FFM 4.62/6.9/11√3/35√3KV 0.1-25kvar High Voltage Protection Power Capacitor

Product Description

The protective capacitor is connected in parallel with the vacuum switch. When the vacuum switch is connected to the inductive load, it can not only limit the operating overvoltage to a certain range, but also delay the rise time of the cut-off overvoltage and the re-ignition overvoltage wave head and reduce the steepness, thereby protecting the The electrical equipment is insulated from the impact of the steep wave front.

It is used in 50Hz, 3kV, 6kV, 10kV, 35kV power systems to form a resistance-capacitance absorber with a resistor. It uses the energy absorbed by the capacitor to reduce the voltage amplitude and the damping effect of the resistor to attenuate the oscillation and prevent overvoltage. The grounding mode of the neutral point is limited to ensure that it matches the insulation level of the motor and improves the power supply quality of the power grid.

In other occasions, it can also be used as a high-voltage capacitor. When connected between lines and ground, it can reduce atmospheric overvoltage, wavefront steepness and peak-to-peak value.

It can protect electrical equipment when used with arrester; it is a matching capacitor for RC overvoltage absorption device of vacuum circuit breaker system.

Model Description

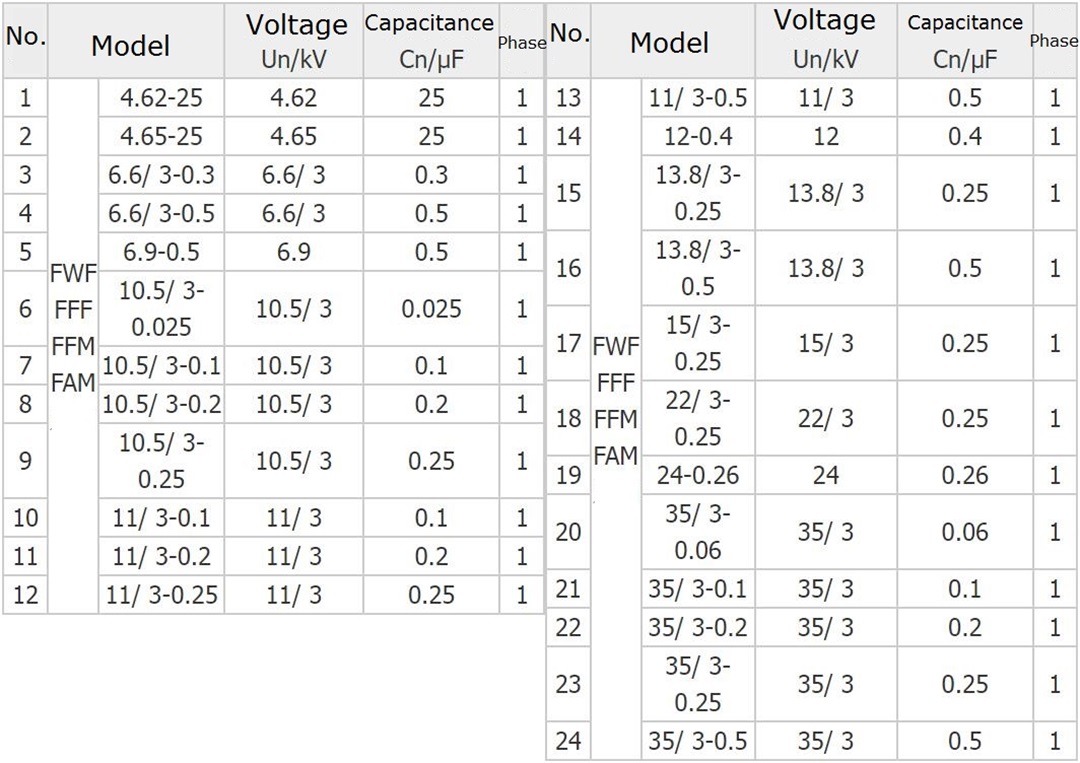

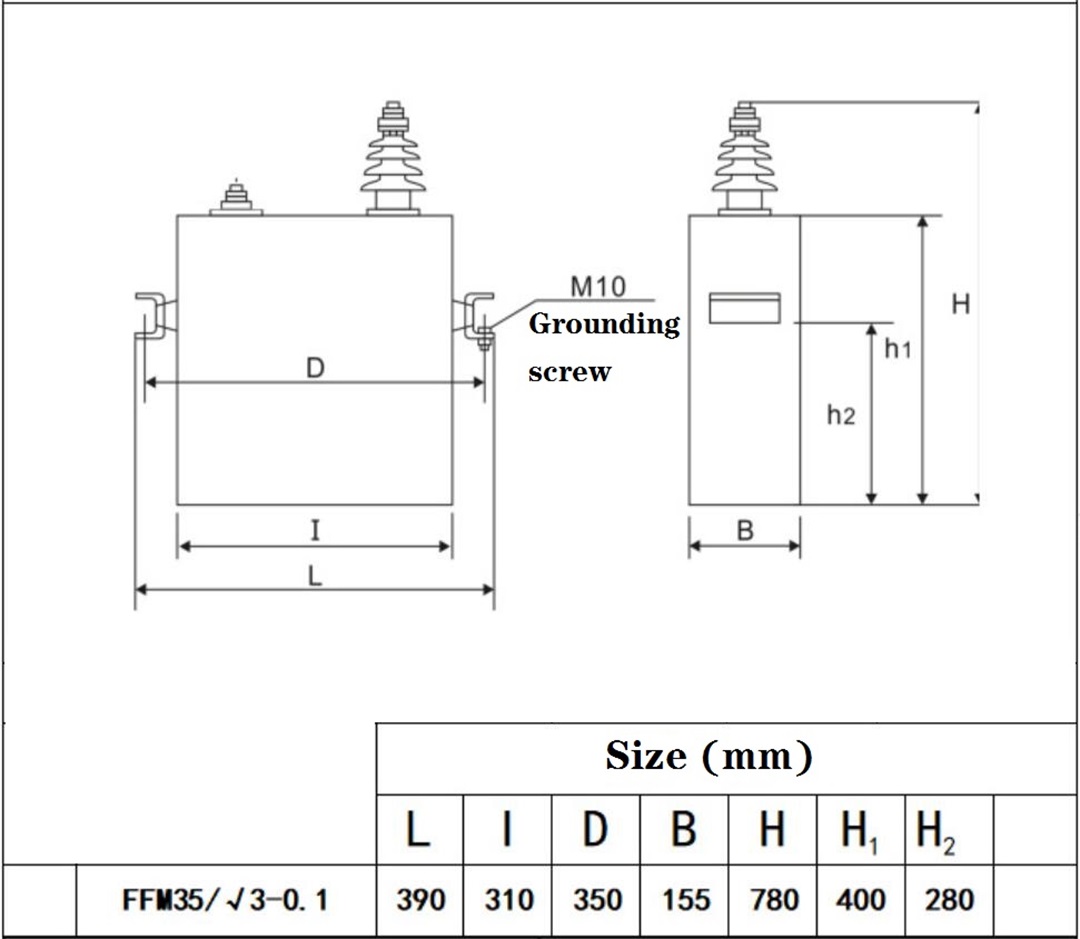

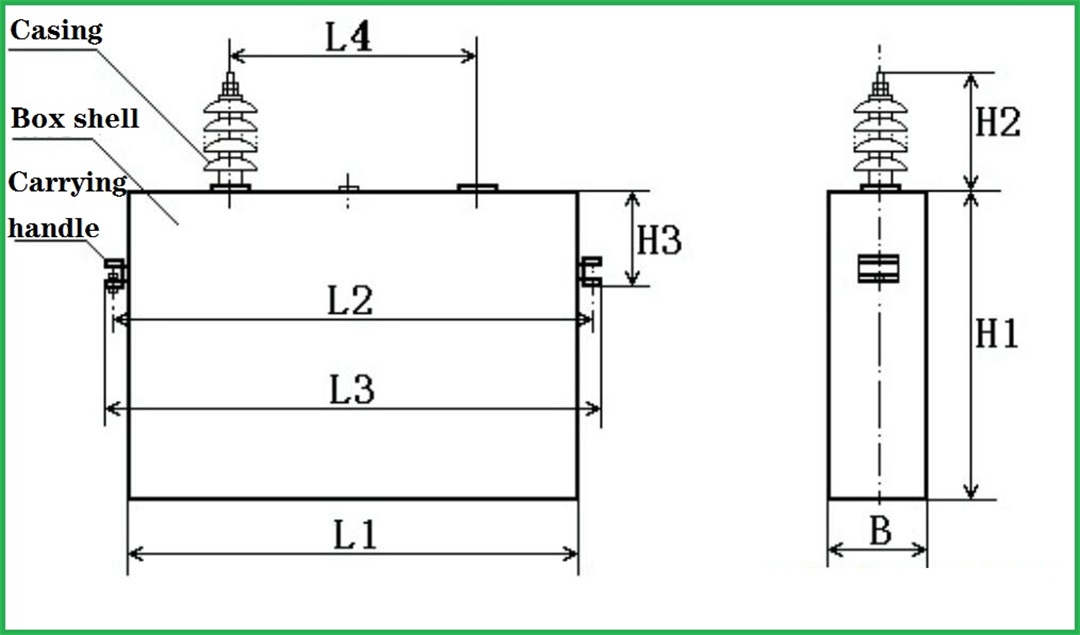

Technical parameters and structure dimensions

■Technical performance

●Capacitance deviation: -5%~+10%.

