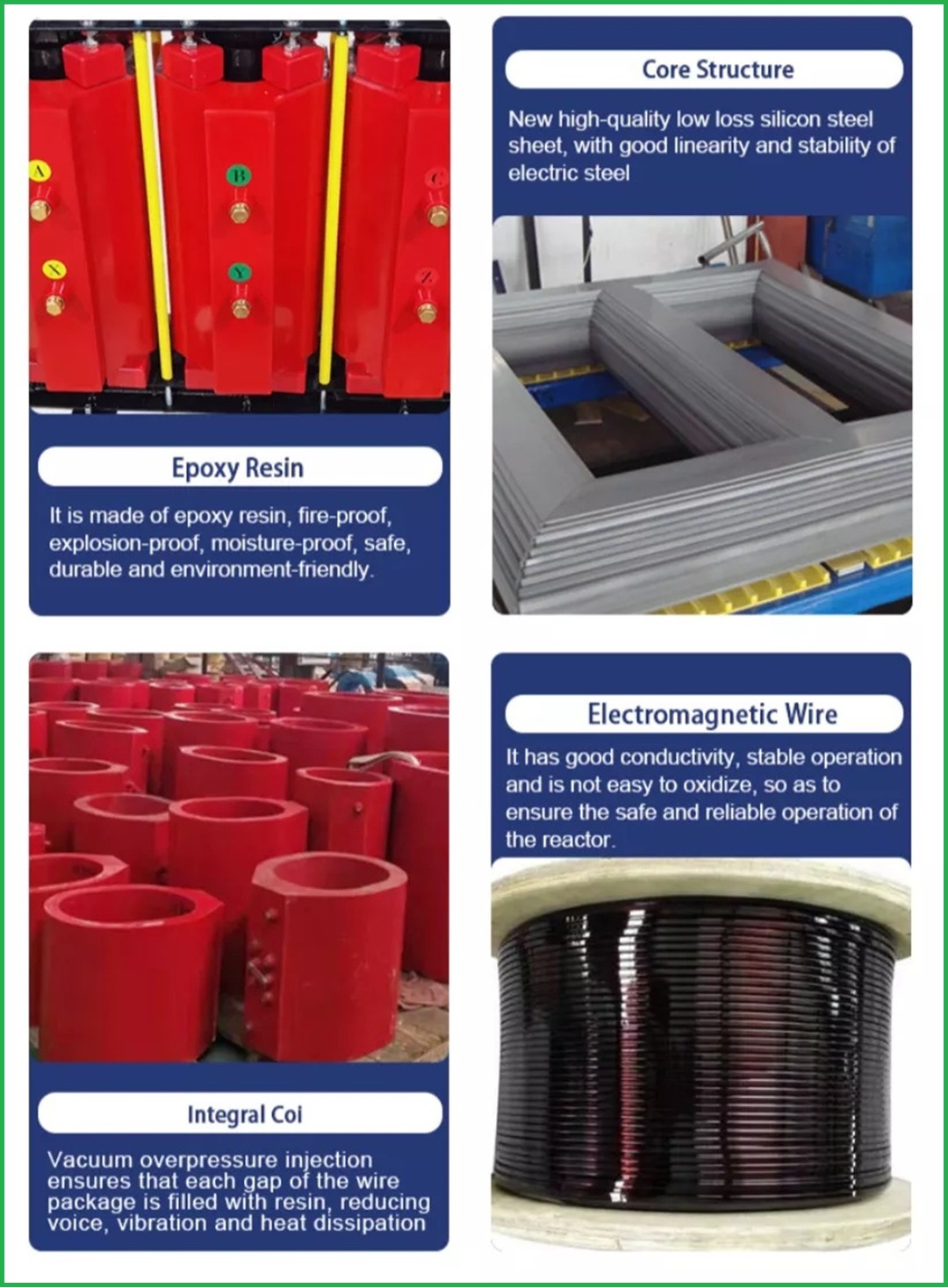

1. Pachimake chitsulo cha CKSC youma-mtundu chitsulo pachimake riyakitala utenga apamwamba kunja silikoni zitsulo pepala, pachimake ndime imagawidwa m'magawo ang'onoang'ono yunifolomu kudzera mipata angapo mpweya, ndi mpweya kusiyana ndi olekanitsidwa ndi epoxy nsalu bolodi kuonetsetsa ntchito yaitali ya mpweya kusiyana riyakitala.pansi popanda kusintha.

2. Kumapeto kwa chitsulo chachitsulo kumapangidwa ndi mapepala apamwamba a silicon chitsulo kumapeto kwa nkhope ya glue, kotero kuti pepala lachitsulo la silicon likhale logwirizana kwambiri, lomwe limachepetsa kwambiri phokoso panthawi yogwira ntchito, ndipo limakhala ndi chinyezi chabwino komanso fumbi.

