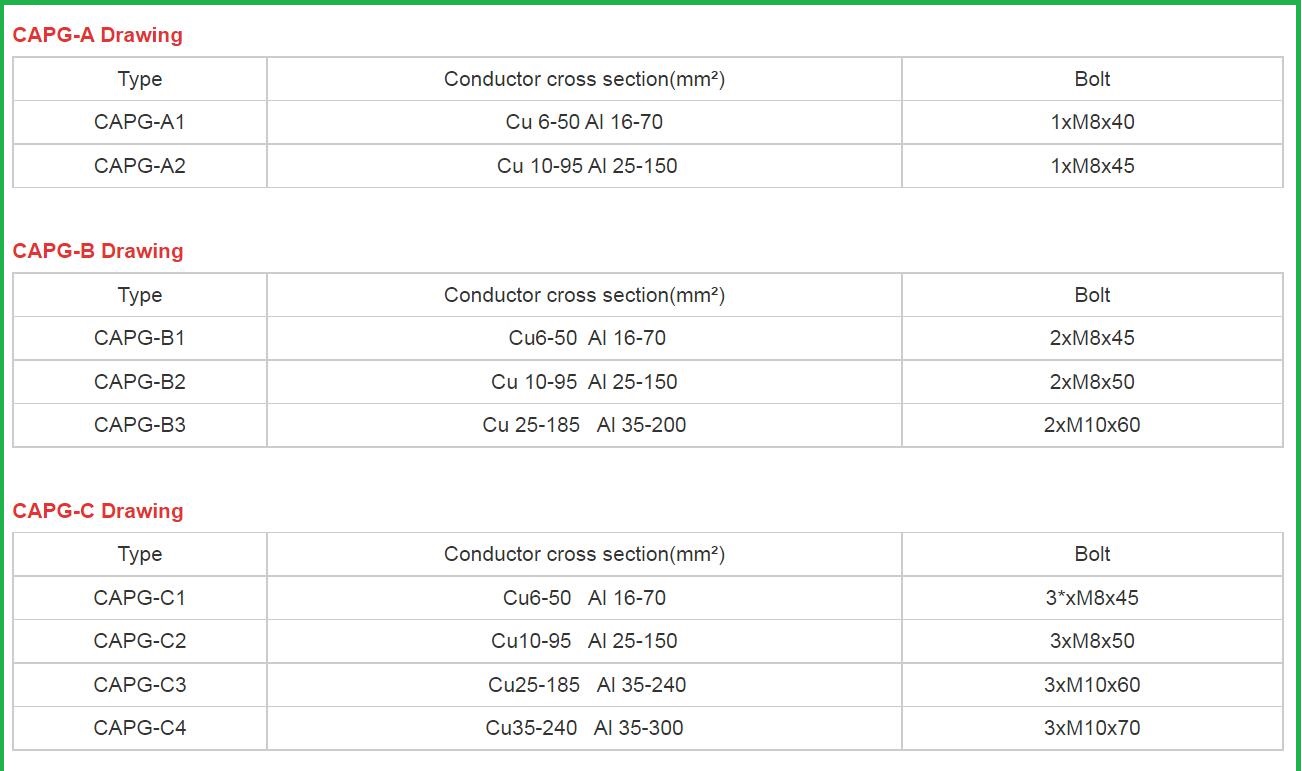

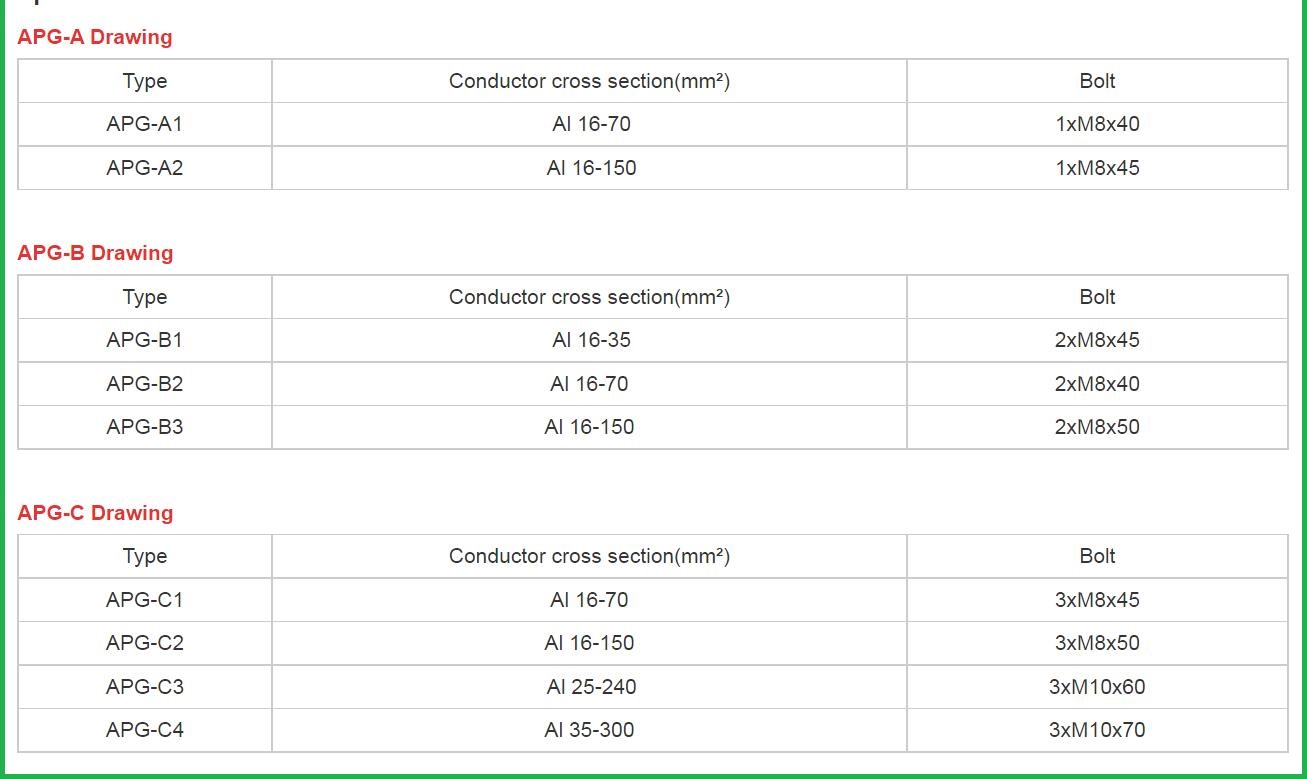

APG/CAPG 30KV and below 35-300mm² Cable connection branch clamp (Copper aluminum parallel groove connector)

Product Description

The parallel groove clamp is the most widely used power connection connector at present, the purpose is to connect two power transmission lines, so that the power transmission can continue. The power fitting is a weak link in the transmission and distribution line, and has high requirements for resistance. If the resistance is too large, the heating phenomenon during the operation of the line will obviously lead to the burning and fusing of the line, which will cause large-scale power outages and cause serious damage. Economic losses.