●Dielectric loss tangent value tanδ

Under rated voltage Un, at 20℃:

A. For film-paper composite media: tanδ≤0.002.

B. For full film medium: tanδ≤0.0005.

●Rated frequency: fn=50Hz.

●The capacitor can run for a long time under 1.1Un, and can withstand the operating overvoltage caused by the opening and closing of the circuit breaker with the first peak value ≤2.5 2Un.

●The capacitor can run for a long time under 1.5In, this current includes the current caused by steady-state overvoltage, also includes the current caused by harmonics, and also includes the current increased by the capacitance deviation.

●Cooling method: natural convection of air on the surface of capacitor shell.

●The altitude of the installation and operation area shall not exceed 1000m; the ambient air temperature range of the installation and operation area: indoor -40~+45℃; air relative humidity ≤95%.

●The installation and operation place should be free of corrosive gas and steam; no conductive or explosive dust and severe mechanical vibration.

●There should not be a lot of dust and dirt on the surface of the ceramic sleeve of the capacitor. If oil leakage is found, the operation must be stopped.

Product features and scope of use

The capacitor is mainly composed of a shell and a core. The shell is welded by a thin steel plate, the cover contains a wire outlet porcelain sleeve, and both sides of the wall are welded with Angle plates for installation. The core is assembled into a whole by a component, an insulating part and a tight hoop, and the component medium is coiled with an electrode separated by it.

High-quality and high-performance insulating materials are selected as solid media, and a special high-vacuum evaporation process is used to evaporate the metal to form a specific motor structure. It is made into a capacitor unit on an automatic rolling machine, and then made into a capacitor with a patented technology, and then used in series with a special non-inductive resistor.

Working conditions:

1. Ambient air temperature range: -40~+45℃, relative humidity not more than 95%.

2. There is no corrosive gas and steam in the installation site, no conductive or explosive dust and severe mechanical vibration.

3. Installation method: vertical installation.

Ordering information

The selection of the rated voltage of the capacitor must be based on the network voltage. Considering that the input of the capacitor will increase the voltage, so when selecting the rated voltage of the capacitor, it is at least 5% higher than the network voltage ; when there is a reactor in the capacitor circuit, the terminal voltage of the capacitor The ground increases with the reactance rate of the reactor in series, so when selecting the rated voltage of the capacitor, it should be determined after calculation according to the reactance rate of the reactor in the string. Capacitors are low-impedance channels of harmonics. Under harmonics, a large amount of harmonics will be injected into the capacitors to make the capacitors overcurrent or overvoltage. In addition, the capacitors will amplify the harmonics and cause resonance when they expire, endangering the safety of the power grid and making the capacitors lifespan. Therefore, capacitors with large harmonics must be used under reactors that suppress harmonics. The inrush current when the capacitor is closed can be as high as hundreds of times of the rated current of the capacitor. Therefore, the switch for switching the capacitor should choose a switch without re-breakdown. In order to suppress the closing inrush current, a reactor that suppresses the inrush current can also be connected in series. After the capacitor with internal discharge resistance is disconnected from the power supply, it can drop from the peak value of the rated voltage to below 75V within 10 minutes . be explained when. Capacitors used for line compensation should be installed at 150~200kvar in one place, and be careful not to install the capacitors on the same stage as the transformer, and do not use the same group of dropouts to prevent overshooting caused by ferromagnetic resonance when the line is not running in all phases. Current overvoltage can damage capacitors and transformers. The zinc oxide surge arrester for the protection of operating overvoltage should be selected for the zinc oxide surge arrester dedicated to the capacitor, and it is best to install it between the capacitor poles. The fuse specially used for capacitor is selected for quick-break, and the rated current should be selected according to to 1.42~1.5 times of the rated current of the capacitor. When the capacitor is directly connected to the high-voltage motor in parallel, in order to prevent self-excitation when the motor is disconnected from the power supply, causing the voltage of the capacitor terminal to rise greater than the rated value, the rated current of the capacitor must be less than 90% of the no-load current of the motor; When using Y/△ wiring, it is not allowed to connect the capacitor directly to the motor in parallel, and a special wiring method should be adopted. When the capacitor is used at an altitude higher than 1000 meters or the capacitor is used in the humid tropical zone, it should be stated when ordering. Special spe certifications or special requirements for capacitors should be specified when ordering.

Product details

Products real shot

A corner of the production workshop

Product packaging

Product application case