3. Koyiloyo ndi yamtundu wa epoxy casting, ndipo nsalu ya epoxy glass mesh imayikidwa mkati ndi kunja kwa koyilo kuti ilimbikitse.F-class epoxy casting system imagwiritsidwa ntchito poponya mu vacuum state.Koyiloyo sikuti imakhala ndi ntchito yabwino yotchinjiriza, komanso imakhala ndi mphamvu zamakina apamwamba ndipo imatha kupirira Kugwedezeka kwamakono komanso kutentha komanso kuzizira popanda kusweka.

4. Koyilo yotulutsa epoxy simamwa madzi, imakhala ndi kutulutsa pang'ono pang'ono, ndipo imatha kugwira ntchito motetezeka m'malo ovuta kwambiri.

5. Mapeto a pamwamba ndi apansi a koyilo amapangidwa ndi mapepala a epoxy ndi mapepala a silicone mphira otsekemera, omwe amachepetsa bwino kugwedezeka kwa koyilo panthawi yogwira ntchito.

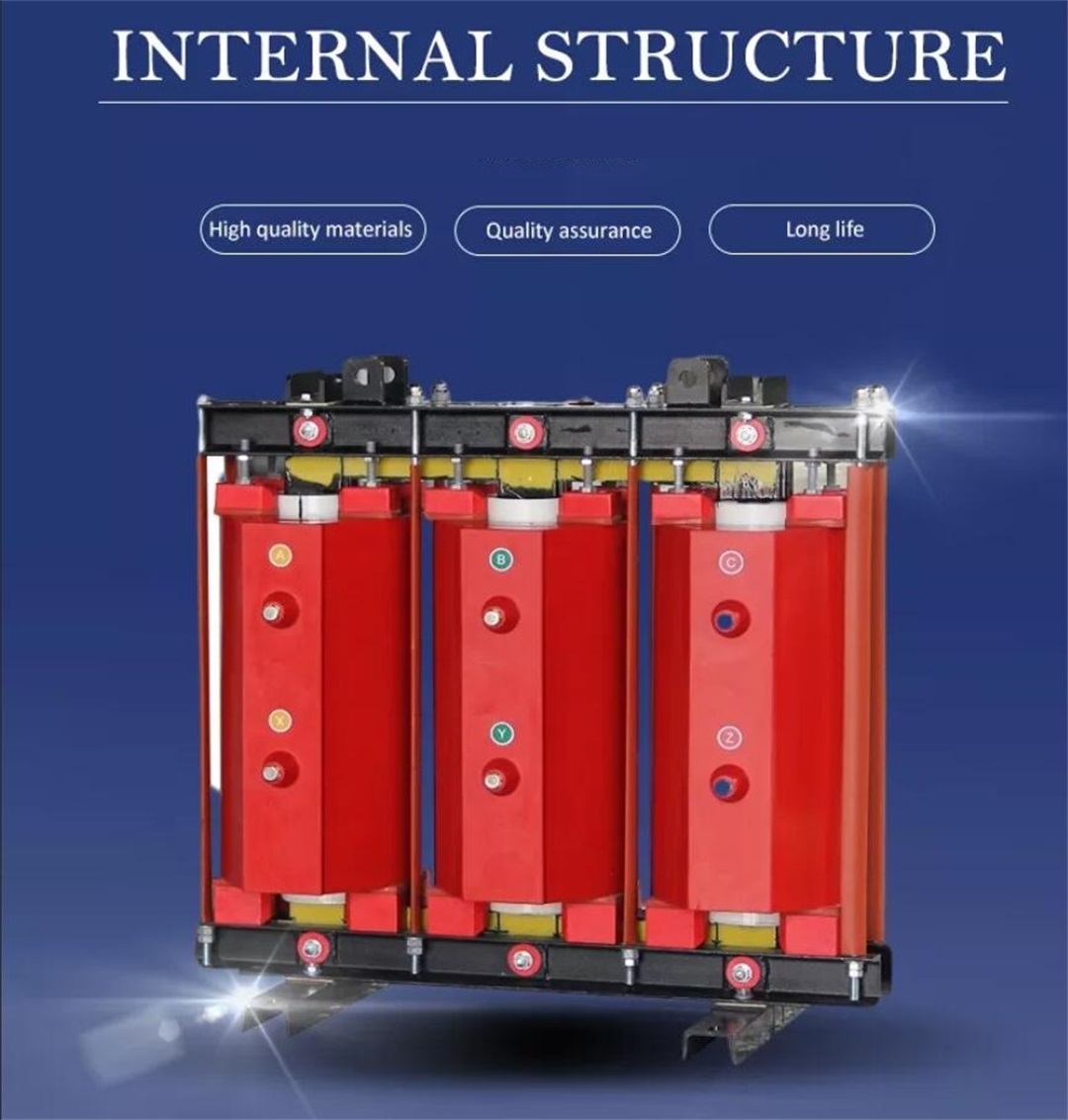

6. Poyerekeza ndi ma reactors achikhalidwe omizidwa ndi mafuta ndi ma air-core reactors, ma reactors amtundu wowuma ndi ang'onoang'ono kukula, ndipo amakhala ndi mawonekedwe a kulemera kopepuka, phazi laling'ono, kapangidwe kosavuta komanso kukhazikitsa kosavuta.