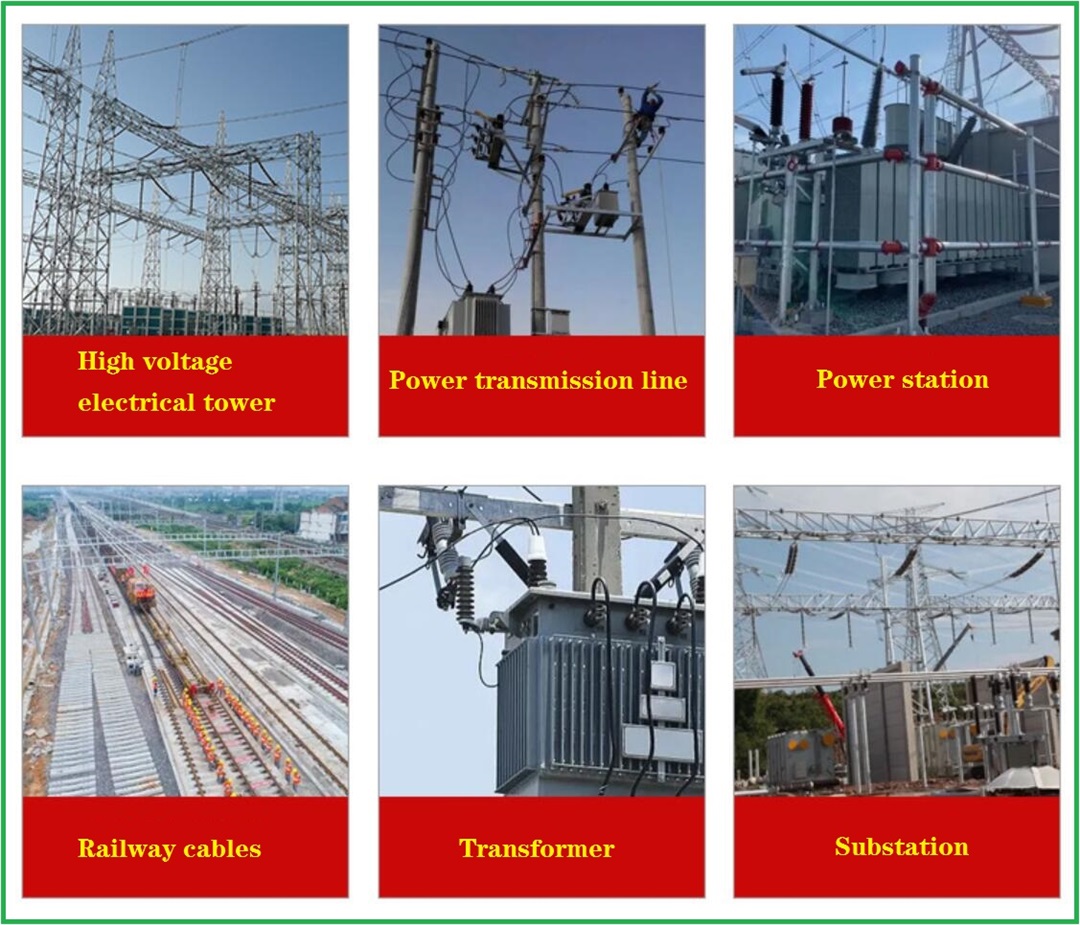

The parallel groove clamp is used for the connection of small and medium section aluminum stranded wire or steel core aluminum stranded wire and the steel stranded wire of the overhead lightning arrester at the position that does not bear the tension, and also used for the jumper connection of non-linear towers. Power engineering materials (fittings) are mainly used for connecting wires to connect to each other in power line engineering.

APG/CAPG series torque energy-saving parallel groove clamp is a brand-new non-load-bearing connection fittings, which are mainly used in power transmission, substation, and distribution line systems, and play the role of wire connection and jumper connection. The special alloy with high strength, high conductivity and intermediate electrode potential is processed by special process, and has good mechanical and electrical properties.

Product features and Installation matters

Features:

1. Light weight (weight ratio of the crimping sleeve to the weight of the grooved wire clamp = 1:8.836)

2. Less specifications, easy to carry, reduce labor intensity of construction personnel

3. Less construction time and convenient live work

4. Construction quality assurance (hydraulic clamp)

5. No need to apply anti-oxidant protective oil

Installation matters:

1. The degree of contamination of the contact surface when installing the parallel groove wire clip has a certain influence on the contact resistance. Before installing the wire clip, ensure that the wire groove is clean.

2. In the contact form of the parallel groove wire clip, the larger the contact area, the lower the contact resistance. When designing the wire clip, try to use surface contact and increase the contact area.

3. When the parallel groove clamp is installed, the greater the contact pressure, the smaller the contact resistance. Choose standard parts with well-processed and uniform coating, and apply conductive grease during installation, which can effectively improve the contact performance of the parallel groove clamp and reduce the contact resistance.

Product details

Products real shot

A corner of the production workshop

Product packaging

Product application case