7. Kutentha kwa kutentha kumafika m'kalasi F (155 ℃);pa ntchito yachibadwa, kutentha kuwuka kwa chitsulo pakati ndi koyilo ya youma-mtundu chitsulo pachimake riyakitala si upambana 90K.

8. Chitsulo chachitsulo chowuma chamtundu wouma chimatha kuthamanga kwa nthawi yaitali pa 1.35 nthawi yomwe idavotera panopa.

9. Phokoso la chitsulo chowuma chamtundu wouma sichili chachikulu kuposa muyezo wamakampani.

10. Kupirira kwamphamvu kwa magetsi owuma amtundu wachitsulo-core reactors kumagwirizana ndi zomwe JB5346-1998 "Series Reactors".

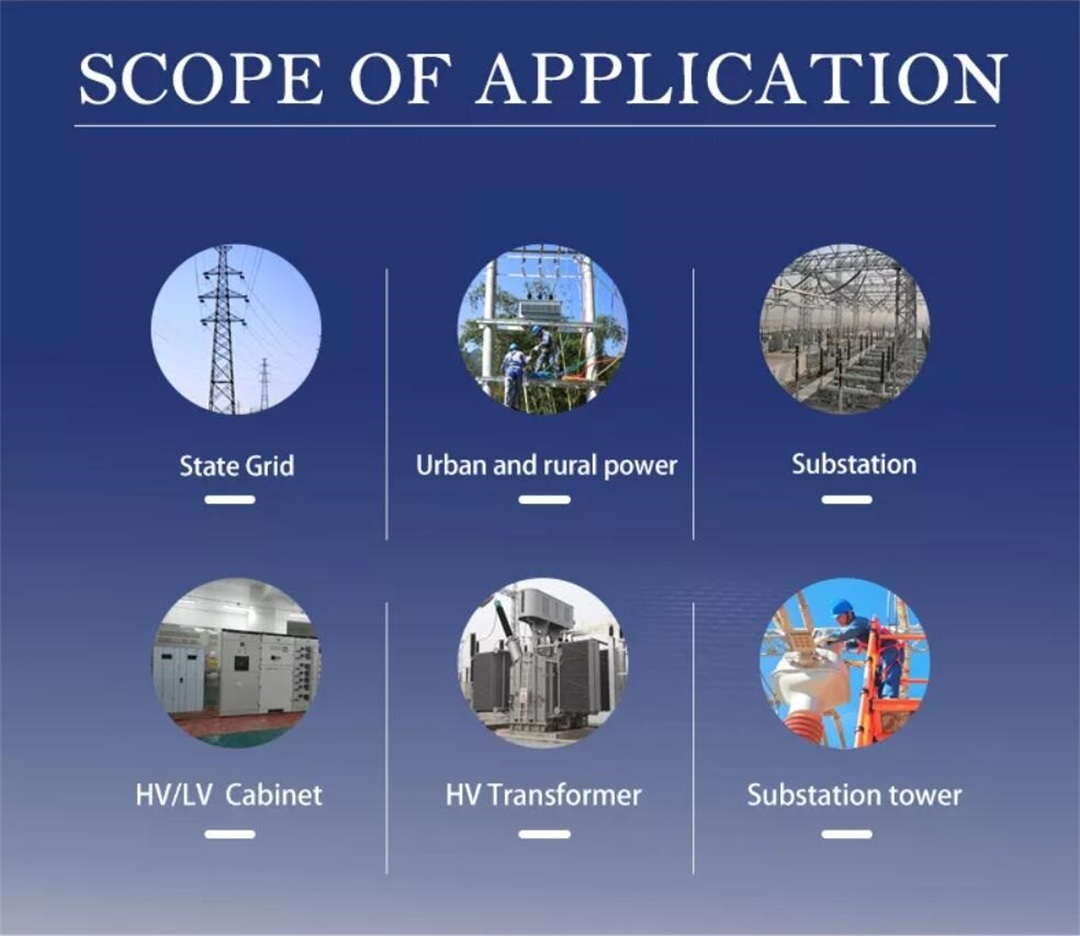

Zovomerezeka zogwirira ntchito

(1) Kutalika ≤ 1500 mamita

(2) Kutentha kozungulira -25℃~+40℃

(3) Chinyezi chachibale≤90%

(4) Palibe mpweya wowononga kapena woyaka mumlengalenga wozungulira, palibe kuipitsidwa koonekeratu monga mpweya wamadzi.

(5) Palibe kugwedezeka kwachiwawa pafupipafupi komanso mpweya wabwino.

(6) Rector iyi ndi chipangizo chamkati.

Kuyitanitsa zambiri

1. Mphamvu yamagetsi yamagetsi;

2. Mphamvu ya capacitor;

3. Capacitor terminal voltage;

4. Reactance rate;

5. Njira zolowera ndi kutuluka mizere (awiri-mbali, mbali imodzi);

6. Ngati pali zofunikira zina zapadera, ziyenera kunenedwa momveka bwino.

Zambiri zamalonda

Zogulitsa zenizeni

Ngodya ya msonkhano wopanga

Kupaka katundu

Mlandu wofunsira mankhwala